Why Consider Making Your Own DEF Fluid?

For companies relying on diesel-powered vehicles, the ability to make your own DEF fluid offers significant advantages. DEF, or Diesel Exhaust Fluid, is essential for reducing harmful nitrogen oxide emissions and complying with environmental regulations.

Establishing an in-house DEF production system helps businesses cut costs, maintain a steady supply, and ensure product quality. These benefits make the decision to make your own DEF fluid a strategic move for long-term sustainability.

Key Benefits of Producing DEF In-House

Choosing to make your own DEF fluid allows companies to save on purchasing and logistics costs. Outsourcing DEF can become expensive due to fluctuating supplier prices and transportation fees. Producing DEF internally eliminates these variables.

Additionally, having control over production ensures the DEF meets ISO standards, protecting diesel engines from potential damage. This control enhances reliability and builds trust with fleet operators who rely on the product.

Essential Equipment for DEF Production

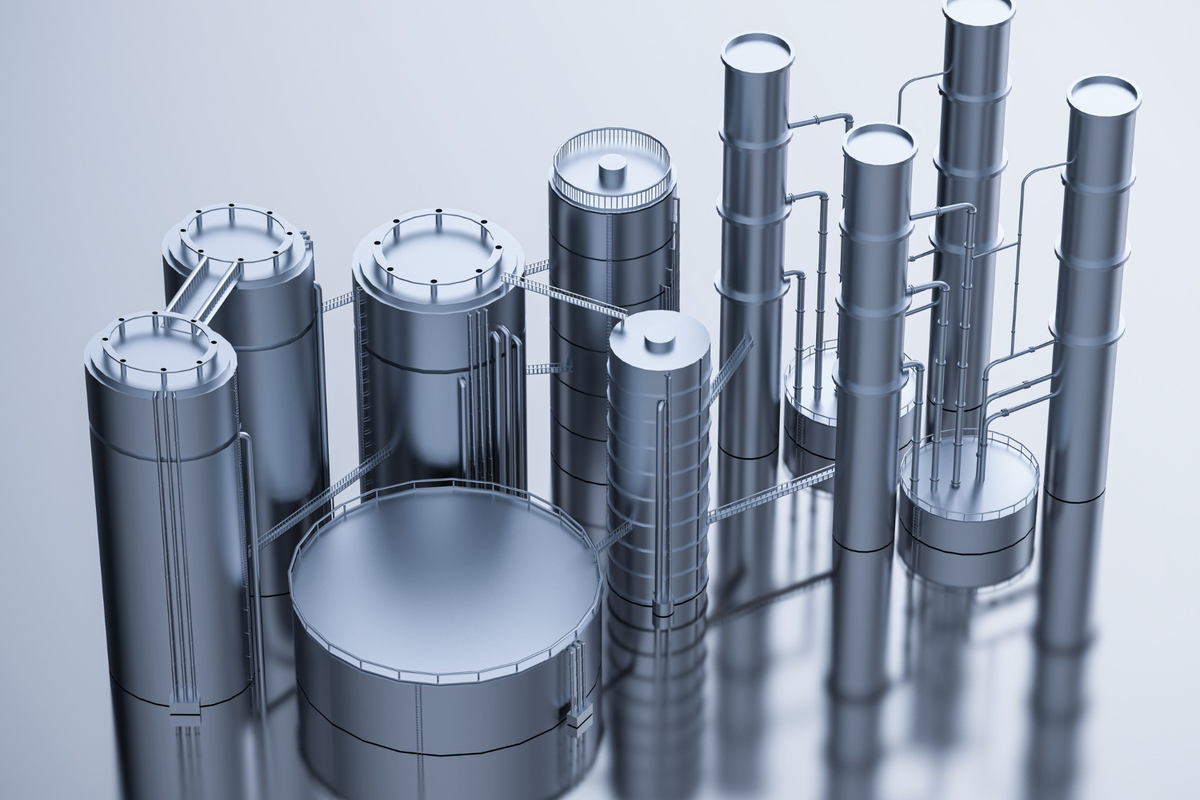

Setting up a DEF production system requires specialized equipment. Key components include mixing tanks, deionized water systems, and automated blending machines. These tools ensure precise mixing of urea and water to produce high-quality DEF.

For businesses planning to make your own DEF fluid, investing in advanced technology improves efficiency and reduces waste, resulting in cost-effective operations.

How to Source High-Quality Materials

To make your own DEF fluid, sourcing high-purity urea and deionized water is critical. These raw materials determine the quality and effectiveness of the final product. Partnering with reputable suppliers ensures consistency and compliance with standards.

Using inferior materials can lead to substandard DEF, which may damage SCR systems and result in costly repairs. High-quality inputs are essential for maintaining product integrity and customer satisfaction.

Steps to Start Your DEF Production

The process to make your own DEF fluid begins with setting up the production site. The facility should have adequate space for equipment, storage tanks, and future expansion. Once the infrastructure is in place, install the necessary machinery and perform initial testing.

During production, high-purity urea is blended with deionized water in precise ratios. Automated systems ensure the DEF meets ISO 22241 standards, making it safe for use in diesel engines. Quality control testing follows to verify the product’s compliance.

Cost Analysis: Saving with In-House Production

One of the primary reasons to make your own DEF fluid is cost efficiency. By producing DEF internally, companies eliminate the need for external suppliers and reduce transportation expenses. This approach can result in significant savings, especially for businesses with large fleets.

Additionally, investing in reliable equipment reduces operational costs over time. A well-maintained system ensures consistent production without unexpected expenses, further enhancing cost-effectiveness.

Environmental Impact of DEF Production

Producing DEF in-house contributes to sustainability efforts by reducing emissions and minimizing transportation-related pollution. Companies that make your own DEF fluid actively participate in creating cleaner air and meeting global environmental goals.

Modern DEF production systems are designed to minimize waste and optimize resource usage, aligning with corporate social responsibility objectives. This commitment to sustainability enhances a company’s reputation in the marketplace.

Scalability for Growing Businesses

For businesses considering how to make your own DEF fluid, scalability is a critical factor. Modular production systems allow for easy expansion as demand grows. This adaptability ensures companies can meet market needs without significant delays.

Planning for future growth during the initial setup of DEF production ensures the business remains competitive and capable of responding to increased demand effectively.

Conclusion

Deciding to make your own DEF fluid offers numerous benefits for businesses, including cost savings, quality control, and environmental sustainability. By investing in the right equipment and sourcing high-quality materials, companies can establish efficient production systems that meet industry standards. In-house DEF production positions businesses for long-term success and enhances their commitment to cleaner emissions.

Frequently Asked Questions

- What is DEF?

- DEF, or Diesel Exhaust Fluid, is a solution made of urea and deionized water used to reduce emissions in diesel engines.

- Why should I make my own DEF fluid?

- Producing DEF in-house offers cost savings, quality control, and a reliable supply for your operations.

- What equipment is needed for DEF production?

- Essential equipment includes mixing tanks, deionized water systems, and automated blending machines.

- How do I ensure my DEF meets standards?

- Regular testing and sourcing high-quality raw materials ensure your DEF complies with ISO 22241 standards.

- What are the cost benefits of in-house DEF production?

- In-house production eliminates supplier and transportation costs, resulting in significant savings.

- Is DEF production environmentally friendly?

- Yes, DEF reduces emissions and helps companies align with sustainability goals.

- Can DEF production systems be scaled?

- Yes, modular systems allow businesses to expand production capacity as demand grows.