Introduction to UAN32 Production Equipment

Producing UAN32 efficiently requires specialized equipment to ensure quality, consistency, and cost-effectiveness. The right machinery enhances production processes, minimizes waste, and meets industry standards for liquid fertilizer production. With the growing demand for UAN32, manufacturers must adopt advanced technologies to optimize production and maintain high standards.

Mixing and Blending Systems

Proper mixing is crucial in UAN32 production to achieve a homogenous solution. Advanced blending systems use high-speed agitators and automated dosing to ensure precise composition. Consistent mixing prevents crystallization and sedimentation, which can impact product quality. Additionally, using computer-controlled mixers can enhance precision and reduce human error, ensuring uniformity in every batch.

Filtration and Purification Units

Filtration is an essential step in UAN32 manufacturing to remove impurities that can clog distribution systems. Multi-stage filtration units help eliminate solid particles and contaminants, ensuring a high-purity final product. Some filtration systems include membrane technologies that provide ultra-purification, enhancing the overall efficiency and safety of UAN32.

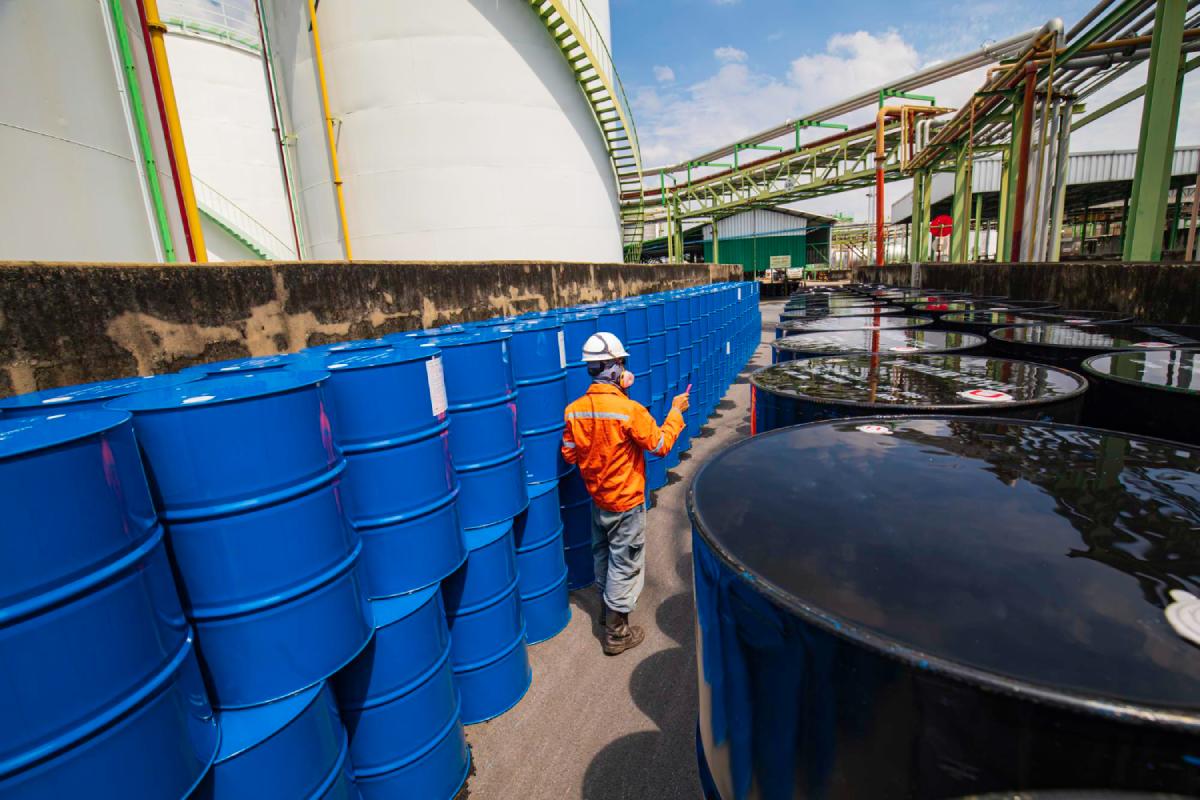

Storage and Handling Equipment

Specialized storage tanks made from corrosion-resistant materials are necessary to store UAN32 safely. These tanks are designed to withstand chemical interactions and prevent contamination. Proper handling equipment, such as transfer pumps and pipelines, ensures smooth product movement within the facility. Automated handling systems can also enhance efficiency by reducing manual labor and ensuring precision in material transport.

Heating and Temperature Control Systems

Temperature control plays a vital role in UAN32 production, as fluctuations can lead to precipitation of salts. Heating systems maintain optimal production conditions, preventing crystallization and ensuring a stable final product. Some facilities implement advanced thermal insulation systems to minimize heat loss, reducing energy consumption and operational costs.

Automation and Process Control

Modern UAN32 production facilities utilize automated systems to monitor and control production variables. Automated dosing, real-time data tracking, and process adjustments help maintain consistency, efficiency, and regulatory compliance. Advanced SCADA (Supervisory Control and Data Acquisition) systems can improve monitoring capabilities, allowing operators to make real-time adjustments and optimize the entire production cycle.

Quality Testing and Compliance Equipment

Quality control is critical in UAN32 manufacturing. Advanced laboratory testing equipment ensures that each batch meets industry standards for nitrogen concentration, purity, and stability. Compliance with regulations guarantees a reliable and effective product. Regular audits and quality assessments help maintain consistent product integrity and prevent deviations that could affect agricultural performance.

