Urea Dissolving Systems for Industrial Process Efficiency

Industrial sustainability and emission compliance have become critical priorities for modern production facilities. Among the technologies supporting these goals, Urea Dissolving Systems play a central role in preparing high-quality urea solutions for selective catalytic reduction (SCR), AdBlue® production, and various chemical processes. Properly engineered systems ensure process stability, cost efficiency, and regulatory compliance while minimizing operational risks. In this comprehensive guide, we will explore the technical structure, industrial importance, applications, and customized solutions related to Urea Dissolving Systems, with a particular focus on performance optimization and process efficiency. What Are Urea Dissolving Systems? Urea Dissolving Systems are industrial processing units designed to dissolve solid urea granules or prills in water to produce a homogeneous liquid solution at specific concentrations. These systems are widely used in SCR emission control technologies, AdBlue® (DEF – Diesel Exhaust Fluid) production facilities, power plants, and chemical manufacturing industries. The process requires precision in temperature control, mixing intensity, dosing accuracy, and solution quality monitoring. Improper dissolution can lead to crystallization, concentration inconsistencies, and reduced NOx reduction efficiency. Therefore, Urea Dissolving Systems are engineered with automation and advanced process control components to ensure reliable performance. From raw material feeding to final solution storage, each stage within Urea Dissolving Systems is optimized to maintain quality standards and prevent contamination or concentration deviations. Purpose and Industrial Importance of Urea Dissolving Systems The primary purpose of Urea Dissolving Systems is to prepare standardized aqueous urea solutions with precise concentration levels, typically 32.5% for AdBlue® or custom concentrations for industrial processes. These solutions are used in SCR systems to reduce nitrogen oxide (NOx) emissions in diesel engines and industrial exhaust systems. Industrially, Urea Dissolving Systems provide: Consistent solution quality Reduced manual handling of urea Automated concentration control Improved safety standards Reduced operational downtime In large-scale facilities, manual dissolution methods are inefficient and prone to errors. Automated Urea Dissolving Systems eliminate these risks by integrating dosing systems, heating units, mixing tanks, and PLC-controlled automation panels. As global emission standards become stricter, reliable Urea Dissolving Systems have become indispensable components of environmental compliance strategies. Role of Urea Dissolving Systems in Emission Control Selective Catalytic Reduction (SCR) systems rely on high-quality urea solutions to convert harmful nitrogen oxides into harmless nitrogen and water vapor. The efficiency of this reaction depends directly on the consistency of the prepared solution. Properly designed Urea Dissolving Systems ensure: Accurate urea concentration Complete dissolution without residues Prevention of crystallization Stable injection into SCR reactors If the urea solution contains undissolved particles or concentration fluctuations, SCR catalysts may suffer from clogging or reduced conversion efficiency. Therefore, industrial facilities depend on high-performance Urea Dissolving Systems to maintain emission control stability. In power plants, marine engines, heavy industry boilers, and diesel vehicle applications, reliable Urea Dissolving Systems contribute directly to environmental sustainability and regulatory compliance. Technical Characteristics of Urea Dissolving Systems Modern Urea Dissolving Systems are engineered with advanced automation and modular design principles. They integrate mechanical, thermal, and digital control components to ensure process reliability. Key technical characteristics include: Automated dosing and feeding systems Stainless steel mixing tanks Heating elements for temperature regulation Concentration measurement sensors PLC-based control panels Level and conductivity monitoring Anti-crystallization design features The technical structure of Urea Dissolving Systems allows continuous or batch production depending on plant requirements. Customizable capacities enable adaptation for small production facilities as well as large-scale industrial plants. Material selection is also critical. Since urea solutions can be corrosive under certain conditions, Urea Dissolving Systems are typically manufactured using high-grade stainless steel to ensure durability and longevity. Process Control and System Design Efficient process control is the backbone of high-performance Urea Dissolving Systems. Automation ensures precision, reduces labor dependency, and improves safety standards. Automated Urea Dosing Automated dosing units