Who Are Diesel Exhaust Fluid Manufacturers?

Diesel exhaust fluid manufacturers are companies dedicated to producing DEF, a solution vital for reducing emissions in diesel engines equipped with Selective Catalytic Reduction (SCR) systems. These manufacturers play a crucial role in helping businesses meet stringent environmental regulations.

Many of these manufacturers operate a diesel exhaust fluid manufacturing plant, utilizing advanced equipment and processes to ensure the highest quality DEF that adheres to ISO standards.

The Role of a Diesel Exhaust Fluid Manufacturing Plant

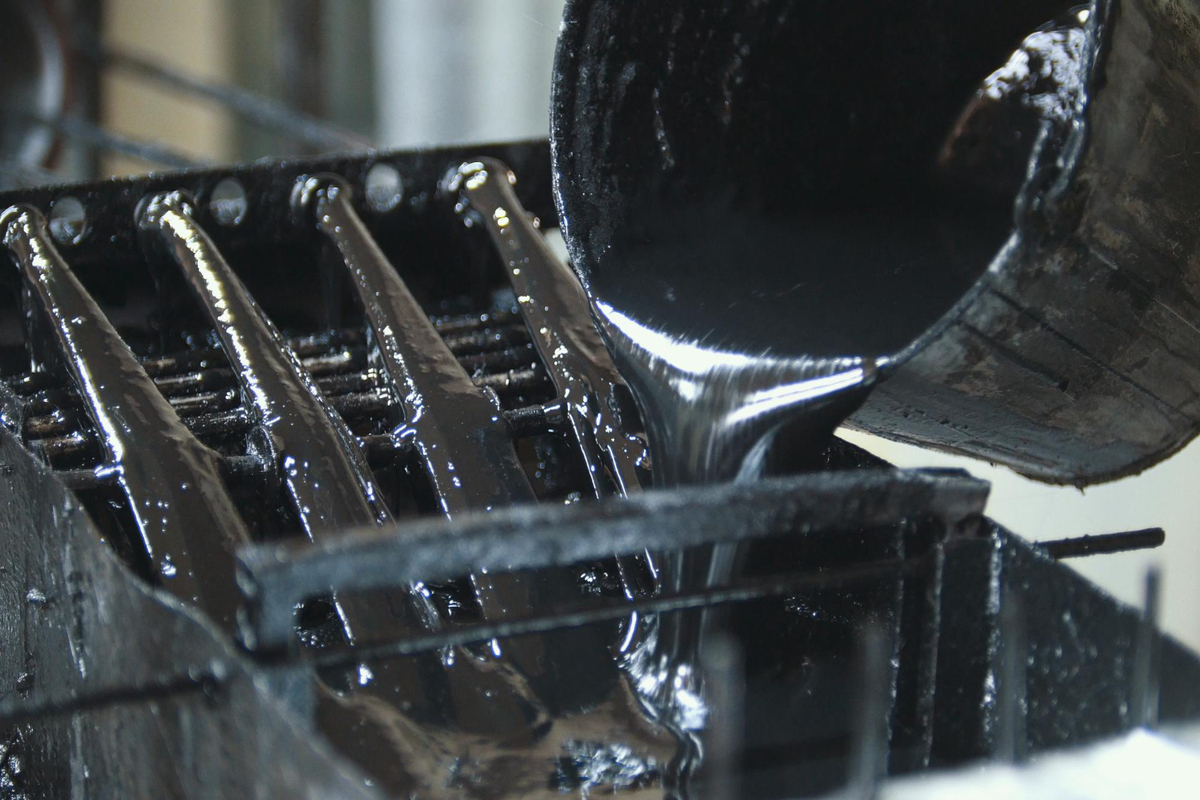

A diesel exhaust fluid manufacturing plant is the backbone of DEF production. It houses specialized equipment, such as mixing tanks and deionized water systems, designed to maintain the purity and consistency of the product. This ensures that the DEF produced meets industry requirements.

Manufacturers rely on these facilities to produce large volumes of DEF efficiently. The use of modern technology within these plants allows for precise blending and rigorous quality control, ensuring the product’s reliability.

