What is Diesel Exhaust Fluid (DEF) is a critical component in modern diesel engine technology, designed to reduce harmful emissions and ensure compliance with strict environmental regulations. As emission standards become more demanding across the globe, DEF has evolved from a niche requirement into an everyday necessity for fleet operators, commercial vehicle owners, and even individual diesel car users. DEF, often abbreviated as DEF, is a non-toxic, colorless, and odorless solution used in Selective Catalytic Reduction (SCR) systems. Its primary role is to minimize nitrogen oxide (NOx) emissions produced during diesel combustion. Without DEF, modern diesel engines cannot meet Euro 6, EPA Tier 4, or similar emission standards.

From trucks and buses to agricultural machinery and construction equipment, DEF plays a central role in sustainable transportation. Understanding what DEF is, how it works, and why quality matters can help you protect your engine, reduce operating costs, and stay compliant with regulations. In this comprehensive guide, you will learn everything you need to know about DEF, from its chemical composition to its practical benefits for modern diesel engines.

In the world of modern diesel engines, Diesel Exhaust Fluid (DEF) has evolved from a niche requirement into an everyday necessity. Whether you are a fleet operator, a construction equipment owner, or a diesel car user, understanding DEF is critical for ensuring engine health and remaining compliant with strict environmental regulations like Euro 6 and EPA Tier 4.

The Chemistry of DEF: What is DEF Fluid Made Of?

DEF is composed of a precise and carefully controlled mixture of two simple ingredients: high-purity urea and deionized water. Specifically, DEF consists of 32.5% automotive-grade urea and 67.5% deionized water. This exact ratio is not arbitrary; it is scientifically optimized to ensure efficient chemical reactions within the SCR system. The urea used in DEF is not the same as agricultural fertilizer-grade urea. Automotive-grade urea must meet strict purity standards to prevent contamination, crystallization, or damage to sensitive SCR components. Even small impurities can reduce the effectiveness of DEF and cause long-term harm to the exhaust aftertreatment system. Deionized water is equally important in DEF production.

Minerals, salts, or metals commonly found in tap water can interfere with the chemical stability of Diesel Exhaust Fluid. By using deionized water, manufacturers ensure that Diesel Exhaust Fluid remains stable across a wide range of temperatures and operating conditions. When DEF is injected into the exhaust stream, it undergoes thermal decomposition. The heat converts the urea into ammonia (NH₃), which then reacts with nitrogen oxides inside the SCR catalyst. This reaction transforms harmful NOx gases into harmless nitrogen and water vapor. Because Diesel Exhaust Fluid freezes at approximately -11°C (12°F), vehicles are equipped with DEF tank heaters. Freezing does not damage DEF, and once thawed, it continues to function normally without losing effectiveness.

DEF is a non-toxic, colorless, and odorless solution essential for Selective Catalytic Reduction (SCR) systems. To ensure the chemical stability required for high-performance engines, high-quality DEF follows a precise formula:

- 32.5% Automotive-Grade Urea: Unlike agricultural urea, this is highly purified to prevent crystallization and SCR damage.

- 67.5% Deionized Water: The use of deionized water is crucial because minerals found in tap water can lead to system contamination.

SEO Insight: Highlighting the 32.5% ratio and ISO 22241 standards helps your content rank for technical queries.