regulate the exact quantity of solid urea entering the dissolution tank. Load cells and dosing screws maintain precise feed rates. In advanced Urea Dissolving Systems, dosing is integrated with real-time concentration feedback to prevent deviation. High-Efficiency Mixing Homogeneous mixing is essential to achieve complete dissolution. High-efficiency agitators in Urea Dissolving Systems ensure uniform distribution of urea granules, preventing sediment formation. Optimized mixing geometry minimizes energy consumption while maximizing dissolution speed. Temperature Management Urea dissolves more effectively within controlled temperature ranges. Integrated heating systems in Urea Dissolving Systems maintain optimal water temperature, accelerating dissolution and preventing crystallization. Temperature sensors continuously monitor system stability. Scalable Capacity Options Industrial requirements vary significantly. Modular Urea Dissolving Systems offer scalable tank volumes and throughput capacities. Whether for small AdBlue® production plants or large industrial SCR facilities, systems can be customized to match operational demands. Applications of Urea Dissolving Systems The versatility ofDissolving Systems allows them to serve multiple industries. Their reliability and precision make them critical components in environmental and chemical processing infrastructures. Industrial Usage Areas AdBlue® Production Plants In AdBlue® manufacturing facilities, Dissolving Systems prepare 32.5% urea solution in compliance with ISO 22241 standards. Consistent concentration and contamination-free production are essential to protect vehicle SCR systems. Chemical Manufacturing Facilities Chemical plants use Dissolving Systems to prepare intermediate solutions for fertilizers, resins, adhesives, and other chemical products. Precision in dissolution directly impacts product quality. Power Plants Thermal power plants rely on SCR technology for emission reduction. High-capacity Dissolving Systems provide continuous supply of urea solution to flue gas treatment units, ensuring uninterrupted NOx control. Environmental Engineering Projects Municipal and industrial environmental engineering projects integrate Dissolving Systems into air pollution control infrastructures. These systems support compliance with environmental legislation and sustainable development goals. Advantages of Advanced Urea Dissolving Systems Implementing modern Dissolving Systems provides numerous operational advantages: Increased emission control efficiency Reduced chemical waste Lower maintenance costs Improved process automation Enhanced worker safety Long equipment lifespan Energy-efficient mixing technologies and smart automation reduce overall operational costs. Additionally, advanced monitoring systems in Dissolving Systems provide predictive maintenance data, minimizing unexpected breakdowns. By ensuring consistent solution quality, Dissolving Systems protect downstream SCR components from clogging and scaling issues. Design Considerations for Urea Dissolving Systems When selecting or designing Dissolving Systems, several factors must be considered: Required daily production capacity Desired

AdBlue® Dissolving Machines for Continuous Production

The global demand for AdBlue® continues to grow as emission regulations become stricter across Europe, North America, and emerging markets. Industries that rely on diesel-powered vehicles and heavy equipment must ensure a stable and high-quality supply of AdBlue® to maintain compliance with environmental standards. At the heart of efficient production lies one essential system: AdBlue® Dissolving Machines. These advanced industrial units allow manufacturers and distributors to produce AdBlue® continuously, safely, and with consistent quality. In this comprehensive guide, we will explore how AdBlue® Dissolving Machines work, their technical components, industrial applications, and why investing in the right system can significantly improve operational efficiency. What Is an AdBlue® Dissolving Machine? AdBlue® Dissolving Machines are industrial systems designed to produce AdBlue® solution by dissolving high-purity urea in demineralized water under strictly controlled conditions. AdBlue® itself is a 32.5% high-purity urea solution used in Selective Catalytic Reduction (SCR) systems to reduce nitrogen oxide (NOx) emissions from diesel engines. The chemical concentration must be precise, and contamination must be avoided at all costs. This is where AdBlue® Dissolving Machines become indispensable. These machines are engineered to: Automatically dissolve solid urea Maintain precise temperature levels Ensure homogeneous mixing Filter impurities Transfer the finished solution into storage tanks Modern AdBlue® Dissolving Machines are fully automated and designed for continuous industrial production. They eliminate manual mixing errors and ensure compliance with ISO 22241 quality