Zero Waste Strategies in Industrial Production: Protecting Cost and the Environment

Zero Waste Strategies in Industrial Production: Protecting Cost and the Environment Welcome to Atmosfer Makina, where we believe that profitability and sustainability are not just compatible—they are mutually dependent. In today’s competitive global market, the pressure is on industrial manufacturers to be both highly efficient and environmentally responsible. This dual challenge requires more than just minor adjustments; it demands a fundamental shift toward a Zero Waste strategy. As a leader in designing and implementing advanced industrial machinery and complete production line solutions, we have witnessed how embracing waste reduction technologies transforms a factory floor. A Zero Waste approach is no longer a niche environmental movement; it is a powerful business model that directly impacts your bottom line by minimizing material input, optimizing processes, and unlocking hidden value from waste streams. At Atmosfer Makina, our expertise extends beyond simply building reliable machines; we engineer sustainable production systems that integrate resource efficiency into every step, from material handling to final packaging. We invite you to explore how modern industrial waste management and circular economy principles can revolutionize your operations, secure cost savings, and position your company as a leader in sustainable manufacturing. The Foundation of Efficiency: Waste Reduction and Resource Recovery Achieving a Zero Waste manufacturing facility begins with a comprehensive strategy focusing on two key areas: aggressive waste minimization at the source and the implementation of intelligent resource recovery models. Waste Reduction and Recycling Models The core principle of Zero Waste is simple: waste is a resource out of place. The most effective way to manage waste is to prevent it from being generated in the first place. This is where Atmosfer Makina’s precision machinery plays a crucial role. Precision Engineering for Source Reduction: In production lines (especially in filling, packaging, and chemical processes), a significant portion of waste comes from inaccuracies—overfilling, rejected packaging due to misalignment, and product spillage. Our high-accuracy filling machines and integrated quality control systems (like vision inspection and check-weighers) ensure that every unit is filled and packaged perfectly the first time. This source reduction minimizes the use of raw materials and slashes costly disposal fees. Internal Closed-Loop Recycling Systems: For inevitable process by-products, a modern factory must implement closed-loop recycling. This means waste generated in one part of the plant becomes a raw material for another. For example, in liquid processing, residual product in pipes or cleaning water can be recovered, treated (using our specialized filtration or distillation units), and safely re-introduced into the production stream. This material recycling minimizes the need for virgin materials and reduces reliance on external, often costly, waste disposal companies. Optimal Packaging Design and Materials: Beyond the process, we consult on sustainable packaging strategies. This includes advising on machinery capable of handling recycled content packaging (like recycled PET or rHDPE) and minimizing the packaging footprint (e.g., lightweighting or optimizing container shapes). Our labelling and capping machines are calibrated to handle these new eco-friendly materials without compromising line speed or integrity. Waste recycling should start with the package itself. By combining manufacturing precision with smart material flow management, we help clients transform from a linear “take-make-dispose” model to a truly circular manufacturing process. Energy and Heat Recovery Beyond material waste, the other major source of inefficiency in industrial production is energy waste, often lost as heat, compressed air leakage, or inefficient motor usage. Zero Waste extends to maximizing energy efficiency and implementing heat recovery systems. Optimized Machine Efficiency: All Atmosfer Makina machinery is designed with energy efficiency as a core standard. We utilize high-efficiency motors (IE4) and variable frequency drives (VFDs) on conveyors and pumps. VFDs adjust motor speed based on the real-time load, drastically cutting energy consumption compared to traditional motors that run at a constant, unnecessary maximum speed. This focus on operational energy optimization directly reduces your utility bills and carbon footprint. Industrial Heat Recovery Systems: In many industrial processes—especially those involving drying, sterilization, or chemical reactions—a large amount of heat is generated and typically vented into the atmosphere. This is wasted money. We integrate heat exchangers and thermal energy recovery systems that capture this waste heat. This captured energy can then be used to pre-heat boiler feed water, warm up process chemicals, or even heat the factory floor in winter. This process efficiency can offset a significant percentage of a facility’s heating energy needs, leading to monumental cost savings and making your production genuinely sustainable. Smart Monitoring and Control: Our advanced control systems (HMI and SCADA integration) are key to managing energy consumption. They provide real-time data on the energy usage of every component, allowing operators to identify and eliminate energy-wasting bottlenecks or non-productive running periods. This data-driven resource efficiency ensures that every Joule is used optimally. Implementing these energy management and waste minimization strategies moves a facility far beyond simple compliance and into the realm of economic and environmental leadership. Zero Waste in Practice: Optimization and Innovation The ultimate goal of a Zero Waste strategy is to integrate sustainability into the fabric of the manufacturing plant, turning philosophical commitments into concrete, measurable actions. This requires moving from concepts to specific, replicable production examples and optimizing every phase of resource use. Real-World Zero Waste Production Examples The theory of industrial sustainability comes alive when applied to specific industry challenges. Atmosfer Makina has supported clients in diverse sectors to achieve measurable Zero Waste success: Chemical & Detergent Production: Chemical processing often leaves residual product in tanks and lines. We implement pigging systems and specialized product recovery machinery that pushes virtually all of the high-value chemical out of the pipe before cleaning, maximizing yield and minimizing the amount of contaminated wastewater that requires costly treatment. This turns potential hazardous waste into valuable saleable product. Beverage and Food Processing: In bottling operations, rejected bottles (due to minor imperfections or filling errors) are common. Our systems use advanced sorting and de-capping mechanisms to automatically recover the liquid product from the rejected containers, which is then filtered and re-introduced into the batch, while the packaging material (glass, plastic, aluminum) is sorted for high-grade

