DEF vs. AdBlue: What Are the Technical Requirements for Production Machinery?

As global emission regulations tighten, Diesel Exhaust Fluid (DEF) and AdBlue have become essential components in reducing nitrogen oxide (NOx) emissions from diesel engines. While the terms are often used interchangeably, there are subtle differences between them, especially in terms of branding and compliance. However, when it comes to the technical requirements for production machinery, precision and standardization remain universally critical.

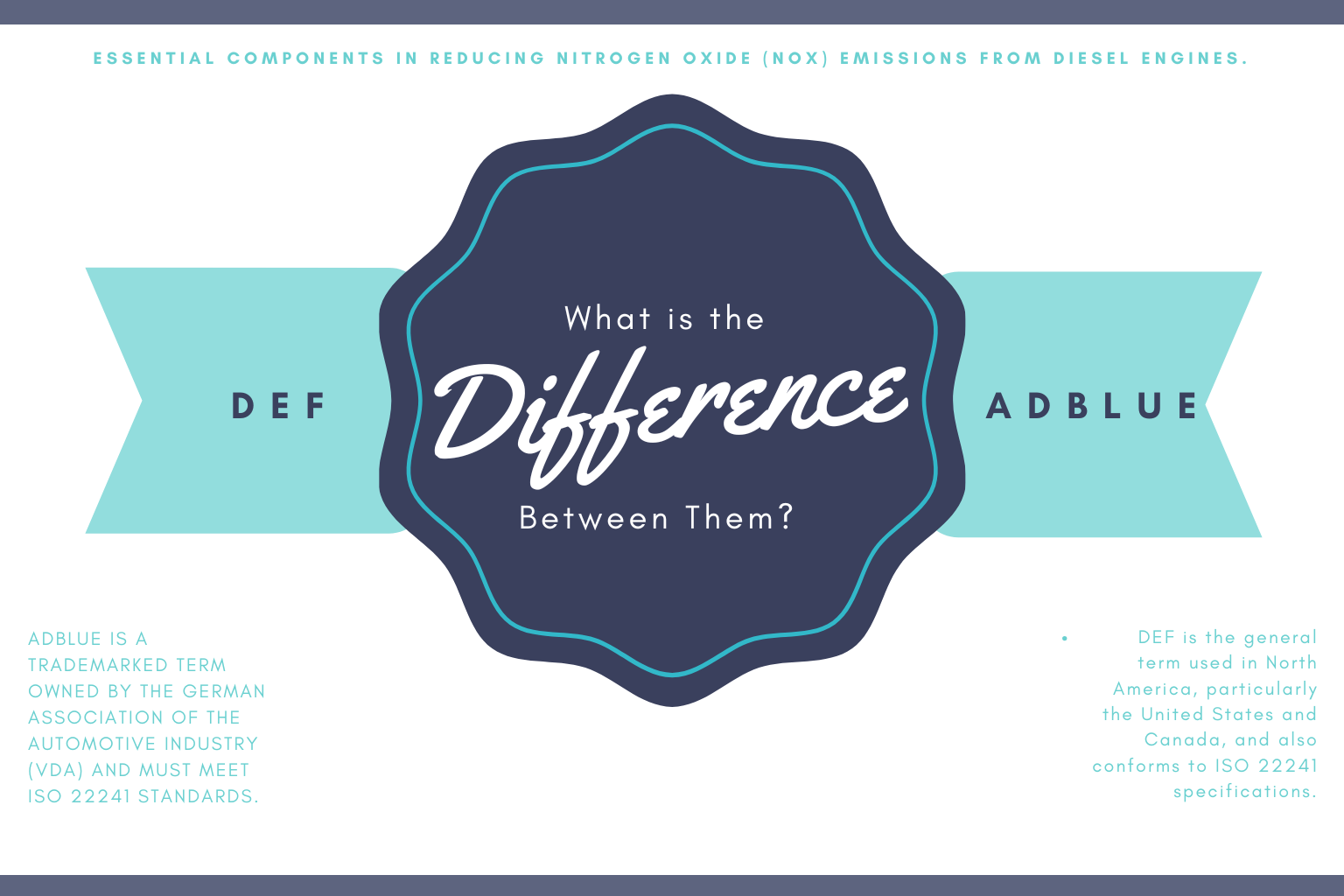

Understanding the Difference Between DEF and AdBlue

At their core, both DEF and AdBlue are composed of a 32.5% high-purity urea solution in 67.5% deionized water. The key distinction lies in regional branding and certification:

- AdBlue is a trademarked term owned by the German Association of the Automotive Industry (VDA) and must meet ISO 22241 standards.

- DEF is the general term used in North America, particularly the United States and Canada, and also conforms to ISO 22241 specifications.

So, from a chemical and functional standpoint, there is no difference between AdBlue and DEF. However, only products certified under the AdBlue license can legally carry the AdBlue name.

Technical Requirements for Production Machinery

Whether producing AdBlue or DEF, machinery must be specifically designed to maintain the purity and composition required by ISO 22241. Below are the key technical requirements:

- Urea Quality and Storage

- Use only automotive-grade urea with very low biuret and heavy metal content.

- Urea should be stored in closed, climate-controlled tanks to prevent contamination and moisture absorption.

- Equipment should include urea feeding pumps made from non-reactive materials (e.g., stainless steel or high-density polyethylene).

- Water Purification System

- Water must be demineralized to remove any ions, salts, or metals.

- Recommended purification methods include:

- Reverse Osmosis (RO)

- Ion Exchange Resins

- UV Sterilization (optional)

- Conductivity of the purified water should be below 0.5 µS/cm to comply with ISO standards.