standards. How AdBlue® Dissolving Machines Work An AdBlue® dissolving machine is a fully automated industrial unit that dissolves urea, controls temperature, filters impurities, and transfers the solution into storage tanks. The working principle of AdBlue® Dissolving Machines involves several carefully controlled stages: Demineralized Water Preparation: The process begins with high-quality demineralized water. Since AdBlue® purity is critical, any mineral contamination can damage SCR systems. Advanced AdBlue® Dissolving Machines integrate water treatment or connect directly to deionized water systems. Automated Urea Feeding: Solid automotive-grade urea is fed into the mixing tank through an automated feeding system. In professional AdBlue® Dissolving Machines, screw conveyors or vacuum transfer systems ensure precise dosing without human contact. Temperature-Controlled Dissolution: Urea dissolves optimally at controlled temperatures. High-performance AdBlue® Dissolving Machines include heating elements and temperature sensors to maintain the ideal dissolution environment. Homogeneous Mixing: Industrial agitators inside the stainless steel tank provide uniform mixing. Proper circulation prevents sedimentation and guarantees a consistent 32.5% concentration. Filtration and Transfer: After dissolution, the solution passes through multi-stage filtration units before transferring to storage tanks or filling systems. This automated workflow makes AdBlue® Dissolving Machines the most reliable solution for large-scale AdBlue® production. Difference Between AdBlue® Dissolving Machines and Manual Systems While some small operations may attempt manual mixing methods, industrial production requires precision and repeatability. The difference between professional AdBlue® Dissolving Machines and manual systems is substantial. Feature Manual Systems AdBlue® Dissolving Machines Production Capacity Limited and labor-dependent High-capacity continuous or batch production Solution Stability Variable concentration Precise 32.5% concentration control Human Error High risk Minimized through automation Operating Cost Higher long-term labor cost Lower long-term operational cost Key Features of Dissolving Machines Technical Components High-quality Dissolving Machines typically include: Stainless steel mixing tanks Automated urea feeding systems Temperature-controlled dissolution units PLC-based automation systems Level sensors and conductivity monitoring CIP (Clean-in-Place) systems Safety alarms and emergency stops Data logging and remote monitoring These advanced components ensure durability, efficiency, and full compliance with international production standards. Where Are Dissolving Machines Used? Industrial and Commercial Usage Areas Truck Service Stations: On-site AdBlue® production reduces supplier dependency. Fleet Management Companies: Ensures cost control and supply security. Mining and Construction Sectors: Continuous AdBlue® supply for heavy-duty equipment. Industrial Chemical Facilities: Production and packaging for wholesale markets. The versatility of Dissolving Machines makes them suitable for both centralized production plants and decentralized industrial sites. Benefits of Using Atmosfer Makina Dissolving Machines Reliable Industrial Performance Choosing the right manufacturer is as important as selecting the right system. Atmosfer Makina specializes in industrial-grade Dissolving Machines engineered for long-term performance. Continuous production capability ISO 22241 compliance Energy-efficient heating and mixing systems Customizable capacity options Durable stainless steel construction Investing in Dissolving Machines provides full production control, cost predictability, improved product quality, reduced supply risks, and faster response to market demand. Maintenance and Operational Considerations To ensure long service life, Dissolving Machines require: Regular filter replacement Periodic tank cleaning Sensor calibration Inspection of heating elements PLC system updates Atmosfer Makina designs Dissolving Machines with easy maintenance access, simplifying routine service and minimizing downtime. Ready to Upgrade Your AdBlue® Production? If you are looking for a reliable, efficient, and fully automated solution for continuous AdBlue® production, Atmosfer Makina is your trusted industrial partner. Whether you operate a truck service station, manage a large fleet, or run a chemical production plant, investing in a professional dissolving system ensures stable production, reduced operating costs, and full compliance with ISO 22241 standards. Take control of your AdBlue® supply chain, improve product consistency, and future-proof your operations against growing market demand. Visit atmosfermakina.com to explore advanced industrial solutions and request a customized quote for your facility. Atmosfer Makina – Engineering Reliable Solutions for Continuous AdBlue® Production.