Industrial Water Purification Systems: A Comprehensive Guide

Industrial Water Purification Systems: A Comprehensive Guide At Atmosfer Makina, we know that water is far more than a utility—it’s the lifeblood of modern industry. Whether you’re operating a power plant, a food processing facility, or a chemical production line, water quality plays a pivotal role in everything from product safety to system longevity. As experts in water purification, we design and deliver custom reverse osmosis (RO) systems tailored to the rigorous demands of industrial operations. In this guide, we’ll walk you through the key technologies, target industries, system components, and our turnkey project approach. Types of Water Purification Technologies (RO, UF, EDI) Water purification is not a one-size-fits-all process. Depending on your industry and water source, your system may require different levels of filtration and demineralization. At Atmosfer Makina, we offer advanced water purification solutions based primarily on Reverse Osmosis (RO), but we also integrate Ultrafiltration (UF) and Electrodeionization (EDI) technologies where needed. Reverse Osmosis (RO) RO is the backbone of industrial water purification. It works by applying pressure to push water through a semi-permeable membrane that removes up to 99% of dissolved salts, bacteria, viruses, and other contaminants. This method is ideal for industries requiring consistently high-quality water such as energy, pharmaceuticals, and manufacturing. We offer several RO models under our premium lines: ELITE Series – Designed for seawater desalination applications. PLATINUM Series – Optimized for high-volume, land-based facilities. OCEAN Series – Engineered for compact marine and mobile systems. Ultrafiltration (UF) UF is often used as a pre-treatment step before RO, especially when the raw water contains large particles or biological contaminants. It removes suspended solids, colloids, and some bacteria, thereby extending the life of downstream RO membranes. Electrodeionization (EDI) EDI is used post-RO to achieve ultrapure water levels without chemicals. It uses ion exchange membranes and electrical current to continuously deionize water. This is ideal for high-purity applications like electronics manufacturing or boiler feedwater in power plants. Which Industries Use Advanced Water Treatment Systems? Industries across the board depend on clean, consistent water. Here are the sectors we serve with our industrial-grade purification systems: Energy & Power Generation Boilers and turbines require water that is free of minerals and ions to prevent corrosion and scaling. Our RO and EDI systems produce ultra-clean water that protects your infrastructure and boosts thermal efficiency. Pharmaceutical & Biotech In these sectors, compliance with USP and EP standards is critical. Our systems ensure water is pure enough for injections, ingredient formulation, and sterile cleaning. Food & Beverage From bottled water to dairy processing, water impacts taste, safety, and product consistency. Our systems remove off-flavors, contaminants, and pathogens to meet food-grade quality. Chemical & Petrochemical Our RO solutions support chemical processes that require stable water chemistry, minimizing the risk of contamination or undesired reactions. Electronics & Semiconductor This industry demands ultrapure water (UPW) with resistivity levels up to 18 MΩ·cm. Our RO + EDI systems meet this strict requirement, ensuring clean circuits and high product yield. Marine & Offshore For ships, offshore rigs, and remote units, water purification must be compact, durable, and efficient. Our OCEAN series RO systems deliver reliable desalination under the harshest conditions. Main Components of a High-Efficiency Purification Setup A well-designed purification system is more than just a membrane. It is a coordinated set of components, working seamlessly together. Pre-Treatment Units These units remove large debris, chlorine, and hardness that could damage sensitive RO membranes. They may include: Multimedia filters Activated carbon filters Water softeners High-Pressure Pumps Our systems use robust high-pressure pumps to drive water through RO membranes efficiently. Selecting the right pump ensures optimal energy use and membrane life. Reverse Osmosis Modules The heart of the system. Our RO units feature spiral-wound membranes designed to reject a wide spectrum of dissolved impurities, from salts to organic materials. Ultrafiltration Modules (optional) When required, UF modules are used upstream of RO to remove bacteria, algae, and suspended solids. Electrodeionization Units (optional) For industries that need chemical-free, ultrapure water, we integrate EDI after RO. This setup allows continuous operation and low maintenance. PLC-Controlled Automation Systems Every Atmosfer Makina system includes a user-friendly control panel equipped with: Real-time conductivity, flow, and pH monitoring Fault alerts Auto start/stop and CIP functions Skid-Mounted Compact Design Our systems are delivered ready-to-install, minimizing onsite work. Each unit is factory-tested and built with space efficiency in mind. Turnkey Projects by Atmosfer Makina Our expertise goes beyond components. We offer complete turnkey water purification projects, tailored to your unique needs. Step 1: Consultation & Water Analysis We assess your raw water quality, operating environment, and industry standards. Based on this, we select and size every component of your system. Step 2: Custom Engineering We design and model your purification setup using advanced simulation tools. All components are carefully selected for maximum durability and compatibility. Step 3: Manufacturing & Testing Your system is built in our facility and undergoes rigorous quality control testing before shipment. Step 4: Installation & Commissioning Our technicians install the system on your site, integrate it with existing utilities, and ensure it’s fully operational from day one. Step 5: Training & After-Sales Support We train your staff to operate and maintain the system. Our support team is always available for technical assistance and spare parts. Frequently Asked Questions (FAQ) How does reverse osmosis actually work in industrial settings? ➡️ RO uses pressure to force water through a membrane, filtering out salts, minerals, and microbes. The result is purified water suitable for industrial applications. What industries benefit the most from Atmosfer Makina’s RO systems? ➡️ Energy, pharma, F&B, chemicals, electronics, and marine industries all benefit significantly from our high-efficiency RO setups. Do you offer systems for seawater desalination? ➡️ Yes. Our ELITE and OCEAN series are designed specifically for seawater and high-salinity sources. Can I use your RO system in a pharmaceutical-grade process? ➡️ Absolutely. We comply with USP and EP water quality standards and offer systems compatible with sterile environments. What is the lifespan of your RO membranes? ➡️ With proper pre-treatment and

AdBlue® Production Line – AUS32

AdBlue® Production Line – AUS32 Models At Atmosfer Makina, we recognize the escalating global demand for AdBlue® (AUS32), also known as Diesel Exhaust Fluid (DEF). This critical solution is indispensable for modern diesel engines equipped with Selective Catalytic Reduction (SCR) technology, enabling them to meet increasingly stringent emission regulations by converting harmful nitrogen oxides (NOx) into harmless nitrogen and water vapor. As a leader in chemical process engineering, we’ve dedicated ourselves to developing and offering a range of advanced AdBlue® Production Line models designed to empower businesses with the ability to manufacture high-quality AUS32 directly on-site. This approach not only ensures a consistent and reliable supply but also delivers significant economic and operational advantages. The decision to invest in an on-site AdBlue® production line is a strategic one, particularly for large fleet operators, logistics companies, mining operations, marine businesses, and other industrial consumers with high and consistent demand. Relying solely on external suppliers for AdBlue® can expose operations to unpredictable market fluctuations, potential supply chain disruptions, and the logistical complexities of transporting and storing large volumes of liquid. Our diverse range of AdBlue® Production Line models directly addresses these challenges, offering a robust, self-sufficient, and cost-effective solution. Our models are carefully engineered to cater to a broad spectrum of production capacities, ensuring that every client, regardless of their scale of operation, can find a system that perfectly aligns with their specific needs. From compact units suitable for moderate daily consumption to large-scale industrial systems designed for continuous, high-volume output, Atmosfer Makina provides a tailored solution. Each AdBlue® production line model is a complete, turnkey solution, minimizing on-site installation time and complexity. We focus on transforming high-purity urea for DEF into ISO 22241 compliant AdBlue®, ensuring the integrity and longevity of your SCR systems. Our commitment to innovation means that every model incorporates cutting-edge technology, robust construction, and intuitive automation. This ensures reliable performance, consistent product quality, and ease of operation. We believe that empowering our clients with the capability to produce their own AUS32 on-site is a fundamental step towards greater operational control, improved cost efficiency, and a more sustainable future in emission control. Options At Atmosfer Makina, we understand that while our standard AdBlue® Production Line models offer exceptional performance, specific operational requirements and environmental conditions can necessitate additional features. That’s why we offer a comprehensive suite of options that allow for extensive customization, ensuring your AUS32 production line is perfectly tailored to your unique needs. These options enhance efficiency, optimize quality, and streamline your entire AdBlue® manufacturing process. Enhanced urea filtration The purity of AdBlue® (AUS32) is absolutely paramount for the protection and longevity of Selective Catalytic Reduction (SCR) systems. Even microscopic particulate impurities can lead to blockages or damage within the catalytic converter, resulting in costly repairs and reduced engine efficiency. While our standard AdBlue® Production Line models incorporate robust multi-stage filtration systems designed to meet ISO 22241 standards, some operational environments or specific applications demand an even higher level of purity assurance. For such demanding scenarios, Atmosfer Makina offers an enhanced urea filtration option. This advanced feature integrates additional, finer filtration stages directly into the AdBlue® manufacturing process. This means that after the urea for DEF has been dissolved in demineralized water, the resulting solution undergoes an even more rigorous purification. This optional filtration mechanism captures the minutest insoluble particles, ensuring that the final AUS32 product is exceptionally pure. This enhanced urea filtration is particularly beneficial for clients who: Operate in highly sensitive environments where even minimal impurities could pose a risk. Procure urea for DEF from sources where consistency in purity might occasionally vary, requiring an additional safeguard. Wish to maximize the lifespan and performance of their SCR systems by providing the cleanest possible AdBlue®. By choosing the enhanced urea filtration option, you invest in an added layer of quality assurance, further protecting your valuable diesel engine assets and guaranteeing the highest possible standard for your on-site AdBlue® production. Low energy heating Maintaining optimal temperature during the urea dissolution process is crucial for efficient and consistent AdBlue® manufacturing. In colder climates or during winter months, the temperature of incoming demineralized water can drop, slowing down the dissolution rate of urea for DEF and potentially impacting production capacity. Traditional heating methods can be energy-intensive, adding to operational costs. Atmosfer Makina addresses this challenge with our low energy heating option for the AdBlue® Production Line. This feature incorporates highly efficient heating elements and advanced temperature control systems that are specifically designed to minimize energy consumption while effectively warming the demineralized water to the ideal temperature range for urea dissolution (typically between 25-40°C). The benefits of implementing a low energy heating system include: Consistent Production Rates: Ensures that the dissolution process remains efficient regardless of ambient temperature, maintaining stable AUS32 output. Optimized Dissolution: Warmer water accelerates the dissolution of urea for DEF, reducing batch times and increasing overall efficiency of the AdBlue® manufacturing process. Reduced Energy Costs: Utilizes advanced, energy-efficient technology to minimize power consumption, contributing to lower operational expenditures over the long term. Prevents Crystallization: Helps prevent the formation of urea crystals, which can occur if dissolution is inefficient in cold conditions, safeguarding system components. This low energy heating option is a smart investment for any AdBlue® Production Line operating in variable climates, ensuring uninterrupted and cost-effective AUS32 manufacturing throughout the year. Storage Once the AdBlue® (AUS32) has been produced to the highest quality standards by our AdBlue® Production Line, efficient and safe storage becomes a critical next step before distribution or direct use. Atmosfer Makina offers a range of comprehensive storage solutions designed to seamlessly integrate with your AdBlue® manufacturing process, ensuring the integrity and ready availability of your finished product. Proper storage is vital to maintain the quality and extend the shelf life of AdBlue®. AdBlue® is sensitive to contamination and extreme temperatures. Our storage solutions are engineered with these factors in mind: Material Compatibility: Our storage tanks are constructed from materials that are fully compatible with AdBlue®, such as high-grade stainless steel or

