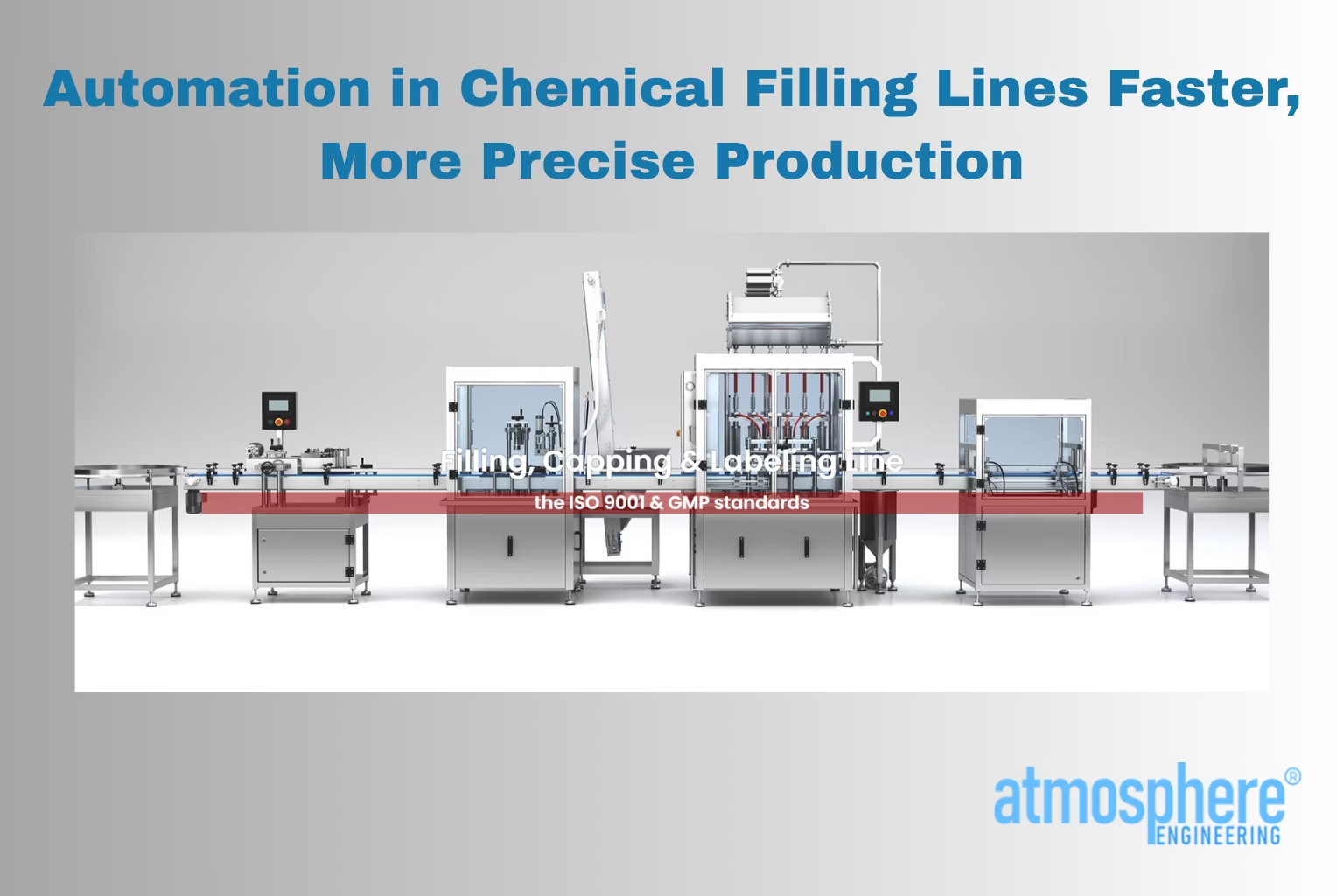

Automation in Chemical Filling Lines: Faster, More Precise Production

Welcome to the future of chemical manufacturing. At Atmosfer Makina, we understand that in the chemical industry, speed is nothing without precision. As a leading manufacturer of high-performance chemical filling machinery and complete packaging line solutions, we’ve seen firsthand how the integration of automation transforms an operation from merely productive to genuinely revolutionary. This transformation is driven by our commitment to engineering excellence, focusing on systems that deliver unparalleled accuracy, speed, and reliability.

The demands on chemical producers are relentless: strict regulatory compliance, increasing product diversity, and the need for cost-efficient scaling. Manual or semi-automatic processes simply can’t keep pace or guarantee the batch-to-batch consistency that defines quality. This is why investing in automated chemical filling lines isn’t just an upgrade; it’s a strategic imperative for long-term success.

We are here to show you how our expertly designed filling and packaging systems—from automatic filling machines to smart control solutions—are setting new standards for chemical production efficiency and quality across the globe.

