Global emission regulations have accelerated the adoption of SCR (Selective Catalytic Reduction) technology across transportation and industrial sectors. At the core of this technology lies AdBlue®, a urea-based solution that significantly reduces nitrogen oxide (NOx) emissions.

To meet growing demand, many companies are shifting from purchasing ready-made AdBlue® to producing it internally using a reliable AdBlue® production system. An industrial AdBlue® production system enables controlled, on-site manufacturing of high-quality AdBlue, ensuring compliance, cost efficiency, and operational continuity. As emission standards become stricter and supply chain volatility increases, investing in a professional AdBlue® production system is no longer an option but a strategic necessity.

What Are AdBlue® Dissolving Systems?

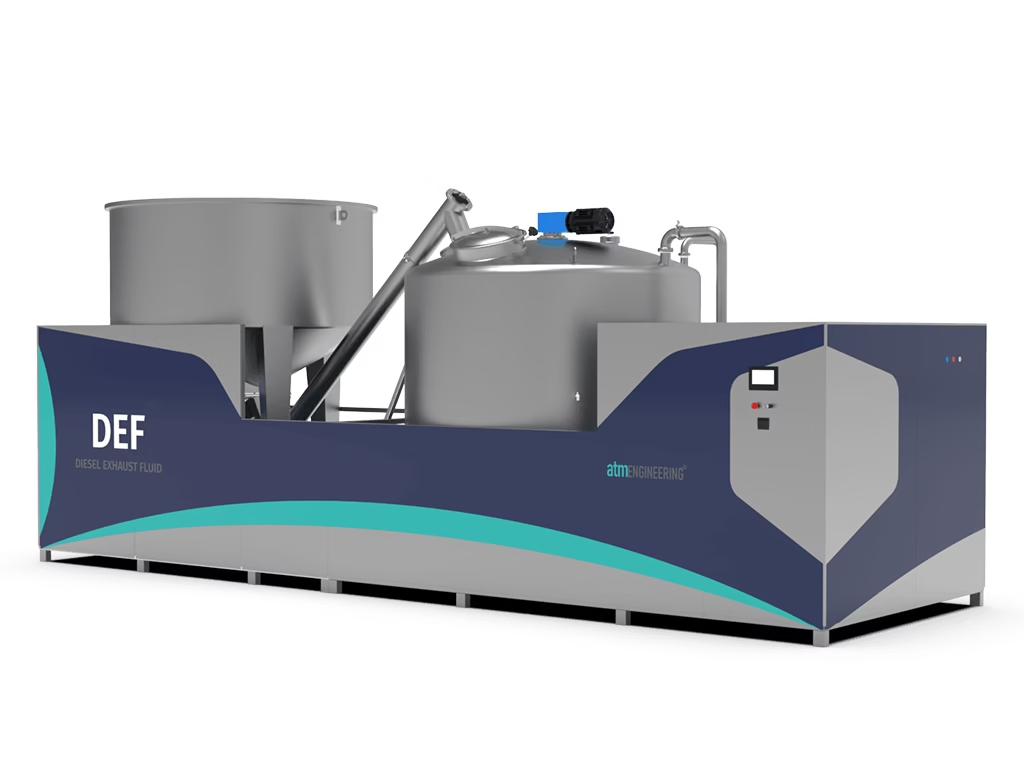

AdBlue® dissolving systems are specialized industrial installations designed to produce AdBlue® by dissolving solid automotive-grade urea into demineralized water at an exact concentration of 32.5%. These systems form the backbone of any modern AdBlue® production system, especially for high-volume or mission-critical operations.

Unlike manual or semi-automated methods, an industrial AdBlue® production system guarantees consistent quality, traceability, and compliance with ISO 22241 standards. This is particularly important for organizations operating vehicle fleets, logistics hubs, or industrial facilities where SCR performance directly impacts regulatory compliance.