On-Site AdBlue® Production: AUS32 & DEF Manufacturing Process

On-Site AdBlue® Production: AUS32 & DEF Manufacturing Process Client Case Study: Sustainable AdBlue® Production for the Energy Sector At Atmosfer Makina, we specialize in providing innovative solutions for critical industrial needs. Today, we’re highlighting a powerful client case study on how our AdBlue® manufacturing process transformed supply for a leading energy sector player. This demonstrates the significant advantages of on-site AdBlue® production, emphasizing our commitment to both environmental responsibility and operational efficiency. The energy sector, heavily reliant on diesel engines for generators and machinery, faces stringent NOx emission regulations. Selective Catalytic Reduction (SCR) systems are the standard solution, using AdBlue® (AUS32, DEF). Traditionally, securing a consistent and cost-effective AdBlue® supply, especially in remote energy operations, has presented logistical and financial hurdles, including high transport costs and supply chain vulnerabilities. Our client, a major energy producer, sought to overcome these challenges. They needed full control over their AdBlue® supply, guaranteed ISO 22241 quality, and a reduced environmental footprint. Atmosfer Makina delivered a customized, autonomous AdBlue® manufacturing facility for on-site production, proving the immense value of our turnkey solutions in the AdBlue® manufacturing process. Why On-Site AdBlue® Production is Environmentally and Economically Preferable On-site AdBlue® production through Atmosfer Makina’s solutions offers compelling environmental and economic advantages over conventional supply methods. Economically, the primary benefit is substantial cost savings. By producing AdBlue® at your facility using urea for DEF, you cut out expenses like freight, storage at third-party distribution centers, and reseller margins. Urea for DEF is a dry granular product, making it significantly cheaper and easier to transport and store in bulk than liquid AdBlue®. This, combined with bulk urea purchasing, delivers a rapid return on investment and sustained savings. Our automated processes also minimize labor costs, giving you greater budgetary control and insulating you from market volatility. Environmentally, on-site AdBlue® production greatly reduces your carbon footprint. Traditional supply chains involve extensive transportation of liquid AdBlue®, generating significant greenhouse gas emissions. By manufacturing on-site, you drastically reduce this transport, leading to lower carbon emissions and a greener operational profile. It also means less road congestion and reduced risk of transportation-related spills, enhancing overall environmental safety. Furthermore, on-site production ensures unparalleled supply security and independence. For critical energy operations, uninterrupted AdBlue® supply is vital. Our AdBlue® manufacturing facility mitigates disruption risks, allowing you to produce AdBlue® on demand, guaranteeing continuous supply regardless of external market or logistical challenges. Lastly, on-site AdBlue® production provides superior quality control. AdBlue® quality directly impacts SCR system performance. Our integrated quality assurance systems continuously monitor the AdBlue® manufacturing process to ensure strict adherence to the ISO 22241 standard. This guarantees consistently pure and correctly concentrated AUS32, protecting your assets and optimizing emission reduction. Key Components of the AdBlue® Manufacturing Facility An Atmosfer Makina AdBlue® manufacturing facility is a meticulously engineered, self-contained system comprised of essential key components designed for efficient, high-quality AdBlue® (AUS32, DEF) production from urea for DEF. Central to the facility is the Urea Storage and Feeding System, which safely stores and precisely delivers granular urea for DEF into the process. The Demineralized Water Production Unit employs advanced water treatment (like reverse osmosis) to create the high-purity water crucial for AdBlue®. An energy-efficient water heating option can optimize urea dissolution, especially in colder climates. The heart of the AdBlue® manufacturing process is the Mixing and Dissolution Reactor, where urea for DEF is thoroughly dissolved in demineralized water to achieve the precise 32.5% concentration. This process is fully automated with sensors monitoring parameters. Following dissolution, the Filtration System ensures final purity by removing impurities. We offer an enhanced urea filtration option for the highest purity demands. Finally, the Quality Control and Monitoring System continuously measures concentration, conductivity, and other parameters, governed by a PLC. This intelligent system ensures consistent ISO 22241 compliant quality, minimal errors, and comprehensive data logging for every batch of AUS32. Urea Dissolution: Process Flow and Automation The urea dissolution stage is fundamental in the AdBlue® manufacturing process. It converts solid urea for DEF into liquid AUS32. Our process flow prioritizes precision and advanced automation. The process begins with automated transfer of urea for DEF from storage into a mixing tank. Simultaneously, demineralized water (potentially heated via the energy-efficient water heating option to 25-40°C) is precisely dosed. This temperature range is crucial for rapid and complete urea dissolution, preventing crystallization. Specialized agitators ensure homogeneous mixing, while real-time temperature and conductivity sensors monitor the solution. Conductivity accurately indicates urea concentration as it dissolves. Our sophisticated automation system, driven by a central PLC, orchestrates this entire process. It receives sensor data to dynamically adjust dosing rates of urea for DEF and water, maintaining the exact 32.5% concentration for AdBlue®. This high level of automation eliminates manual variability, reduces errors, and guarantees consistent quality. Detailed logging of all parameters ensures traceability and quality assurance for every AUS32 batch. Advanced Monitoring and Filtration Technologies Atmosfer Makina’s commitment to top-tier AdBlue® (AUS32, DEF) relies on our advanced monitoring and filtration technologies. These are vital for ensuring every liter produced meets the stringent ISO 22241 quality standard. Advanced Monitoring: High-precision sensors continuously track urea concentration, temperature, pH, and electrical conductivity (a key indicator of purity and concentration). A sophisticated PLC uses this real-time data to make instant adjustments, ensuring consistent quality. Proactive diagnostics, alarms, and detailed data logging provide comprehensive oversight and traceability for continuous AdBlue® production. Advanced Filtration Technologies: Purity is critical to protect SCR systems. Our AdBlue® manufacturing facilities incorporate multi-stage filtration technologies to remove impurities from urea for DEF and water. This includes pre-filtration and fine filtration. We offer an enhanced urea filtration option for the absolute highest purity requirements, safeguarding sensitive SCR catalysts. These systems are designed for minimal maintenance and maximum efficiency. Storage, Loading, and Supervision of Finished AdBlue® Once AdBlue® manufacturing process is complete and quality-approved, efficient storage, loading, and supervision of finished AdBlue® are crucial. Atmosfer Makina provides integrated solutions for these post-production steps, ensuring product integrity and availability. Our storage tank options are specifically designed for AdBlue®, made from compatible materials