How DEF Works in Your SCR System

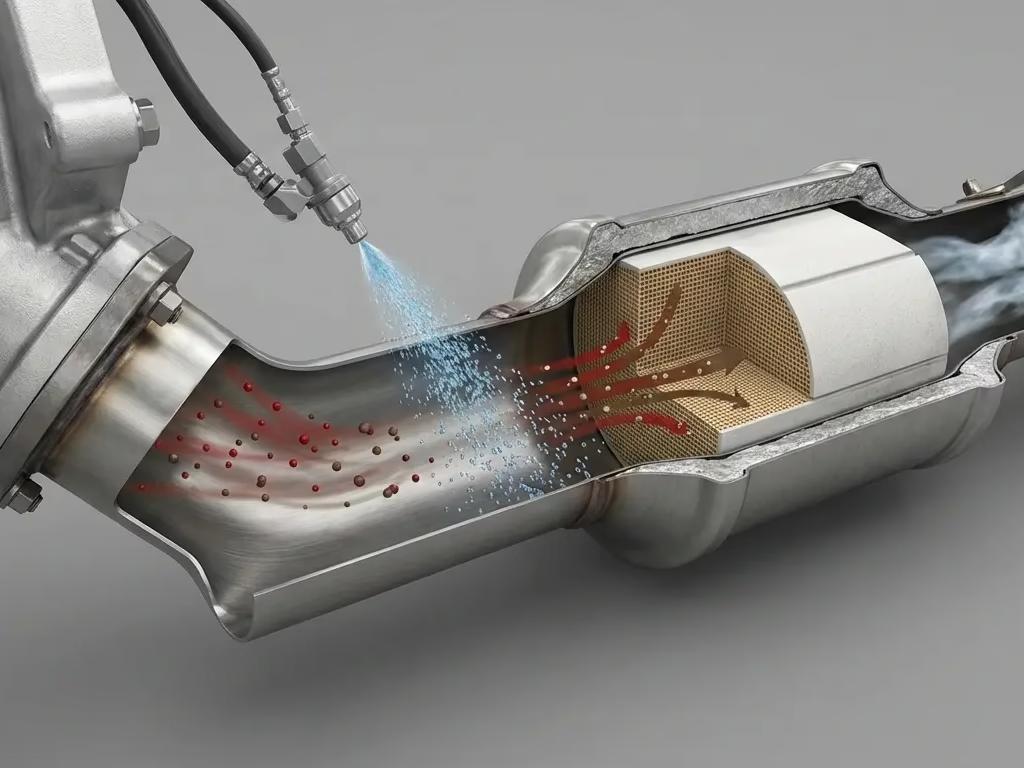

The Selective Catalytic Reduction system is the technological backbone that allows DEF to perform its emission-reducing function. In an SCR-equipped vehicle, Diesel Exhaust Fluid is stored in a dedicated tank separate from diesel fuel. It is never mixed with diesel and should never be added to the fuel tank. As exhaust gases flow through the exhaust system, sensors continuously monitor temperature and NOx levels. Based on this data, the engine control unit calculates the precise amount of DEF required.

The fluid is then injected into the exhaust stream upstream of the SCR catalyst. Inside the SCR catalyst, the ammonia derived from DEF reacts selectively with nitrogen oxides. This selective reaction ensures that NOx emissions are reduced efficiently without affecting other exhaust gases. The end result is a significant reduction in pollutants, often by up to 90%. DEF consumption varies depending on engine size, load, and driving conditions.On average, Diesel Exhaust Fluid usage is approximately 2–5% of diesel fuel consumption. For fleet operators, understanding Diesel Exhaust Fluid consumption patterns helps with cost forecasting and maintenance planning. Modern vehicles are designed to alert drivers when Diesel Exhaust Fluid levels are low. Ignoring these warnings can lead to reduced engine power or even a no-start condition, as emission compliance is mandatory by law in many regions.

The SCR system acts as the technological backbone of your engine’s emission control. Here is the step-by-step process:

- Monitoring: Sensors in the exhaust system track NOx levels and temperature.

- Injection: The engine control unit calculates and injects a precise amount of DEF into the exhaust stream.

- Chemical Reaction: The heat converts DEF into ammonia (NH₃), which reacts with nitrogen oxides inside the catalyst.

- Result: Harmful NOx gases are transformed into harmless nitrogen and water vapor, reducing pollutants by up to 90%.

Why Modern Diesel Engines Require High-Quality Fluid

Not all Diesel Exhaust Fluid is created equal. High-quality DEF must comply with international standards such as ISO 22241. These standards define purity requirements, storage guidelines, and testing methods to ensure consistent performance. Using substandard DEF can result in crystallization, clogged injectors, and damaged SCR catalysts. Repairs to SCR systems can be expensive, often costing far more than the savings gained from purchasing low-quality fluid. For this reason, investing in certified Diesel Exhaust Fluid is a cost-effective decision in the long run. High-quality DEF also ensures accurate dosing within the SCR system.

Consistent chemical composition allows sensors and control units to function correctly, maintaining optimal emission reduction without overuse or underuse of the fluid. Storage and handling also play a vital role in DEF quality. DEF should be stored in sealed containers away from direct sunlight and extreme temperatures. Contamination from dirt, fuel, or other chemicals can compromise Diesel Exhaust Fluid performance and lead to system faults. For businesses operating large diesel fleets, choosing a reliable Diesel Exhaust Fluid supplier ensures consistent quality, regulatory compliance, and operational efficiency. Many manufacturers recommend using branded or certified Diesel Exhaust Fluid to maintain warranty coverage and system reliability.

Not all Diesel Exhaust Fluid is equal. Using substandard fluid can lead to:

- Crystallization and Clogging: Low-purity urea can block injectors and damage catalysts.

- Engine Power Reduction: Modern vehicles are programmed to alert you when DEF is low or of poor quality. Ignoring these can lead to a “no-start” condition or reduced power to enforce legal compliance.