Definition and Working Principle of AdBlue® Dissolving Systems

An AdBlue® dissolving system operates through a closed-loop, automated process. Solid urea is fed into a dissolution tank, where it is mixed with demineralized water under controlled temperature and agitation conditions. Sensors continuously monitor concentration, temperature, and conductivity to ensure the final solution meets required specifications. In a professional AdBlue® production system, every stage—from raw material intake to final storage—is engineered to prevent contamination and crystallization.

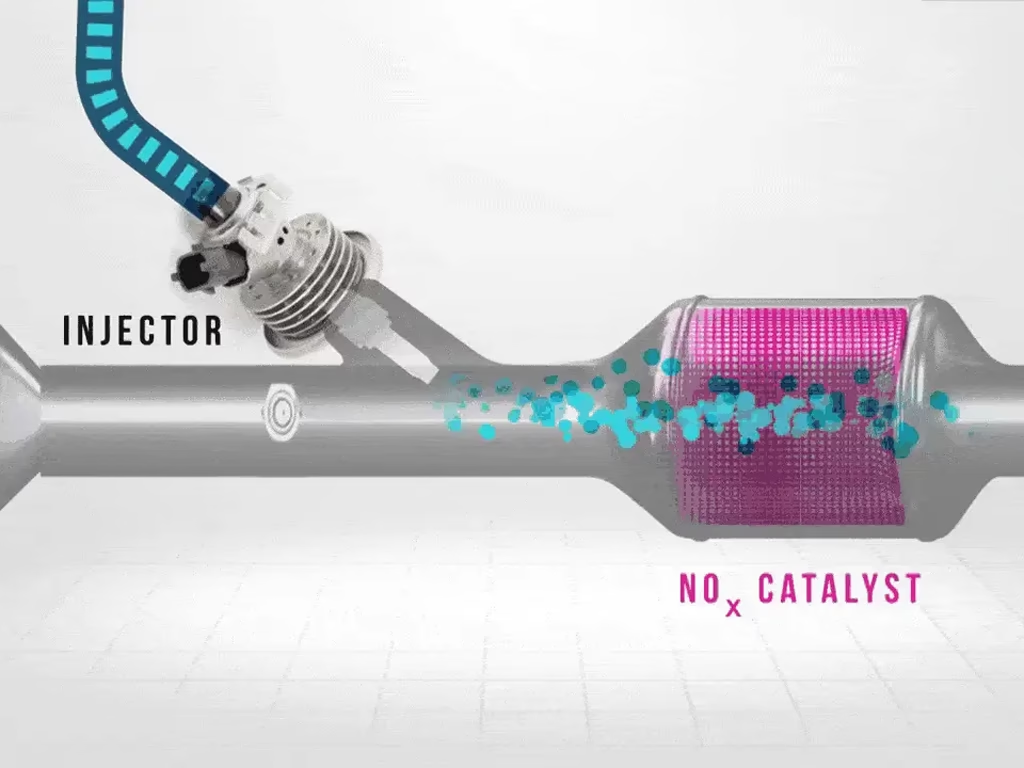

Automated dosing systems calculate the exact urea-to-water ratio, while filtration units remove any undissolved particles. The result is a homogeneous, high-purity AdBlue® solution ready for immediate use. The reliability of the AdBlue® production system directly affects SCR catalyst efficiency. Even small deviations in concentration can reduce emission control performance or damage vehicle components, making precision engineering essential.

Why AdBlue® Dissolving Systems Are Essential for SCR Technology

SCR systems rely on a precise chemical reaction between AdBlue® and exhaust gases. This reaction converts harmful NOx emissions into harmless nitrogen and water vapor. Without a stable and high-quality AdBlue® supply, SCR systems cannot function effectively. A well-designed AdBlue® production system ensures stable AdBlue® quality by maintaining exact concentration and purity levels. It prevents urea crystallization, which can clog injectors and damage SCR components.