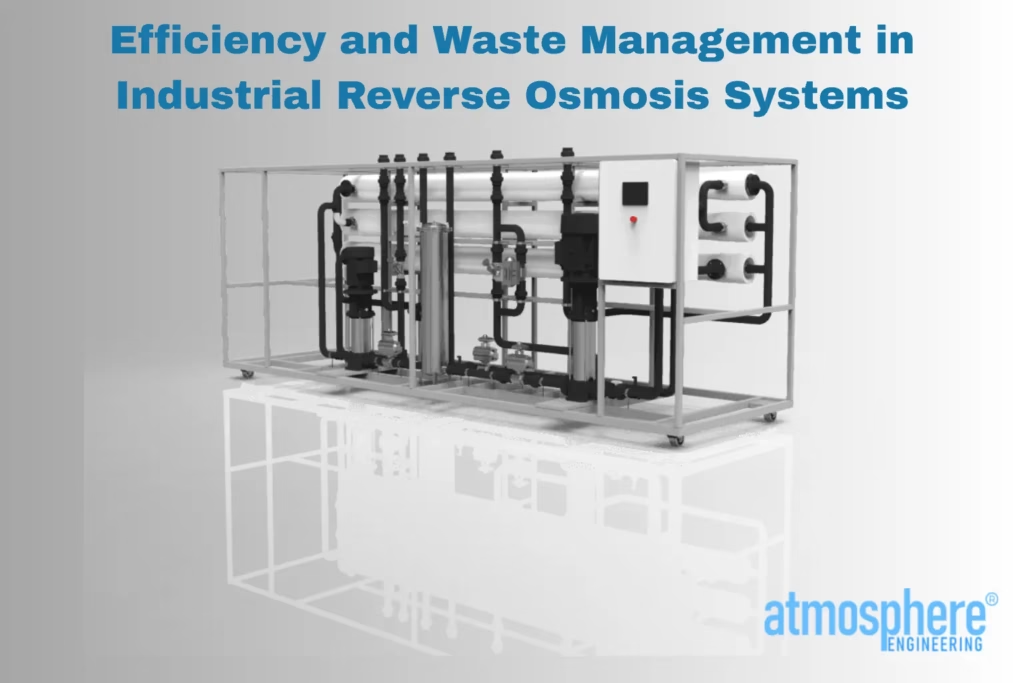

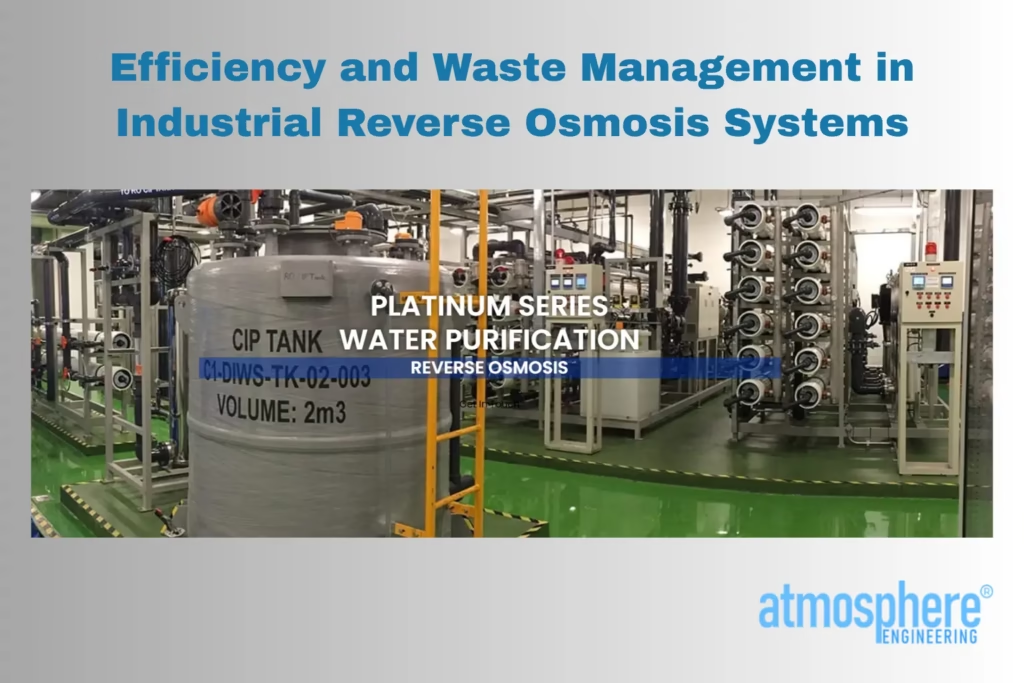

Efficiency and Waste Management in Industrial Reverse Osmosis Systems

Efficiency and Waste Management in Industrial Reverse Osmosis Systems In the demanding landscape of modern industry, industrial Reverse Osmosis (RO) systems are essential, serving as the core technology for producing high-purity water vital for processes ranging from boiler feed and cooling towers to pharmaceutical production and food processing. However, the true measure of a successful RO system extends beyond the mere quality of the product water; it lies in its efficiency and its approach to waste management. A poorly optimized RO system is a drain on resources—wasting valuable water, consuming excessive energy, and generating large volumes of costly-to-dispose-of concentrate. At Atmosfer Makina, we specialize in designing, manufacturing, and supporting high-efficiency RO water treatment solutions that redefine performance. We see efficiency not as an option, but as the only path to sustainable and profitable operation. This comprehensive guide, written from our expertise, delves into the critical factors—from molecular-level membrane technology to strategic waste recycling—that dictate the overall efficiency and waste management success of your industrial RO system. The Role of Pre-treatment and Membrane Technologies The RO membrane is the heart of the system, but its performance is fundamentally reliant on the quality of the water it receives. The greatest threat to RO efficiency is membrane fouling and scaling, which necessitate frequent, expensive cleaning and ultimately reduce the membrane’s lifespan. The solution to this challenge lies in meticulous pre-treatment and the strategic selection of membrane technologies. Mastering Pre-treatment: The Foundation of RO Efficiency No matter the source—municipal supply, well water, or surface water—the feed water must be conditioned before it reaches the sensitive RO membranes. Pre-treatment is the shield that protects the membrane, and its role is paramount in maintaining industrial RO efficiency. We integrate robust, multi-stage pre-treatment systems to remove suspended solids, colloids, organic matter, and hardness: Filtration: This includes multimedia filters, activated carbon filters, and micro-filtration systems to remove particulate matter and chlorine (which damages the membrane). Softening and Antiscalant Dosing: For water with high mineral content (hardness), a water softener or precise antiscalant dosing system is used. Antiscalants work to keep mineral salts like calcium and silica dissolved in the water, preventing them from precipitating and forming scale on the membrane surface. Without effective scale control, the membrane’s water production rapidly declines, and energy consumption soars. Chemical Conditioning: Sometimes, pH adjustment is necessary to optimize the effectiveness of other treatments or to prevent the oxidation of the membrane material. By meticulously removing or neutralizing these contaminants in the pre-treatment stage, we ensure the RO membrane operates under optimal conditions, maximizing its recovery rate and minimizing the generation of reject water. Selecting High-Efficiency Membrane Technologies The membrane itself is a key component of industrial RO efficiency. At Atmosfer Makina, we specify high-efficiency membranes designed for high flux (flow rate) and low energy consumption. Low-Pressure Membranes: Modern RO membrane technology has advanced to the point where high purity can be achieved at significantly lower operating pressures than was previously possible. Using low-pressure membranes directly translates to reduced energy consumption for the high-pressure pumps, offering an immediate and substantial operational cost reduction. Fouling-Resistant Membranes: For challenging industrial applications (e.g., high organic load), specialized fouling-resistant membranes are employed. While they may have a higher initial cost, their longevity and reduced need for cleaning lead to superior long-term system efficiency and lower maintenance costs. The Impact of Maintenance and Cleaning on Efficiency Even the most sophisticated RO system will degrade without a rigorous, proactive maintenance strategy. Maintenance and cleaning are not merely corrective actions; they are essential preventive measures that directly impact the system’s long-term efficiency and waste management success. Proactive Monitoring: The Efficiency Barometer A well-managed industrial RO system relies on continuous performance monitoring. Key indicators we track include: Normalized Permeate Flow: A drop in flow indicates fouling or scaling. Salt Rejection Rate: A drop in salt rejection indicates membrane damage or excessive scaling. Differential Pressure: An increase in pressure across the membrane train is a definitive sign of fouling buildup. At Atmosfer Makina, our industrial RO systems are equipped with automated monitoring and logging capabilities. By tracking these metrics, our clients can identify problems early, initiating corrective action before a small issue becomes a massive, costly performance failure. Proactive monitoring prevents the system from running inefficiently, which would generate more reject water than necessary. Effective Chemical Cleaning (CIP) When performance metrics fall outside the acceptable range, Chemical-in-Place (CIP) cleaning is necessary. The success of this cleaning process is crucial for recovering system efficiency. Effective cleaning involves: Correct Diagnosis: Determining whether the fouling is due to organic material, biological growth, or mineral scaling is key, as each requires a different chemical formulation. Precise Procedure: The cleaning solution concentration, temperature, and flow rate must be meticulously controlled to effectively remove the foulants without damaging the delicate membrane material. We provide our clients with detailed CIP procedures and training, ensuring they use the right chemicals and methods to fully restore the membrane to its optimal performance level, thereby maximizing water recovery and minimizing the volume of RO concentrate. Improper cleaning is the single fastest way to destroy membranes and lock the system into a state of low efficiency and high wastewater production. Sustainable Management Strategies In today’s regulatory climate, water management must align with sustainable management strategies. For industrial RO systems, this means moving toward minimizing the overall water footprint and considering the entire lifecycle of the system. Water Footprint Reduction: From Feed to Discharge A sustainable industrial RO system maximizes the utilization of every drop of water. This involves: High Recovery RO Systems: As discussed, implementing multi-stage, high-pressure, or Closed-Circuit Reverse Osmosis (CCRO) technologies to push the water recovery rate above 90% or higher. High recovery directly reduces the volume of wastewater generated. Energy Efficiency: Integrating Energy Recovery Devices (ERDs) like Permeate Pumps to significantly cut the system’s energy consumption. Reduced energy use translates into a lower carbon footprint for the water production process. Chemical Management: Optimizing the use of pre-treatment chemicals, ensuring the smallest possible dosage is used while maintaining effective protection