- High Costs: Repairing an SCR system often costs significantly more than the savings from buying cheap, uncertified fluid.

SEO Tip: Always check for ISO 22241 certification on the packaging to ensure the fluid meets international purity standards.

Environmental and Economic Benefits of Diesel Exhaust Fluid

Diesel Exhaust Fluid delivers significant environmental benefits by drastically reducing nitrogen oxide emissions. NOx gases contribute to smog, acid rain, and respiratory health issues. By enabling SCR technology, DEF helps improve air quality in urban and industrial areas. From an economic perspective, Diesel Exhaust Fluid allows diesel engines to operate more efficiently. Because emission control is handled in the exhaust system, engine designers can optimize combustion for performance and fuel economy. This often results in better mileage and lower overall fuel costs. Governments worldwide encourage the use of DEF through emission regulations and compliance programs. Vehicles that fail to meet emission standards may face fines, operational restrictions, or registration limitations.

Beyond meeting legal requirements, DEF offers several advantages:

- Better Fuel Economy: Because emission control happens in the exhaust, designers can optimize the engine for better mileage and performance.

• Cleaner Air: By reducing NOx, DEF helps lower the levels of smog and acid rain, improving respiratory health in urban areas.

Common Myths and Misconceptions About Diesel Exhaust Fluid

One common misconception is that DEF is a fuel additive. In reality, Diesel Exhaust Fluid never comes into contact with diesel fuel. Adding Diesel Exhaust Fluid to the fuel tank can cause severe engine damage. Another myth is that Diesel Exhaust Fluid is hazardous. While it should be handled properly, Diesel Exhaust Fluid is non-toxic and safe to use when stored and applied according to guidelines. Some users also believe that skipping DEF refills will not affect vehicle performance. Modern engines are designed to enforce compliance, and ignoring DEF requirements can result in reduced power or vehicle immobilization.

- Myth: DEF is a fuel additive.

- Fact: DEF must never be added to the fuel tank. It is stored in a separate dedicated tank and injected directly into the exhaust.

- Myth: Freezing ruins DEF.

• Fact: DEF freezes at -11°C (12°F), but once thawed, it functions normally without losing its effectiveness.

Choosing the Right Diesel Exhaust Fluid for Your Vehicle

When selecting DEF, always check for ISO 22241 certification on the packaging. This ensures that the product meets international quality and purity standards. Consider purchasing DEF in sealed containers from reputable suppliers. Bulk DEF solutions are ideal for fleets but require proper storage tanks and dispensing systems to prevent contamination. Regularly inspect DEF tanks, lines, and injectors as part of routine maintenance. Clean systems ensure that DEF performs optimally and extends the lifespan of the SCR system.

Final Thoughts: Why DEF Matters

Diesel Exhaust Fluid is more than just a regulatory requirement; it is a cornerstone of modern diesel engine technology. By enabling effective emission reduction, DEF supports environmental sustainability, regulatory compliance, and engine efficiency. Understanding how DEF works, why quality matters, and how to use it correctly empowers vehicle owners and fleet managers alike. As emission standards continue to evolve, DEF will remain an essential component in the future of clean diesel technology. By choosing high-quality DEF and following best practices, you protect your engine, reduce environmental impact, and ensure smooth, reliable operation for years to come.

Reliable Diesel Exhaust Fluid Solutions by Atmosfer Makina

Meeting modern diesel emission standards requires the right equipment and high-quality Diesel Exhaust Fluid. Atmosfer Makina provides professional, industry-proven solutions tailored to the needs of fleet operators, industrial facilities, and heavy-duty vehicle users who rely on consistent SCR system performance. Atmosfer Makina offers Diesel Exhaust Fluid solutions that are fully compatible with SCR systems and compliant with ISO 22241 standards. Manufactured with high purity, these Diesel Exhaust Fluid products help maintain engine efficiency, reduce crystallization risks, and protect critical SCR components from clogging and premature failure. As a result, businesses benefit from lower maintenance costs and longer system lifespan.

Beyond Diesel Exhaust Fluid supply, Atmosfer Makina delivers end-to-end solutions including DEF storage, transfer, and dosing systems. These integrated solutions are designed to improve operational efficiency, ensure safe handling, and provide uninterrupted supply especially for high-consumption fleets and industrial operations. If you are looking to stay fully compliant with emission regulations, protect your SCR systems, and achieve reliable performance with premium Diesel Exhaust Fluid, Atmosfer Makina is your trusted solution partner. To learn more and discover Diesel Exhaust Fluid solutions tailored to your business, visit Atmosfer Makina and get in touch with the expert team today.