Understanding the Basics of DEF

Diesel exhaust fluid (DEF) is a non-toxic solution composed of high-purity urea and deionized water. It is essential for reducing harmful nitrogen oxide emissions in diesel engines equipped with Selective Catalytic Reduction (SCR) systems. Creating DEF requires precision and adherence to ISO standards.

Whether you’re managing a fleet or setting up a diesel exhaust fluid manufacturing plant, understanding the composition and function of DEF is the first step toward producing a high-quality product.

Why Make Your Own DEF?

Producing DEF in-house offers several advantages, including cost savings and control over quality. By establishing a dedicated diesel exhaust fluid manufacturing plant, you can reduce dependency on suppliers and ensure a consistent supply of DEF for your operations.

Additionally, making your own DEF allows for customization and scalability, enabling businesses to meet specific needs and adjust production according to demand.

Key Materials Needed for DEF Production

The primary ingredients for DEF are high-purity urea and deionized water. These components must meet strict quality requirements to ensure the final product adheres to ISO 22241 standards. A reliable source of both materials is critical for efficient production.

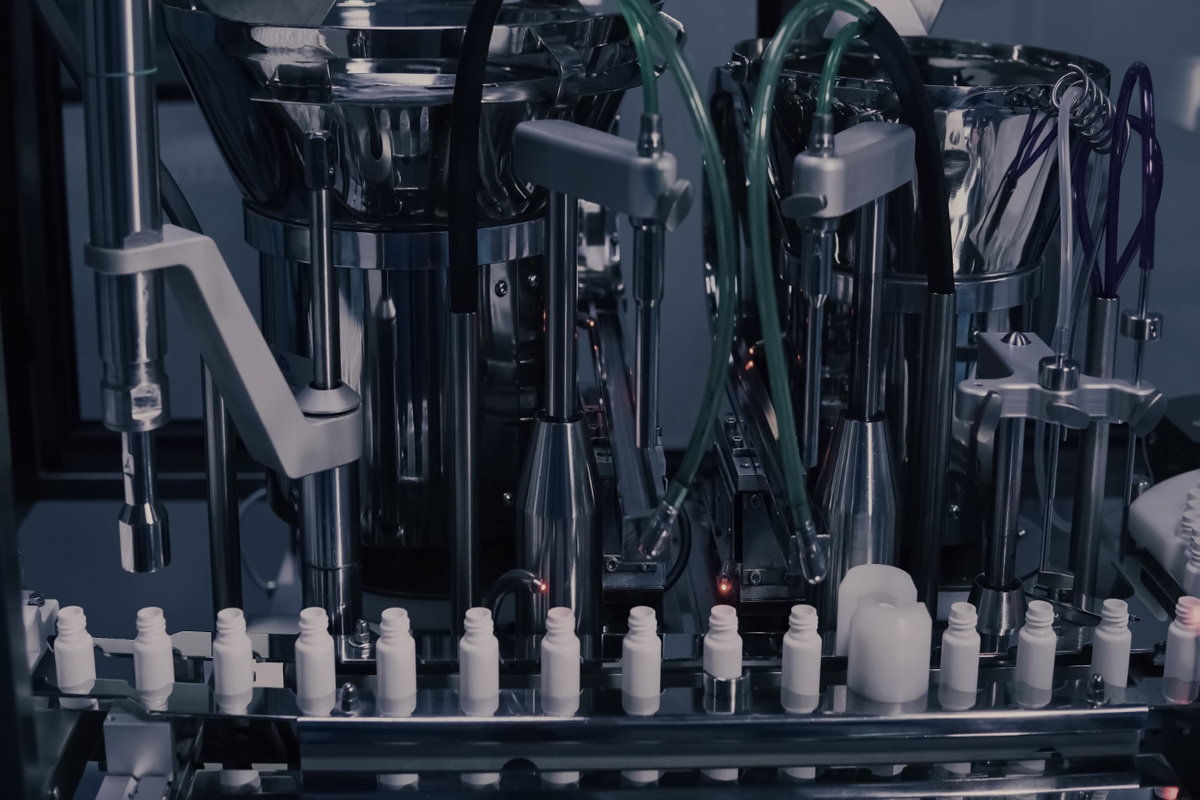

In a diesel exhaust fluid manufacturing plant, equipment such as mixing tanks and deionized water systems are used to combine these materials with precision. This setup minimizes contamination and maintains product consistency.