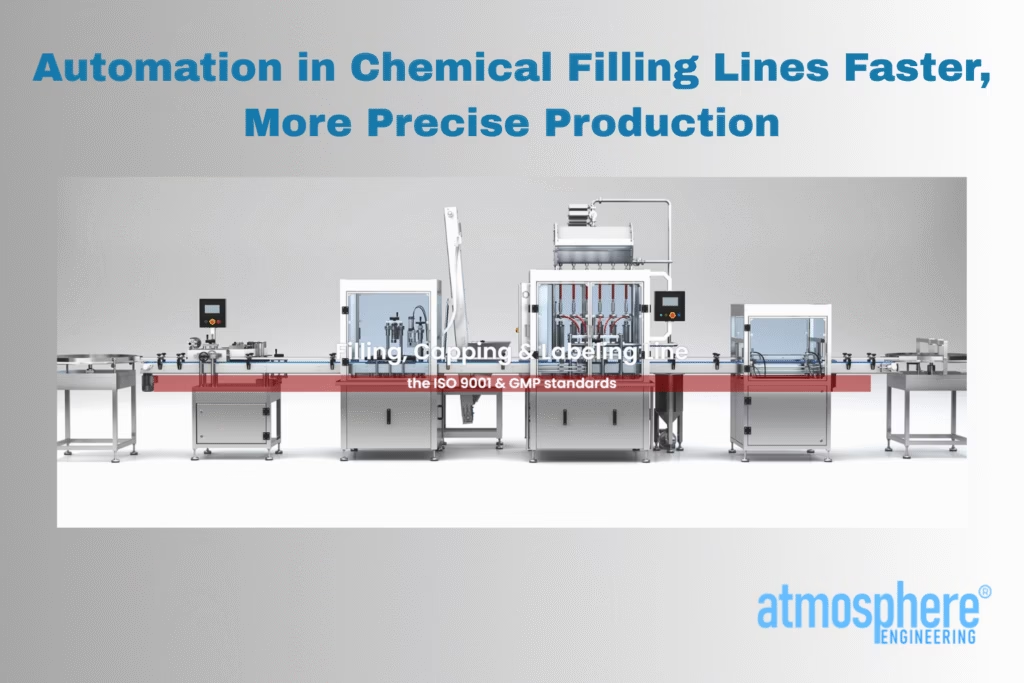

Automation in Chemical Filling Lines: Faster, More Precise Production

Automation in Chemical Filling Lines: Faster, More Precise Production Welcome to the future of chemical manufacturing. At Atmosfer Makina, we understand that in the chemical industry, speed is nothing without precision. As a leading manufacturer of high-performance chemical filling machinery and complete packaging line solutions, we’ve seen firsthand how the integration of automation transforms an operation from merely productive to genuinely revolutionary. This transformation is driven by our commitment to engineering excellence, focusing on systems that deliver unparalleled accuracy, speed, and reliability. The demands on chemical producers are relentless: strict regulatory compliance, increasing product diversity, and the need for cost-efficient scaling. Manual or semi-automatic processes simply can’t keep pace or guarantee the batch-to-batch consistency that defines quality. This is why investing in automated chemical filling lines isn’t just an upgrade; it’s a strategic imperative for long-term success. We are here to show you how our expertly designed filling and packaging systems—from automatic filling machines to smart control solutions—are setting new standards for chemical production efficiency and quality across the globe. The Core of Efficiency: Automated Filling and Control Systems The heart of an optimized chemical production line lies in its automation. By replacing manual processes with precision-engineered machinery, we eliminate the variability and bottlenecks that plague traditional operations. Automatic Filling and Labelling Systems In the chemical sector, whether you are dealing with corrosive acids, viscous solvents, or delicate liquid detergents, the filling process is the most critical step for both product integrity and safety. Our automatic filling solutions are designed to handle a vast spectrum of chemical products and container types—from small bottles to large jerrycans and drums—with exceptional speed and repeatability. Our filling machines utilize advanced technologies such as magnetic flow meters or weight-based filling systems to achieve superior dosing accuracy. This means every single container receives the precise amount of product, drastically reducing the risk of costly overfilling or underfilling. For highly corrosive materials, our systems are built with chemically resistant materials (like specialized stainless steel or PTFE) to ensure maximum durability and operator safety. But filling is only half the battle. A complete packaging line solution requires seamless integration with automatic labelling machines. Precision Label Application: Our automatic label applicators ensure that every label—whether it’s a single front label, a wrap-around, or a multi-panel hazardous goods label—is applied perfectly straight, without wrinkles or bubbles, and in the exact same position on every single unit. This attention to detail is vital for brand consistency and adherence to regulatory standards for chemical packaging. Integrated Coding and Marking: Furthermore, our systems incorporate high-speed coding and marking solutions (like inkjet or laser coders) to print essential information like batch codes, expiry dates, and serialization data. This integration is crucial for product traceability and inventory management, forming a key pillar of a modern, compliant production line. By deploying an integrated automatic filling and labelling system, our clients achieve phenomenal increases in throughput capacity while simultaneously boosting product presentation and regulatory compliance. The Impact of Smart Control Systems The true intelligence in our chemical filling lines comes from the smart control systems that power them. These are not merely on/off switches; they are sophisticated, interconnected Industrial IoT (IIoT) platforms that govern the entire packaging process. Our systems are controlled via intuitive HMI (Human-Machine Interface) touchscreens, giving operators complete, real-time command of the line. Key features of these advanced control systems include: Real-Time Monitoring and Diagnostics: Operators can view live data on filling speed, pressure, temperature, and machine status. The system constantly runs predictive diagnostics, alerting teams to potential mechanical or process issues before they lead to downtime. This proactive maintenance approach maximizes operational efficiency and machine lifespan. Recipe Management: For businesses handling diverse chemical products (different viscosities, densities, and container sizes), digital recipe management is a game-changer. Operators can switch between different product settings and container formats with a few taps. The smart system automatically adjusts all parameters—fill volume, conveyor speed, capping torque, and label placement—ensuring a rapid product changeover with minimal human error. This feature alone drastically cuts the time and labor associated with format adjustments. Data Logging and Reporting: Every action, every fill, and every sensor reading is recorded. This detailed data logging provides a comprehensive audit trail critical for regulatory compliance (e.g., ISO, FDA, REACH). This data is also invaluable for process optimization, allowing engineers to analyze production trends and continually refine performance for maximum yield and efficiency. In essence, our smart control systems transform raw machinery into an intelligent, adaptive production asset, ensuring peak performance and providing the data foundation for a truly digital chemical plant. Beyond Speed: Quality and Sustainability The benefits of chemical filling automation extend far beyond simple speed. The inherent precision and consistency of automated systems directly address the most significant challenges in the chemical industry: controlling waste and maintaining unblemished product quality across every single batch. Waste Reduction through Precision Product waste, or product loss, is one of the most substantial hidden costs in manual and semi-automatic filling operations. Overfilling, spills, container rejections due to inaccurate fills or poor labelling, and lengthy startup/shutdown processes all contribute to significant material loss. Atmosfer Makina’s automated solutions turn this equation on its head. Minimizing Overfill: The primary driver of waste is overfilling. Our high-precision filling technology guarantees a fill accuracy that is often superior to the industry standard. By tightening the tolerance on fill volume, we ensure that you are not giving away valuable product in every container. For high-volume production, these fractional savings translate into a massive reduction in raw material consumption and a significant boost to your bottom line. Reduced Spillage and Rejects: Automated, synchronized movement of containers, coupled with features like anti-foaming and anti-splash nozzles, virtually eliminates product spillage. Furthermore, the reliable precision of both the filling and automatic labelling process means fewer containers are rejected for incorrect fill levels or misapplied labels, which would otherwise have to be scrapped or reworked. Efficient Clean-in-Place (CIP) Systems: Chemical product changeovers often require extensive cleaning. Our machinery is designed for quick and efficient CIP processes,