Energy-Efficient Production Technologies

With increasing environmental concerns, many UAN32 production plants are adopting energy-efficient technologies. These include waste heat recovery systems, optimized pumping stations, and renewable energy sources to reduce the carbon footprint of fertilizer manufacturing. Investing in sustainability not only enhances operational efficiency but also helps companies meet global environmental regulations.

Safety Measures and Risk Management

Ensuring workplace safety in UAN32 production facilities is paramount. Installing proper ventilation systems, implementing spill containment protocols, and providing workers with protective gear are essential practices. Emergency shutdown systems and real-time monitoring sensors help prevent accidents and ensure a safe working environment.

Conclusion

Essential equipment for UAN32 production includes high-quality mixing systems, filtration units, storage solutions, and automation technologies. Investing in the right machinery enhances efficiency, maintains product integrity, and ensures compliance with agricultural standards. By adopting energy-efficient and safety-focused measures, manufacturers can improve operational sustainability while meeting the increasing demand for UAN32.

FAQ

- What equipment is needed for UAN32 production?

- Essential equipment includes mixing systems, filtration units, storage tanks, and automation technologies.

- Why is mixing important in UAN32 production?

- Proper mixing ensures a uniform solution, preventing crystallization and improving product stability.

- How does filtration improve UAN32 quality?

- Filtration removes impurities, ensuring a high-purity product that meets industry standards.

- What storage conditions are ideal for UAN32?

- Corrosion-resistant tanks and controlled temperatures prevent degradation and contamination.

- How does automation enhance UAN32 production?

- Automated systems ensure precise mixing, real-time monitoring, and compliance with regulations.

- Why is temperature control necessary in UAN32 production?

- Maintaining optimal temperatures prevents precipitation and ensures a stable final product.

- What role does quality testing play in UAN32 manufacturing?

- Testing ensures that UAN32 meets nitrogen concentration and purity standards.

- How does proper handling equipment impact UAN32 production?

- Efficient pumps and pipelines prevent spills, contamination, and product loss.

- Can UAN32 production be optimized for energy efficiency?

- Yes, by using energy-efficient heating and automation systems, manufacturers can reduce costs.

- What are the main challenges in UAN32 production?

- Challenges include maintaining chemical balance, preventing impurities, and ensuring regulatory compliance.