Essential Equipment for DEF Production

Setting up a DEF production system requires specialized equipment. A diesel exhaust fluid manufacturing plant typically includes a urea blending system, deionized water supply, and quality control mechanisms. Advanced monitoring tools ensure the correct concentration of urea in the final product.

Investing in high-quality equipment not only improves production efficiency but also ensures the DEF produced meets regulatory standards, protecting diesel engines from potential damage.

The Step-by-Step DEF Production Process

The DEF production process begins with sourcing and preparing the raw materials. High-purity urea is dissolved in deionized water to create the DEF solution. Precision is crucial during this stage to achieve the required 32.5% urea concentration.

In a diesel exhaust fluid manufacturing plant, automated systems handle the mixing and blending process, ensuring consistency and accuracy. After blending, the DEF undergoes testing to confirm compliance with ISO standards before being packaged for use.

Quality Assurance in DEF Production

Maintaining quality is paramount when producing DEF. Regular testing of urea concentration and water purity ensures the product meets industry standards. Advanced monitoring tools in a diesel exhaust fluid manufacturing plant simplify this process.

Consistent quality assurance not only protects the reputation of your business but also prevents potential damage to SCR systems, which can result from using substandard DEF.

Packaging and Storage Tips for DEF

Proper packaging and storage are essential for preserving the integrity of DEF. Use airtight containers and clearly label them to prevent contamination. A diesel exhaust fluid manufacturing plant often includes automated filling systems to streamline this process.

Store DEF in a cool, dry environment away from direct sunlight and extreme temperatures. These precautions prevent the degradation of the solution and maintain its effectiveness.

Benefits of In-House DEF Production

Making your own DEF provides businesses with cost efficiency, quality control, and flexibility. A well-equipped diesel exhaust fluid manufacturing plant allows for seamless production and ensures a steady supply of high-quality DEF.

Additionally, in-house production supports sustainability by reducing transportation-related emissions and waste. This aligns with corporate social responsibility goals and enhances your business’s environmental reputation.

Conclusion

Producing your own DEF is a strategic investment that offers numerous benefits, from cost savings to environmental sustainability. Setting up a diesel exhaust fluid manufacturing plant ensures precise and reliable production, meeting the needs of modern diesel engines while complying with regulatory standards. By following the steps outlined in this guide, businesses can establish a successful DEF production process and support their operational goals.

Frequently Asked Questions

- What is diesel exhaust fluid (DEF)?

- DEF is a solution of high-purity urea and deionized water used to reduce nitrogen oxide emissions in diesel engines.

- Why should I produce DEF in-house?

- In-house production offers cost savings, quality control, and scalability for businesses managing diesel fleets.

- What equipment is required to make DEF?

- You need a blending system, deionized water supply, and quality control tools to set up a diesel exhaust fluid manufacturing plant.

- How do I ensure the quality of my DEF?

- Regular testing of urea concentration and water purity ensures the DEF meets ISO 22241 standards.

- What are the key storage requirements for DEF?

- Store DEF in a cool, dry place, away from direct sunlight and extreme temperatures, to maintain its integrity.

- Is DEF production environmentally friendly?

- Yes, DEF reduces emissions and minimizes transportation-related waste, supporting sustainability goals.

- Can I scale up my DEF production?

- Yes, a diesel exhaust fluid manufacturing plant allows for scalable production to meet growing demand.