Efficiency and Waste Management in Industrial Reverse Osmosis Systems

Efficiency and Waste Management in Industrial Reverse Osmosis Systems In the demanding landscape of modern industry, industrial Reverse Osmosis (RO) systems are essential, serving as the core technology for producing high-purity water vital for processes ranging from boiler feed and cooling towers to pharmaceutical production and food processing. However, the true measure of a successful RO system extends beyond the mere quality of the product water; it lies in its efficiency and its approach to waste management. A poorly optimized RO system is a drain on resources—wasting valuable water, consuming excessive energy, and generating large volumes of costly-to-dispose-of concentrate. At Atmosfer Makina, we specialize in designing, manufacturing, and supporting high-efficiency RO water treatment solutions that redefine performance. We see efficiency not as an option, but as the only path to sustainable and profitable operation. This comprehensive guide, written from our expertise, delves into the critical factors—from molecular-level membrane technology to strategic waste recycling—that dictate the overall efficiency and waste management success of your industrial RO system. The Role of Pre-treatment and Membrane Technologies The RO membrane is the heart of the system, but its performance is fundamentally reliant on the quality of the water it receives. The greatest threat to RO efficiency is membrane fouling and scaling, which necessitate frequent, expensive cleaning and ultimately reduce the membrane’s lifespan. The solution to this challenge lies in meticulous pre-treatment and the strategic selection of membrane technologies. Mastering Pre-treatment: The Foundation of RO Efficiency No matter the source—municipal supply, well water, or surface water—the feed water must be conditioned before it reaches the sensitive RO membranes. Pre-treatment is the shield that protects the membrane, and its role is paramount in maintaining industrial RO efficiency. We integrate robust, multi-stage pre-treatment systems to remove suspended solids, colloids, organic matter, and hardness: Filtration: This includes multimedia filters, activated carbon filters, and micro-filtration systems to remove particulate matter and chlorine (which damages the membrane). Softening and Antiscalant Dosing: For water with high mineral content (hardness), a water softener or precise antiscalant dosing system is used. Antiscalants work to keep mineral salts like calcium and silica dissolved in the water, preventing them from precipitating and forming scale on the membrane surface. Without effective scale control, the membrane’s water production rapidly declines, and energy consumption soars. Chemical Conditioning: Sometimes, pH adjustment is necessary to optimize the effectiveness of other treatments or to prevent the oxidation of the membrane material. By meticulously removing or neutralizing these contaminants in the pre-treatment stage, we ensure the RO membrane operates under optimal conditions, maximizing its recovery rate and minimizing the generation of reject water. Selecting High-Efficiency Membrane Technologies The membrane itself is a key component of industrial RO efficiency. At Atmosfer Makina, we specify high-efficiency membranes designed for high flux (flow rate) and low energy consumption. Low-Pressure Membranes: Modern RO membrane technology has advanced to the point where high purity can be achieved at significantly lower operating pressures than was previously possible. Using low-pressure membranes directly translates to reduced energy consumption for the high-pressure pumps, offering an immediate and substantial operational cost reduction. Fouling-Resistant Membranes: For challenging industrial applications (e.g., high organic load), specialized fouling-resistant membranes are employed. While they may have a higher initial cost, their longevity and reduced need for cleaning lead to superior long-term system efficiency and lower maintenance costs. The Impact of Maintenance and Cleaning on Efficiency Even the most sophisticated RO system will degrade without a rigorous, proactive maintenance strategy. Maintenance and cleaning are not merely corrective actions; they are essential preventive measures that directly impact the system’s long-term efficiency and waste management success. Proactive Monitoring: The Efficiency Barometer A well-managed industrial RO system relies on continuous performance monitoring. Key indicators we track include: Normalized Permeate Flow: A drop in flow indicates fouling or scaling. Salt Rejection Rate: A drop in salt rejection indicates membrane damage or excessive scaling. Differential Pressure: An increase in pressure across the membrane train is a definitive sign of fouling buildup. At Atmosfer Makina, our industrial RO systems are equipped with automated monitoring and logging capabilities. By tracking these metrics, our clients can identify problems early, initiating corrective action before a small issue becomes a massive, costly performance failure. Proactive monitoring prevents the system from running inefficiently, which would generate more reject water than necessary. Effective Chemical Cleaning (CIP) When performance metrics fall outside the acceptable range, Chemical-in-Place (CIP) cleaning is necessary. The success of this cleaning process is crucial for recovering system efficiency. Effective cleaning involves: Correct Diagnosis: Determining whether the fouling is due to organic material, biological growth, or mineral scaling is key, as each requires a different chemical formulation. Precise Procedure: The cleaning solution concentration, temperature, and flow rate must be meticulously controlled to effectively remove the foulants without damaging the delicate membrane material. We provide our clients with detailed CIP procedures and training, ensuring they use the right chemicals and methods to fully restore the membrane to its optimal performance level, thereby maximizing water recovery and minimizing the volume of RO concentrate. Improper cleaning is the single fastest way to destroy membranes and lock the system into a state of low efficiency and high wastewater production. Sustainable Management Strategies In today’s regulatory climate, water management must align with sustainable management strategies. For industrial RO systems, this means moving toward minimizing the overall water footprint and considering the entire lifecycle of the system. Water Footprint Reduction: From Feed to Discharge A sustainable industrial RO system maximizes the utilization of every drop of water. This involves: High Recovery RO Systems: As discussed, implementing multi-stage, high-pressure, or Closed-Circuit Reverse Osmosis (CCRO) technologies to push the water recovery rate above 90% or higher. High recovery directly reduces the volume of wastewater generated. Energy Efficiency: Integrating Energy Recovery Devices (ERDs) like Permeate Pumps to significantly cut the system’s energy consumption. Reduced energy use translates into a lower carbon footprint for the water production process. Chemical Management: Optimizing the use of pre-treatment chemicals, ensuring the smallest possible dosage is used while maintaining effective protection