The Core of Efficiency: Automated Filling and Control Systems

The heart of an optimized chemical production line lies in its automation. By replacing manual processes with precision-engineered machinery, we eliminate the variability and bottlenecks that plague traditional operations.

Automatic Filling and Labelling Systems

In the chemical sector, whether you are dealing with corrosive acids, viscous solvents, or delicate liquid detergents, the filling process is the most critical step for both product integrity and safety. Our automatic filling solutions are designed to handle a vast spectrum of chemical products and container types—from small bottles to large jerrycans and drums—with exceptional speed and repeatability.

Our filling machines utilize advanced technologies such as magnetic flow meters or weight-based filling systems to achieve superior dosing accuracy. This means every single container receives the precise amount of product, drastically reducing the risk of costly overfilling or underfilling. For highly corrosive materials, our systems are built with chemically resistant materials (like specialized stainless steel or PTFE) to ensure maximum durability and operator safety.

But filling is only half the battle. A complete packaging line solution requires seamless integration with automatic labelling machines.

- Precision Label Application: Our automatic label applicators ensure that every label—whether it’s a single front label, a wrap-around, or a multi-panel hazardous goods label—is applied perfectly straight, without wrinkles or bubbles, and in the exact same position on every single unit. This attention to detail is vital for brand consistency and adherence to regulatory standards for chemical packaging.

- Integrated Coding and Marking: Furthermore, our systems incorporate high-speed coding and marking solutions (like inkjet or laser coders) to print essential information like batch codes, expiry dates, and serialization data. This integration is crucial for product traceability and inventory management, forming a key pillar of a modern, compliant production line.

By deploying an integrated automatic filling and labelling system, our clients achieve phenomenal increases in throughput capacity while simultaneously boosting product presentation and regulatory compliance.

The Impact of Smart Control Systems

The true intelligence in our chemical filling lines comes from the smart control systems that power them. These are not merely on/off switches; they are sophisticated, interconnected Industrial IoT (IIoT) platforms that govern the entire packaging process.

Our systems are controlled via intuitive HMI (Human-Machine Interface) touchscreens, giving operators complete, real-time command of the line. Key features of these advanced control systems include:

- Real-Time Monitoring and Diagnostics: Operators can view live data on filling speed, pressure, temperature, and machine status. The system constantly runs predictive diagnostics, alerting teams to potential mechanical or process issues before they lead to downtime. This proactive maintenance approach maximizes operational efficiency and machine lifespan.

- Recipe Management: For businesses handling diverse chemical products (different viscosities, densities, and container sizes), digital recipe management is a game-changer. Operators can switch between different product settings and container formats with a few taps. The smart system automatically adjusts all parameters—fill volume, conveyor speed, capping torque, and label placement—ensuring a rapid product changeover with minimal human error. This feature alone drastically cuts the time and labor associated with format adjustments.

- Data Logging and Reporting: Every action, every fill, and every sensor reading is recorded. This detailed data logging provides a comprehensive audit trail critical for regulatory compliance (e.g., ISO, FDA, REACH). This data is also invaluable for process optimization, allowing engineers to analyze production trends and continually refine performance for maximum yield and efficiency.

In essence, our smart control systems transform raw machinery into an intelligent, adaptive production asset, ensuring peak performance and providing the data foundation for a truly digital chemical plant.

Beyond Speed: Quality and Sustainability

The benefits of chemical filling automation extend far beyond simple speed. The inherent precision and consistency of automated systems directly address the most significant challenges in the chemical industry: controlling waste and maintaining unblemished product quality across every single batch.

Waste Reduction through Precision

Product waste, or product loss, is one of the most substantial hidden costs in manual and semi-automatic filling operations. Overfilling, spills, container rejections due to inaccurate fills or poor labelling, and lengthy startup/shutdown processes all contribute to significant material loss. Atmosfer Makina’s automated solutions turn this equation on its head.

- Minimizing Overfill: The primary driver of waste is overfilling. Our high-precision filling technology guarantees a fill accuracy that is often superior to the industry standard. By tightening the tolerance on fill volume, we ensure that you are not giving away valuable product in every container. For high-volume production, these fractional savings translate into a massive reduction in raw material consumption and a significant boost to your bottom line.

- Reduced Spillage and Rejects: Automated, synchronized movement of containers, coupled with features like anti-foaming and anti-splash nozzles, virtually eliminates product spillage. Furthermore, the reliable precision of both the filling and automatic labelling process means fewer containers are rejected for incorrect fill levels or misapplied labels, which would otherwise have to be scrapped or reworked.

- Efficient Clean-in-Place (CIP) Systems: Chemical product changeovers often require extensive cleaning. Our machinery is designed for quick and efficient CIP processes, reducing the amount of valuable time and resources (water, cleaning agents) needed for sanitization, further contributing to sustainable manufacturing.