AdBlue® Production System for Industrial Applications

Global emission regulations have accelerated the adoption of SCR (Selective Catalytic Reduction) technology across transportation and industrial sectors. At the core of this technology lies AdBlue®, a urea-based solution that significantly reduces nitrogen oxide (NOx) emissions. To meet growing demand, many companies are shifting from purchasing ready-made AdBlue® to producing it internally using a reliable AdBlue® production system. An industrial AdBlue® production system enables controlled, on-site manufacturing of high-quality AdBlue, ensuring compliance, cost efficiency, and operational continuity. As emission standards become stricter and supply chain volatility increases, investing in a professional AdBlue® production system is no longer an option but a strategic necessity. What Are AdBlue® Dissolving Systems? AdBlue® dissolving systems are specialized industrial installations designed to produce AdBlue® by dissolving solid automotive-grade urea into demineralized water at an exact concentration of 32.5%. These systems form the backbone of any modern AdBlue® production system, especially for high-volume or mission-critical operations. Unlike manual or semi-automated methods, an industrial AdBlue® production system guarantees consistent quality, traceability, and compliance with ISO 22241 standards. This is particularly important for organizations operating vehicle fleets, logistics hubs, or industrial facilities where SCR performance directly impacts regulatory compliance. Definition and Working Principle of AdBlue® Dissolving Systems An AdBlue® dissolving system operates through a closed-loop, automated process. Solid urea is fed into a dissolution tank, where it is mixed with demineralized water under controlled temperature and agitation conditions. Sensors continuously monitor concentration, temperature, and conductivity to ensure the final solution meets required specifications. In a professional AdBlue® production system, every stage—from raw material intake to final storage—is engineered to prevent contamination and crystallization. Automated dosing systems calculate the exact urea-to-water ratio, while filtration units remove any undissolved particles. The result is a homogeneous, high-purity AdBlue® solution ready for immediate use. The reliability of the AdBlue® production system directly affects SCR catalyst efficiency. Even small deviations in concentration can reduce emission control performance or damage vehicle components, making precision engineering essential. Why AdBlue® Dissolving Systems Are Essential for SCR Technology SCR systems rely on a precise chemical reaction between AdBlue® and exhaust gases. This reaction converts harmful NOx emissions into harmless nitrogen and water vapor. Without a stable and high-quality AdBlue® supply, SCR systems cannot function effectively. A well-designed AdBlue® production system ensures stable AdBlue® quality by maintaining exact concentration and purity levels. It prevents urea crystallization, which can clog injectors and damage SCR components. By producing AdBlue® on-site, companies also gain full control over quality assurance processes. Additionally, an industrial AdBlue® production system improves overall SCR efficiency by delivering consistent fluid properties under all operating conditions. This leads to measurable reductions in NOx emissions and helps organizations meet both local and international environmental regulations. Industrial Advantages of AdBlue® Dissolving Systems The transition from externally supplied AdBlue® to an in-house AdBlue® production system offers multiple industrial advantages. Beyond regulatory compliance, these systems support operational resilience, scalability, and long-term cost optimization. An industrial-grade AdBlue® production system is designed for continuous operation, making it suitable for high-demand environments such as fleet depots, power plants, and large maintenance facilities. By eliminating dependency on third-party suppliers, businesses reduce exposure to price fluctuations and supply interruptions. Automation and Process Control Modern AdBlue® dissolving systems integrate advanced automation technologies to ensure repeatable and error-free production. Automated dosing, temperature regulation, and mixing cycles are standard features of a high-quality AdBlue® production system. Process control units monitor every parameter in real time, allowing operators to detect deviations before they impact product quality. This level of automation not only improves consistency but also reduces labor requirements and human error. A fully automated AdBlue® production system can be seamlessly integrated into existing industrial control infrastructures, supporting remote monitoring, data logging, and predictive maintenance strategies. Cost Efficiency and Operational Reliability From a financial perspective, producing AdBlue® internally delivers significant cost advantages over long-term procurement. Bulk urea sourcing combined with an efficient AdBlue® production system lowers per-liter production costs and stabilizes operating expenses. Operational reliability is another key benefit. On-site production eliminates delays caused by logistics issues or supplier shortages. For fleet operators and industrial plants, uninterrupted access to AdBlue® is critical to maintaining uptime and avoiding regulatory penalties. By investing in a durable AdBlue® production system, organizations also reduce waste, optimize resource usage, and extend the