Wastewater Reduction and Recovery Strategies in Reverse Osmosis Systems

Wastewater Reduction and Recovery Strategies in Reverse Osmosis Systems In industrial and municipal water treatment, Reverse Osmosis (RO) stands as the most vital technology for producing high-purity water. However, as an integral component of its efficiency, the RO process inherently generates a concentrated stream of reject water—often referred to as RO concentrate or wastewater. In an era defined by water scarcity, escalating operational costs, and stringent environmental regulations, managing this reject stream is no longer a simple disposal issue; it is a critical strategic challenge. At Atmosfer Makina, we understand that true excellence in RO system design lies not just in the purity of the permeate (product water) but in the overall efficiency and sustainability of the operation. Our mission is to move beyond standard RO systems by incorporating advanced wastewater reduction and recovery strategies that maximize water utilization while minimizing your operational footprint and expenditure. This comprehensive guide explores the innovative techniques and modern technologies we integrate into our RO water treatment solutions to transform reject water from a costly liability into a valuable resource, setting a new standard for sustainable industrial water management. Wastewater Recovery Techniques: Transforming Reject Water into a Resource Traditional Reverse Osmosis systems often operate with a recovery rate between 70% and 85%. This means that for every 100 liters of feed water, 15 to 30 liters are discharged as reject. For large-scale industrial operations, this represents massive volumes of wasted water and high disposal costs. To counteract this inefficiency, Atmosfer Makina employs advanced techniques designed to squeeze maximum utility out of the feed water, significantly increasing the overall system recovery rate. These techniques focus on treating the RO concentrate itself to facilitate further filtration. The Power of RO Staging and Stacking One of the foundational techniques we use is optimizing the RO system architecture through staging. Standard RO systems may have a single array, but high-efficiency designs utilize a multi-stage approach where the reject water from the first stage is fed into a second, lower-pressure stage. This is known as staging or cascading. The goal is to maximize the osmotic pressure differential applied to the concentrate stream. By passing the concentrate through a second or even a third set of membranes, we can push more water through before the concentration of dissolved solids reaches the saturation point (scaling threshold). This method alone can boost the recovery rate by several percentage points, drastically cutting wastewater volume. Concentrate Treatment and Pretreatment Before sending the reject water to a subsequent membrane stage, sophisticated pretreatment or in-line chemical treatment may be necessary. As the feed water is concentrated, the risk of scaling (the precipitation of mineral salts like calcium sulfate and silica) skyrockets. We employ advanced antiscalant dosing and sometimes specialized pH adjustment to keep the concentrated mineral salts in solution for longer. This chemical manipulation effectively raises the permissible recovery rate by delaying the scaling point, allowing the membrane to treat higher-concentration water. This critical step ensures that the secondary RO stages, which operate under extreme concentration conditions, function reliably without constant membrane fouling. By integrating these specialized wastewater recovery techniques, Atmosfer Makina ensures that our Reverse Osmosis systems achieve peak efficiency, helping our clients save millions of liters of water annually. The Advantage of Permeate Pumps (in RO systems) While staging and pretreatment focus on the water’s chemical state, energy consumption remains a major operational hurdle in Reverse Osmosis. High-pressure pumps consume significant electricity to overcome the natural osmotic pressure and force water across the membrane. A critical innovation we leverage to mitigate this energy use is the Permeate Pump or Energy Recovery Device (ERD). Harnessing Pressure for Efficiency In a standard RO system, the highly pressurized RO concentrate (the waste stream) is simply discharged, and the energy contained within that pressure is lost forever. An Energy Recovery Device (ERD) or Permeate Pump captures this latent hydraulic energy. The Permeate Pump operates by using the high pressure of the reject stream to pressurize the feed water entering the membrane vessel. Essentially, the energy that would otherwise be wasted in the drain is transferred directly back to the feed side of the system, reducing the workload on the main high-pressure pump. The Economic and Performance Impact The deployment of Permeate Pumps provides a direct and substantial cost advantage for industrial operations: Lower Energy Consumption: By recycling a significant portion of the reject stream’s energy, the overall energy required for the main pump is drastically reduced—often by 40% to 60%. This results in massive savings on electricity costs, making the operation significantly more cost-effective. Reduced Component Stress: The reduced workload on the high-pressure pump translates into lower wear and tear, extending the pump’s lifespan and lowering maintenance frequency and costs. Stable System Operation: The constant, reliable pressure provided by the ERD ensures more consistent flow across the membranes, optimizing the recovery rate and water quality. At Atmosfer Makina, integrating energy-saving technologies like the Permeate Pump is a standard feature in our high-efficiency RO water treatment solutions. We believe sustainability must be both environmentally responsible and economically viable. Cost and Environmental Gains: The True ROI of Efficiency When an RO system focuses on wastewater reduction and energy recovery, the benefits ripple through the entire operation, leading to significant cost and environmental gains. Economic Advantages The combination of higher water recovery and reduced energy consumption directly impacts a company’s bottom line: Lower Water Purchase Costs: Maximizing the conversion of feed water to product water (permeate) means less raw water needs to be purchased or processed from source. This is especially critical in regions where water tariffs are high. Reduced Disposal Fees: For every cubic meter of RO concentrate that is recovered and converted into product water, the volume of water needing disposal is reduced. Disposal of highly saline or chemically concentrated wastewater is often extremely expensive, and minimizing this volume provides immediate and sustained cost savings. Accelerated ROI: The savings generated from reduced energy consumption (via Permeate Pumps) and lower disposal fees allow the investment in the high-efficiency RO

Why Global AdBlue® Manufacturers Prefer “Turkish Made” Equipment

Why Global AdBlue® Manufacturers Prefer “Turkish Made” Equipment The global market for Diesel Exhaust Fluid (DEF), widely known by the trademark AdBlue®, is one of the most quality-sensitive and rapidly growing sectors in the world. As regulatory standards tighten and the demand for cleaner engine technology soars, manufacturers across continents are seeking reliable, high-performance, and cost-effective solutions for their AdBlue production plants. In this highly competitive landscape, a trend is emerging: Global AdBlue manufacturers are increasingly choosing Turkish-made equipment. At Atmosfer Makina, we believe this is not a coincidence. It is the culmination of strategic advantages rooted in engineering excellence, comprehensive service models, and a uniquely competitive value proposition. We are proud to be at the forefront of this movement, supplying fully integrated, high-tech AdBlue production systems that set the benchmark for global quality and operational efficiency. This article, written from our perspective as a leading Turkish equipment manufacturer, explores the compelling reasons why international producers are choosing our solutions to power their success. Integrated Systems Offered by Atmosfer Makina The primary reason global companies look to us is the shift from purchasing fragmented machinery to acquiring a fully integrated AdBlue solution. The complexity of meeting ISO 22241 standards—which mandate everything from the specific concentration (32.5% urea) to the absolute elimination of metallic contaminants—demands a cohesive system, not a collection of disparate parts. The Power of End-to-End Integration At Atmosfer Makina, we don’t sell individual components; we deliver an Integrated AdBlue Production Unit. This approach guarantees seamless compatibility and optimized performance across every stage of the DEF manufacturing process. Our systems incorporate all necessary elements into a single, cohesive skid-mounted unit: The Demineralization Unit: We integrate a high-capacity unit to ensure the process water is purified to the exact specifications required by ISO 22241, removing all trace minerals that could compromise the final product. Precise Dosing and Mixing: Our AdBlue Production Units feature advanced, automated dosing technology that precisely controls the ratio of water to the high-purity urea. This crucial step is fully automated to guarantee the mandated 32.5% concentration, eliminating human error and ensuring batch consistency. Multi-Stage Filtration: Built directly into our units is a robust multi-stage filtration system that captures any particulates that may have entered the process. This meticulous filtration is vital for protecting the delicate SCR systems in vehicles and maintaining AdBlue quality. The Purity Mandate (316L Stainless Steel): Every component that contacts the AdBlue solution—from the tanks to the piping and pumps—is constructed using exclusively 316L stainless steel. This is a non-negotiable standard in our Turkish-made equipment, ensuring zero contamination from leaching metals, a fundamental requirement for ISO 22241 compliance. By offering this level of integration, we simplify the investment decision. Our clients bypass the time, cost, and risk associated with sourcing components from multiple vendors and trying to force them to work together. They receive a turnkey AdBlue solution that is built to perform optimally from day one. Securing the Raw Material Supply Chain Our technological offering extends beyond the machinery to the most critical input: the urea. We understand that the purest machinery is useless if the urea is impure. We strongly advocate for and facilitate the supply of high-purity urea for DEF—specifically, Prilled Urea Without UF. This specific urea is manufactured free of the Urea-Formaldehyde (UF) anti-caking coatings and trace metals found in common agricultural urea. By ensuring that our clients have access to this premium, purpose-built urea, we guarantee that their production starts with the highest-grade raw material, securing the final product’s ISO 22241 compliance and protecting the end-user’s vehicle. The integration of our equipment with the required raw material standard is a holistic commitment to quality that global producers recognize and value. Service Advantages from Design to Integration In the heavy industrial equipment sector, the quality of the service package is often more important than the initial price tag. Our advantage in the global market stems from our unique ability to provide comprehensive support that spans the entire project lifecycle, from initial conceptualization through years of operational life. Custom Design and Engineering Excellence Every market and location has unique challenges, from ambient temperatures that can cause AdBlue to freeze or degrade, to local power infrastructure constraints. We do not believe in a one-size-fits-all approach. Our service begins with detailed custom engineering. Our in-house team works directly with the client to design the AdBlue plant based on specific output targets, geographical location, and existing infrastructure. This bespoke approach ensures maximum efficiency and adaptability. For instance, we design insulated and heated units for clients in cold climates and optimize footprint for those with limited space. This commitment to tailored AdBlue manufacturing solutions ensures the equipment is perfectly suited to the client’s environment. Seamless Integration and Commissioning The process of moving from a designed blueprint to a live, profitable operation is often the most complex phase of a production plant setup. Our service advantage shines here. As the manufacturer of integrated AdBlue systems, we manage the entire delivery and commissioning process. Our expert technicians travel to the client’s site, ensuring that the modular units are quickly and correctly installed, tested, and fully integrated with the site’s utilities. We pride ourselves on rapid and professional commissioning, which includes comprehensive on-site training. We empower the local operating team with the knowledge to manage the AdBlue equipment autonomously, ensuring they understand all quality control checks and maintenance procedures required to maintain ISO 22241 compliance. This hands-on, partnership-driven integration dramatically reduces downtime and accelerates the client’s time-to-market. Cost-Effective Advantages of Domestic Production One of the most compelling arguments for choosing Turkish-made AdBlue equipment is the unparalleled balance of cost-effectiveness and certified quality. This is not about cutting corners; it is about strategic manufacturing efficiency. High Quality, Competitive Pricing Turkey’s manufacturing ecosystem combines high-level engineering and a skilled, competitive labor force. Unlike some traditional European manufacturing hubs, this model allows us to produce equipment of identical or superior quality (especially regarding the critical 316L stainless steel fabrication and ISO 22241 adherence) but at a significantly more competitive