This holistic approach to precision not only cuts waste but also supports your commitment to environmental sustainability, an increasingly important metric for modern chemical businesses.

Quality Consistency and Batch Management

In chemical production, quality consistency is non-negotiable. Whether it’s maintaining the exact concentration of a disinfectant or the precise viscosity of a lubricant, deviation can have severe consequences for product performance, customer satisfaction, and regulatory standing.

Automation is the ultimate tool for achieving consistent quality:

- Repeatable Processes: Automated systems execute the same task—down to the millisecond and microliter—every single time. The digital recipe eliminates the human variability that is the root cause of most inconsistencies. This ensures that the 10,000th unit is identical to the first, a level of production consistency impossible to achieve manually.

- Robust Batch Management and Traceability: Our smart control systems are built to support robust batch management. Every single bottle can be linked back to the exact batch of raw materials used, the time and date of filling, and the specific machine parameters at that moment. Should a quality issue ever arise, this complete traceability allows for a surgical and rapid recall or investigation, protecting your reputation and minimizing liability. This is crucial for regulatory compliance in hazardous or highly-regulated chemical packaging sectors.

- Integrated Quality Checks: Automated systems allow for the seamless integration of in-line quality control sensors. This can include check-weighers to verify fill weight, vision systems to confirm cap presence and label position, and seal verification tools. Any deviation from the set tolerance is instantly flagged, and the defective unit is automatically ejected from the line, ensuring that only perfect products reach the consumer.

By implementing Atmosfer Makina’s advanced automation solutions, you are not just buying a machine; you are securing a future of high-speed production defined by uncompromising quality and unbeatable efficiency. We deliver the packaging machinery that allows you to confidently scale your operations while reducing cost and risk.

Frequently Asked Questions (FAQ)

Here are the most common questions our clients ask about making the transition to chemical filling line automation.

| Question (Customer’s Perspective) | Answer (Atmosfer Makina’s Perspective) |

| “Our products are highly corrosive and dangerous. How can automation ensure the safety of my employees during filling?” | Safety is our top priority. Our automatic chemical filling machines are engineered with specialized, corrosion-resistant materials and a fully enclosed design to minimize operator exposure. Furthermore, we integrate advanced safety features such as robust interlocking guards, emergency stop systems, and sealed filling environments. By removing the operator from direct contact with the hazardous material during the filling process, we significantly enhance workplace safety and regulatory compliance. |

| “We run many different products—from thin liquids to thick gels—and switch formats often. How fast is the changeover on your automated lines?” | Speed and flexibility are built-in. Our automatic filling solutions are designed for quick changeover. With our smart control systems and digital recipe management, switching between product recipes and container formats involves recalling a pre-set program. Mechanical adjustments are minimized, often tool-less, and guided by the HMI. This typically reduces changeover time from hours to mere minutes, ensuring you maintain maximum operational uptime. |

| “Is the initial investment in a fully automated line really worth it, or should we stick to semi-automatic?” | The initial investment is a strategic one that yields significant long-term cost-efficiency. Automation virtually eliminates human error, drastically reduces product waste (via precision filling), lowers labor costs, and enables a level of production scaling that is impossible with semi-automatic machines. The increase in throughput and the savings from reduced waste typically lead to a rapid return on investment (ROI), making it the most cost-effective path for growth. |

| “How can I be sure the machine is filling every container accurately? We can’t afford to overfill expensive chemicals.” | We guarantee unparalleled precision. Our automatic chemical filling systems utilize the most reliable technology for your product, such as high-precision flow meters or load cell-based (gravimetric) filling. These sensors provide real-time fill confirmation, and our smart control system constantly self-calibrates and adjusts, ensuring that every container is filled to the exact tolerance you specify, eliminating costly overfilling. |

| “We need to meet strict regulatory standards for batch traceability. Does the machine help with that?” | Absolutely. Our automated packaging lines are built with full traceability in mind. The integrated smart control system logs every production variable for every batch, including fill volume, date, time, and machine settings. This data, coupled with high-speed coding and marking of batch codes and serial numbers on the package, provides an unbreakable digital audit trail critical for regulatory compliance and secure product recall management. |

Contact Atmosfer Makina

Ready to transform your chemical production with intelligent automation?

The path to faster, more precise, and more profitable chemical manufacturing begins with the right filling and packaging machinery. Contact us today to discuss a tailored solution for your specific needs.

| Category | Details |

| Location | Kızılcaşar MAh. 4200 cad. no:39 Atabilge incek Sitesi c blok d:140 Gölbaşı /Ankara |

| Office Phone | +90 312 504 6460 |

| Mobile / WhatsApp | +90 541 947 0414 |

| +90 539 549 05 12 | |

| General Email | [email protected] |

| Sales Email | [email protected] |

| Technical Support Email | [email protected] |