- Blending Unit

- Accurate mixing is critical. Machinery should maintain a 32.5% urea to 67.5% water ratio with less than ±0.2% deviation.

- Use flow meters, conductivity sensors, and temperature controllers to monitor and adjust the blending process in real time.

- Blending tanks must be non-corrosive, ideally made of polypropylene or stainless steel.

- Automation and Smart Controls

- Modern DEF/AdBlue production lines should feature PLC (Programmable Logic Controller) systems for automation.

- Integration with IoT sensors and remote monitoring enables predictive maintenance and real-time quality assurance.

- Software should support data logging, batch tracking, and compliance reporting for audits.

- Filling and Packaging Equipment

- Filling systems must prevent contamination and maintain sterility throughout the process.

- Bottling machines, IBC (Intermediate Bulk Container) fillers, and tanker loaders should use closed-loop systems.

- Accurate volume control is essential to reduce waste and meet customer specifications.

- Material Compatibility

- All piping, valves, pumps, and tanks must be constructed from AdBlue/DEF-compatible materials.

- Avoid copper, brass, aluminum, and mild steel as they may react with the fluid and compromise its purity.

Trusted Equipment Providers: Atmosfer Makina

For companies seeking robust, compliant, and automated production solutions, Atmosfer Makina offers state-of-the-art DEF/AdBlue manufacturing systems. Their machines are designed specifically to meet ISO 22241 requirements, support remote access, and minimize human error in blending and bottling processes.

For detailed technical consultation or to request a quote, you can contact Atmosfer Makina via:

- Mobile / WhatsApp:

+90 541 947 0414

+90 539 549 05 12 - Email:

General inquiries: [email protected]

Marketing & partnerships: [email protected]

Technical support: [email protected]

Why Purity Matters: The Impact of Contaminants on SCR Systems

In DEF/AdBlue production, even microscopic impurities can have serious consequences. Contaminated fluid can clog injectors, damage the catalyst in Selective Catalytic Reduction (SCR) systems, and trigger vehicle fault codes. As a result, maintaining ultra-high purity is not optional—it’s essential.

Production machinery must be designed to minimize contact with air, metals, and non-compatible materials. Additionally, regular cleaning protocols, closed-loop piping, and sterile filling equipment are all part of maintaining product integrity. Investing in precision equipment saves costs in warranty claims and protects your brand reputation.

Batch vs. Continuous Production: Which Method Is Better for You?

Choosing between batch and continuous production setups depends largely on your output volume, budget, and operational flexibility.

- Batch Production: Ideal for small to medium-scale operations. Easier to manage and allows frequent formula checks. Less initial investment.

- Continuous Production: Suitable for high-demand environments. Offers greater efficiency, consistency, and automation potential, but requires more advanced infrastructure.

Companies like Atmosfer Makina offer scalable systems that can accommodate both models, making it easier to grow as your business expands.

Maintaining ISO 22241 Compliance: Equipment Checklist

To legally sell AdBlue or DEF under recognized standards, producers must comply with ISO 22241. Here’s a simplified checklist your equipment should meet:

- ✅ Demineralized water purification unit (RO or ion exchange)

- ✅ Corrosion-resistant tanks and piping (HDPE, stainless steel)

- ✅ Precision dosing system to maintain 32.5% urea concentration

- ✅ Flow meters, conductivity sensors, and temperature controllers

- ✅ Cleanroom-grade filling and packaging systems

- ✅ Secure storage with temperature control and UV protection

- ✅ Digital batch tracking and compliance reporting tools

Failing to meet these standards may result in product rejection or regulatory penalties.

Common Mistakes in DEF/AdBlue Production and How to Avoid Them

- Using tap water or semi-purified water – This increases mineral content and conductivity, leading to ISO non-compliance.

- Inadequate blending control – Manual mixing often results in improper ratios and poor product quality.

- Incorrect material selection – Using aluminum or copper in piping systems leads to contamination.

- Poor sealing during packaging – Open systems allow air and particles to enter, ruining batch purity.

- No data logging or batch documentation – Failing to track quality can result in liability during audits or customer complaints.

Avoiding these mistakes is easier with modern, automated machinery. Atmosfer Makina’s systems are designed to address each of these issues proactively.

Cost Optimization: How Automation Lowers Operational Expenses

Though automation may seem like a major upfront investment, it significantly reduces operational costs over time by:

- 🔧 Minimizing labor through smart control panels and remote monitoring

- 🕒 Reducing downtime thanks to predictive maintenance alerts

- 📉 Preventing overuse of raw materials via precision metering

- ✅ Ensuring consistent product quality, avoiding reworks or recalls

- 📊 Enabling real-time reporting for easier audits and regulatory checks

This translates to higher profit margins, better scalability, and lower risk exposure. For example, Atmosfer Makina’s automated DEF production units integrate smart diagnostics that notify operators before a fault escalates, saving time and money.

The production of DEF and AdBlue may seem straightforward on the surface, but behind the scenes lies a highly technical and quality-sensitive process. From water purification to blending, packaging, and compliance tracking, every step requires specialized machinery and strict adherence to international standards.

Choosing the right production system isn’t just a technical decision—it’s a strategic one. Whether you’re a new entrant or an established manufacturer seeking to scale up, investing in compliant, automated, and efficient equipment ensures both profitability and long-term success.

If you’re ready to future-proof your DEF or AdBlue operations, connect with Atmosfer Makina to explore turnkey systems built to meet the highest global standards:

- 📞 WhatsApp / Mobile: +90 541 947 0414 or +90 539 549 05 12

- 📧 Email: [email protected] | [email protected] | [email protected]