service life of SCR components. Applications of AdBlue® Dissolving Systems AdBlue® dissolving systems are used across a wide range of industries where diesel engines and SCR technology are present. The flexibility of a modular AdBlue® production system allows it to be tailored to different production volumes and operational requirements. From transportation to energy generation, these systems support emission compliance in diverse and demanding environments. Industries Using AdBlue®Dissolving Systems Heavy-duty vehicle fleets rely on a dependable AdBlue® production system to support daily operations without interruption. Logistics and transportation companies benefit from centralized AdBlue® manufacturing at depots, reducing refueling downtime. Industrial maintenance facilities use AdBlue® dissolving systems to service equipment and vehicles internally, maintaining quality control. Power generation plants with diesel-based backup systems also depend on an AdBlue® production system to meet emission limits during operation.In all these sectors, the ability to scale production according to demand makes the AdBlue® production system a strategic asset rather than a simple auxiliary installation. Why Choose Atmosfer Makina AdBlue® Dissolving Systems? Selecting the right technology partner is critical when investing in an AdBlue® production system. System design quality, component selection, and after-sales support directly influence long-term performance and return on investment. Atmosfer Makina focuses on engineering-driven solutions that meet industrial performance expectations while remaining flexible and user-friendly. Each AdBlue® production system is designed with efficiency, durability, and compliance in mind. Custom Engineering and Industrial Quality Atmosfer Makina develops high-efficiency AdBlue® dissolving systems tailored to specific operational needs. Whether for small-scale fleet operations or large industrial facilities, each AdBlue® production system is engineered to deliver consistent output with minimal maintenance. Industrial-grade materials, corrosion-resistant components, and robust automation architectures ensure long service life even under continuous operation. By prioritizing quality and system integrity, Atmosfer Makina helps clients achieve reliable AdBlue®

What is Diesel Exhaust Fluid (DEF)? Everything You Need to Know

What is Diesel Exhaust Fluid (DEF) is a critical component in modern diesel engine technology, designed to reduce harmful emissions and ensure compliance with strict environmental regulations. As emission standards become more demanding across the globe, DEF has evolved from a niche requirement into an everyday necessity for fleet operators, commercial vehicle owners, and even individual diesel car users. DEF, often abbreviated as DEF, is a non-toxic, colorless, and odorless solution used in Selective Catalytic Reduction (SCR) systems. Its primary role is to minimize nitrogen oxide (NOx) emissions produced during diesel combustion. Without DEF, modern diesel engines cannot meet Euro 6, EPA Tier 4, or similar emission standards. From trucks and buses to agricultural machinery and construction equipment, DEF plays a central role in sustainable transportation. Understanding what DEF is, how it works, and why quality matters can help you protect your engine, reduce operating costs, and stay compliant with regulations. In this comprehensive guide, you will learn everything you need to know about DEF, from its chemical composition to its practical benefits for modern diesel engines. In the world of modern diesel engines, Diesel Exhaust Fluid (DEF) has evolved from a niche requirement into an everyday necessity. Whether you are a fleet operator, a construction equipment owner, or a diesel car user, understanding DEF is critical for ensuring engine health and remaining compliant with strict environmental regulations like Euro 6 and EPA Tier 4. The Chemistry of DEF: What is DEF Fluid Made Of? DEF is composed of a precise and carefully controlled mixture of two simple ingredients: high-purity urea and deionized water. Specifically, DEF consists of 32.5% automotive-grade urea and 67.5% deionized water. This exact ratio is not arbitrary; it is scientifically optimized to ensure efficient chemical reactions within the SCR system. The urea used in DEF is not the same as agricultural fertilizer-grade urea. Automotive-grade urea must meet strict purity standards to prevent contamination, crystallization, or damage to sensitive SCR components. Even small impurities can reduce the effectiveness of DEF and cause long-term harm to the exhaust aftertreatment system. Deionized water is equally important in DEF production. Minerals, salts, or metals commonly found in tap water can interfere with the chemical stability of Diesel Exhaust Fluid. By using deionized water, manufacturers ensure that Diesel Exhaust Fluid remains stable across a wide range of temperatures and operating conditions. When DEF is injected into the exhaust stream, it undergoes thermal decomposition. The heat converts the urea into ammonia (NH₃), which then reacts with nitrogen oxides inside the SCR catalyst. This reaction transforms harmful NOx gases into harmless nitrogen and water vapor. Because Diesel Exhaust Fluid freezes at approximately -11°C (12°F), vehicles are equipped with DEF tank heaters. Freezing does not damage DEF, and once thawed, it continues to function normally without losing effectiveness. DEF is a non-toxic, colorless, and odorless solution essential for Selective Catalytic Reduction (SCR) systems. To ensure the chemical stability required for high-performance engines, high-quality DEF follows a precise formula: 32.5% Automotive-Grade Urea: Unlike agricultural urea, this is highly purified to prevent crystallization and SCR damage. 