How Manufacturers Ensure Quality Control

Maintaining high standards is a priority for diesel exhaust fluid manufacturers. Regular testing of urea concentration and water purity is performed to guarantee compliance with ISO 22241 standards. Advanced monitoring systems within the diesel exhaust fluid manufacturing plant aid in this process.

Manufacturers often invest in state-of-the-art equipment to minimize errors and contamination during production. This commitment to quality builds trust with customers and ensures the DEF is safe and effective for use in SCR systems.

Environmental Benefits of Diesel Exhaust Fluid

One of the primary motivations for diesel exhaust fluid manufacturers is the environmental benefit of their product. DEF significantly reduces nitrogen oxide emissions, a major contributor to air pollution. By producing DEF, manufacturers help industries transition to cleaner practices.

The efficiency of a diesel exhaust fluid manufacturing plant further supports sustainability by minimizing waste during production. This aligns with global efforts to reduce environmental impact and promote sustainable development.

Key Challenges Faced by Manufacturers

While the demand for DEF continues to grow, diesel exhaust fluid manufacturers face several challenges. These include fluctuating raw material costs, compliance with ever-changing regulations, and the need for consistent quality assurance. A well-maintained diesel exhaust fluid manufacturing plant helps mitigate these issues.

Additionally, competition in the industry necessitates constant innovation and efficiency improvements. Manufacturers that invest in advanced technology and sustainable practices are better positioned to overcome these challenges.

The Growing Market for Diesel Exhaust Fluid

The market for DEF is expanding rapidly due to increased adoption of SCR systems in diesel vehicles and stricter emission standards. Diesel exhaust fluid manufacturers are capitalizing on this growth by scaling up production and diversifying their product offerings.

Operating a well-equipped diesel exhaust fluid manufacturing plant enables manufacturers to meet the rising demand while maintaining high-quality standards. This growth provides opportunities for both established players and new entrants in the market.

Partnerships with Logistics and Fleet Companies

Diesel exhaust fluid manufacturers often collaborate with logistics and fleet management companies to provide bulk DEF solutions. These partnerships ensure a consistent supply of DEF to industries that rely heavily on diesel-powered vehicles.

By utilizing a diesel exhaust fluid manufacturing plant, manufacturers can customize production to meet the specific needs of their clients. This adaptability strengthens business relationships and enhances customer satisfaction.

Future Trends in Diesel Exhaust Fluid Manufacturing

The future of diesel exhaust fluid manufacturers lies in technological advancements and sustainability. Innovations in production processes and the integration of renewable energy sources in diesel exhaust fluid manufacturing plants are expected to shape the industry.

As emission regulations continue to tighten, the demand for DEF will only grow. Manufacturers that prioritize efficiency, quality, and sustainability will lead the way in this evolving market.

Conclusion

Diesel exhaust fluid manufacturers play a pivotal role in reducing emissions and supporting global sustainability efforts. Operating a state-of-the-art diesel exhaust fluid manufacturing plant enables these companies to meet market demands efficiently while maintaining the highest quality standards. By addressing challenges and embracing innovation, manufacturers are poised to thrive in a growing and competitive industry.

Frequently Asked Questions

- What is a diesel exhaust fluid manufacturing plant?

- A facility that produces DEF by blending deionized water and high-purity urea to meet industry standards.

- Why is DEF important for diesel engines?

- DEF reduces harmful nitrogen oxide emissions, ensuring compliance with environmental regulations.

- How do manufacturers ensure DEF quality?

- Manufacturers perform regular testing and use advanced equipment to maintain ISO-compliant standards.

- What challenges do diesel exhaust fluid manufacturers face?

- Challenges include raw material costs, regulatory compliance, and maintaining consistent quality.

- How does a manufacturing plant support sustainability?

- Modern plants minimize waste and use efficient processes, aligning with sustainability goals.

- Is the demand for DEF expected to grow?

- Yes, the market is expanding due to stricter emission regulations and increased SCR adoption.

- What role do partnerships play in DEF distribution?

- Manufacturers collaborate with logistics companies to ensure a steady supply of DEF to end-users.

- How do manufacturers address rising production costs?

- Investing in efficient technology and optimizing production processes helps control costs.