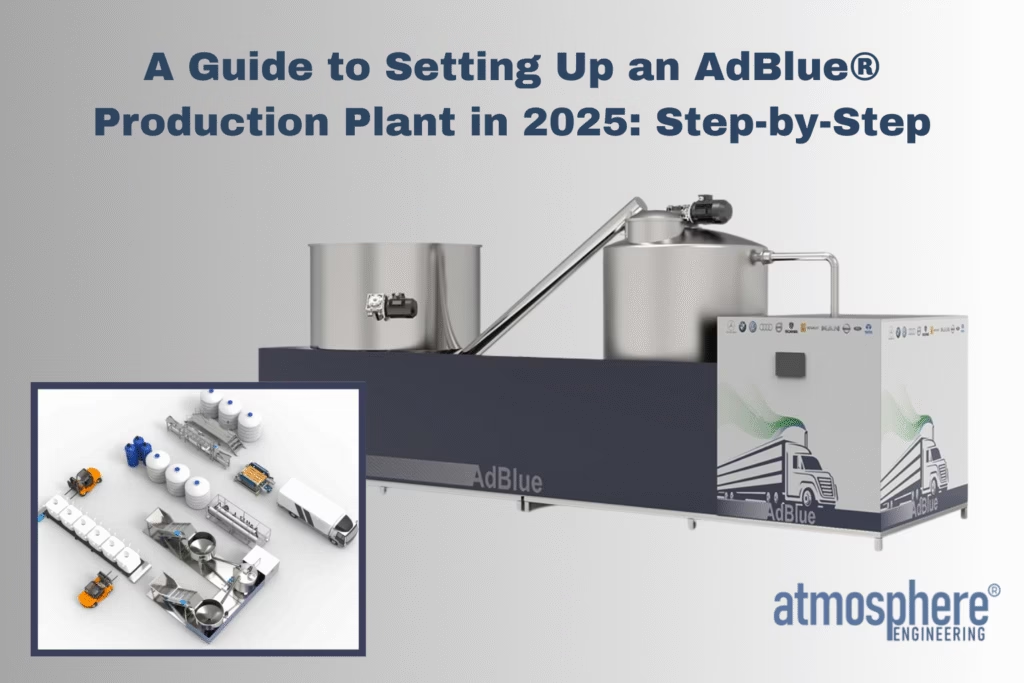

A Guide to Setting Up an AdBlue® Production Plant in 2025: Step-by-Step

A Guide to Setting Up an AdBlue® Production Plant in 2025: Step-by-Step Welcome to the future of DEF (Diesel Exhaust Fluid) manufacturing. As the global push for cleaner air accelerates, the demand for high-quality AdBlue® is reaching unprecedented levels. For entrepreneurs and established industry players alike, 2025 represents a prime opportunity to enter or scale up in this vital market. However, success hinges not on simply mixing water and urea, but on establishing a precise, quality-controlled, and reliable operation. At Atmosfer Makina, we are not just suppliers; we are AdBlue® production specialists. Having pioneered advanced manufacturing solutions for years, we understand that building a plant is a journey, not just a purchase. It requires meticulous planning, the right technology, and an unwavering commitment to purity. This comprehensive guide, written from our perspective as your trusted manufacturing partner, will walk you through the essential steps for establishing a cutting-edge AdBlue® production plant designed for profitability and compliance in 2025 and beyond. Planning and Equipment Selection: The Blueprint for Success The foundation of a profitable AdBlue® manufacturing business is built during the initial planning phase. This is where you transition from a business idea to a concrete operational blueprint. Skimping on planning inevitably leads to operational inefficiencies and costly retrofits later. Market Analysis and Capacity Definition Before selecting a single piece of AdBlue® equipment, you must define your production target. Will you cater to regional logistics companies, national distributors, or international export markets? Your target capacity—whether it’s 50,000 liters per day or 5,000—will dictate the necessary scale of your machinery and storage. A realistic capacity plan ensures you invest in AdBlue® production equipment that is neither oversized (wasting capital) nor undersized (hindering growth). This foresight is paramount in a dynamic market. Core Equipment Selection: Precision is Key The heart of your AdBlue® production facility is the mixing and filtration unit. This system must be capable of handling high-purity urea and deionized water while strictly preventing contamination. At Atmosfer Makina, our modular AdBlue® Production Units are designed with this precision in mind. When selecting equipment, focus on: Material Quality: All components—tanks, piping, valves, and pumps—must be made from Stainless Steel 316L. This is non-negotiable, as lower-grade materials can leach metals into the solution, causing irreparable damage to vehicle SCR systems and violating ISO 22241 standards. Our systems exclusively use high-grade 316L steel to guarantee AdBlue® purity. Dissolution Technology: Efficient dissolution of solid urea is crucial. Our AdBlue® manufacturing units utilize advanced mixing technology to ensure rapid and complete homogenization of the urea into the demineralized water, minimizing energy consumption and speeding up batch times. Filtration Systems: A multi-stage filtration system is essential for removing any particulate matter that could have entered the process from the raw materials or atmosphere. Our units incorporate fine-micron filters that guarantee the final product is pristine, protecting both your filling equipment and the customer’s SCR catalyst. The Raw Material Advantage: High-Purity Urea The quality of your final product is determined by the quality of your raw materials. This is where many producers make a fatal error by using cheaper, agricultural-grade urea. This fertilizer-grade urea contains harmful impurities like aldehydes, heavy metals, and most critically, Urea-Formaldehyde (UF) coatings. Our solution, which we strongly advocate for all new and existing plants, is Prilled Urea Without UF. This product is manufactured specifically for DEF/AdBlue production. Its key advantages are: Ultra-Purity: Guaranteed compliance with ISO 22241 chemical composition requirements. Contaminant-Free: Lacks the UF coatings and trace contaminants found in fertilizer urea that are known to destroy SCR catalysts. Optimal Dissolution: The prilled form allows for easy, quick, and complete dissolution in water, streamlining the manufacturing process. Choosing a high-purity urea for DEF from the outset is the single most effective way to safeguard your investment and brand reputation. Automation and Quality Assurance Processes In the modern AdBlue production industry, manual operations are a liability. To achieve the ISO 22241 standard consistently and maximize efficiency, automation and robust quality assurance (QA) are non-negotiable. Full-Scale Automation Our advanced AdBlue production systems integrate full automation across the entire lifecycle: Raw Material Dosing: Automated flow meters and weighing systems precisely control the ratio of demineralized water to high-purity urea. This ensures the required 32.5% concentration is maintained in every single batch, eliminating human error. Mixing and Transfer: Automated sequence controls manage the mixing time, temperature, and transfer to storage tanks, ensuring the process is optimized for energy efficiency and speed. Filtration Monitoring: Automated sensors monitor filter pressure and flow, alerting operators when maintenance is required or if unexpected contaminants are detected. This prevents the release of substandard product. Automation is the key to maintaining consistency, which is the hallmark of a premium AdBlue brand. It reduces labor costs and ensures that your plant can operate reliably, often on a 24/7 basis, meeting peak market demand. Rigorous Quality Assurance (QA) Procedures Quality assurance in DEF manufacturing extends beyond simply meeting the 32.5% concentration. It involves validating purity at multiple stages. The Three QA Pillars: Raw Material Verification: Before a single kilogram of urea for DEF is mixed, its Certificate of Analysis (COA) must be reviewed. Furthermore, in-house testing for contaminants (like heavy metals) and concentration of the urea solution should be mandatory. In-Process Monitoring: During the mixing and filtration process, automated conductivity meters and refractometers should continuously monitor the concentration. Any deviation triggers an immediate halt and alert, preventing an entire batch from being ruined. Final Product Testing: Every completed batch must be subjected to a final, comprehensive quality control test against the full ISO 22241 specification. This test confirms the correct concentration, absence of suspended matter, and crucially, the level of harmful metallic contaminants. At Atmosfer Makina, we integrate comprehensive quality control solutions directly into our production units, ensuring that compliance is a built-in feature, not an afterthought. This commitment to QA is what differentiates a sustainable AdBlue manufacturing business from a fleeting one. Localization and Scalability: Designing for Growth A smart AdBlue production plant is designed not just for today’s needs, but for tomorrow’s