By producing AdBlue® on-site, companies also gain full control over quality assurance processes. Additionally, an industrial AdBlue® production system improves overall SCR efficiency by delivering consistent fluid properties under all operating conditions. This leads to measurable reductions in NOx emissions and helps organizations meet both local and international environmental regulations.

Industrial Advantages of AdBlue® Dissolving Systems

The transition from externally supplied AdBlue® to an in-house AdBlue® production system offers multiple industrial advantages. Beyond regulatory compliance, these systems support operational resilience, scalability, and long-term cost optimization.

An industrial-grade AdBlue® production system is designed for continuous operation, making it suitable for high-demand environments such as fleet depots, power plants, and large maintenance facilities. By eliminating dependency on third-party suppliers, businesses reduce exposure to price fluctuations and supply interruptions.

Automation and Process Control

Modern AdBlue® dissolving systems integrate advanced automation technologies to ensure repeatable and error-free production. Automated dosing, temperature regulation, and mixing cycles are standard features of a high-quality AdBlue® production system. Process control units monitor every parameter in real time, allowing operators to detect deviations before they impact product quality. This level of automation not only improves consistency but also reduces labor requirements and human error.

A fully automated AdBlue® production system can be seamlessly integrated into existing industrial control infrastructures, supporting remote monitoring, data logging, and predictive maintenance strategies.

Cost Efficiency and Operational Reliability

From a financial perspective, producing AdBlue® internally delivers significant cost advantages over long-term procurement. Bulk urea sourcing combined with an efficient AdBlue® production system lowers per-liter production costs and stabilizes operating expenses. Operational reliability is another key benefit.

On-site production eliminates delays caused by logistics issues or supplier shortages. For fleet operators and industrial plants, uninterrupted access to AdBlue® is critical to maintaining uptime and avoiding regulatory penalties. By investing in a durable AdBlue® production system, organizations also reduce waste, optimize resource usage, and extend the service life of SCR components.

Applications of AdBlue® Dissolving Systems

AdBlue® dissolving systems are used across a wide range of industries where diesel engines and SCR technology are present. The flexibility of a modular AdBlue® production system allows it to be tailored to different production volumes and operational requirements. From transportation to energy generation, these systems support emission compliance in diverse and demanding environments.

Industries Using AdBlue®Dissolving Systems

Heavy-duty vehicle fleets rely on a dependable AdBlue® production system to support daily operations without interruption. Logistics and transportation companies benefit from centralized AdBlue® manufacturing at depots, reducing refueling downtime. Industrial maintenance facilities use AdBlue® dissolving systems to service equipment and vehicles internally, maintaining quality control.

Power generation plants with diesel-based backup systems also depend on an AdBlue® production system to meet emission limits during operation.In all these sectors, the ability to scale production according to demand makes the AdBlue® production system a strategic asset rather than a simple auxiliary installation.

Why Choose Atmosfer Makina AdBlue® Dissolving Systems?

Selecting the right technology partner is critical when investing in an AdBlue® production system. System design quality, component selection, and after-sales support directly influence long-term performance and return on investment. Atmosfer Makina focuses on engineering-driven solutions that meet industrial performance expectations while remaining flexible and user-friendly. Each AdBlue® production system is designed with efficiency, durability, and compliance in mind.

Custom Engineering and Industrial Quality

Atmosfer Makina develops high-efficiency AdBlue® dissolving systems tailored to specific operational needs. Whether for small-scale fleet operations or large industrial facilities, each AdBlue® production system is engineered to deliver consistent output with minimal maintenance. Industrial-grade materials, corrosion-resistant components, and robust automation architectures ensure long service life even under continuous operation. By prioritizing quality and system integrity, Atmosfer Makina helps clients achieve reliable AdBlue® production with predictable operating costs. A professionally engineered AdBlue® production system is not just a compliance tool—it is a long-term investment in operational efficiency, environmental responsibility, and industrial sustainability.