67.5% Deionized Water: The use of deionized water is crucial because minerals found in tap water can lead to system contamination. SEO Insight: Highlighting the 32.5% ratio and ISO 22241 standards helps your content rank for technical queries. How DEF Works in Your SCR System The Selective Catalytic Reduction system is the technological backbone that allows DEF to perform its emission-reducing function. In an SCR-equipped vehicle, Diesel Exhaust Fluid is stored in a dedicated tank separate from diesel fuel. It is never mixed with diesel and should never be added to the fuel tank. As exhaust gases flow through the exhaust system, sensors continuously monitor temperature and NOx levels. Based on this data, the engine control unit calculates the precise amount of DEF required. The fluid is then injected into the exhaust stream upstream of the SCR catalyst. Inside the SCR catalyst, the ammonia derived from DEF reacts selectively with nitrogen oxides. This selective reaction ensures that NOx emissions are reduced efficiently without affecting other exhaust gases. The end result is a significant reduction in pollutants, often by up to 90%. DEF consumption varies depending on engine size, load, and driving conditions.On average, Diesel Exhaust Fluid usage is approximately 2–5% of diesel fuel consumption. For fleet operators, understanding Diesel Exhaust Fluid consumption patterns helps with cost forecasting and maintenance planning. Modern vehicles are designed to alert drivers when Diesel Exhaust Fluid levels are low. Ignoring these warnings can lead to reduced engine power or even a no-start condition, as emission compliance is mandatory by law in many regions. The SCR system acts as the technological backbone of your engine’s emission control. Here is the step-by-step process: Monitoring: Sensors in the exhaust system track NOx levels and temperature. Injection: The engine control unit calculates and injects a precise amount of DEF into the exhaust stream. Chemical Reaction: The heat converts DEF into ammonia (NH₃), which reacts with nitrogen oxides inside the catalyst. Result: Harmful NOx gases are transformed into harmless nitrogen and water vapor, reducing pollutants by up to 90%. Why Modern Diesel Engines Require High-Quality Fluid Not all Diesel Exhaust Fluid is created equal. High-quality DEF must comply with international standards such as ISO 22241. These standards define purity requirements, storage guidelines, and testing methods to ensure consistent performance. Using substandard DEF can result in crystallization, clogged injectors, and damaged SCR catalysts. Repairs to SCR systems can be expensive, often costing far more than the savings gained from purchasing low-quality fluid. For this reason, investing in certified Diesel Exhaust Fluid is a cost-effective decision in the long run. High-quality DEF also ensures accurate dosing within the SCR system. Consistent chemical composition allows sensors and control units to function correctly, maintaining optimal emission reduction without overuse or underuse of the fluid. Storage and handling also play a vital role in DEF quality. DEF should be stored in sealed containers away from direct sunlight and extreme temperatures. Contamination from dirt, fuel,

On-Site AdBlue® Production: AUS32 & DEF Manufacturing Process

On-Site AdBlue® Production: AUS32 & DEF Manufacturing Process Client Case Study: Sustainable AdBlue® Production for the Energy Sector At Atmosfer Makina, we specialize in providing innovative solutions for critical industrial needs. Today, we’re highlighting a powerful client case study on how our AdBlue® manufacturing process transformed supply for a leading energy sector player. This demonstrates the significant advantages of on-site AdBlue® production, emphasizing our commitment to both environmental responsibility and operational efficiency. The energy sector, heavily reliant on diesel engines for generators and machinery, faces stringent NOx emission regulations. Selective Catalytic Reduction (SCR) systems are the standard solution, using AdBlue® (AUS32, DEF). Traditionally, securing a consistent and cost-effective AdBlue® supply, especially in remote energy operations, has presented logistical and financial hurdles, including high transport costs and supply chain vulnerabilities. Our client, a major energy producer, sought to overcome these challenges. They needed full control over their AdBlue® supply, guaranteed ISO 22241 quality, and a reduced environmental footprint. Atmosfer Makina delivered a customized, autonomous AdBlue® manufacturing facility for on-site production, proving the immense value of our turnkey solutions in the AdBlue® manufacturing process. Why On-Site AdBlue® Production is Environmentally and Economically Preferable On-site AdBlue® production through Atmosfer Makina’s solutions offers compelling environmental and economic advantages over conventional supply methods. Economically, the primary benefit is substantial cost savings. By producing AdBlue® at your facility using urea for DEF, you cut out expenses like freight, storage at third-party distribution centers, and reseller margins. Urea for DEF is a dry granular product, making it significantly cheaper and easier to transport and store in bulk than liquid AdBlue®. This, combined with bulk urea purchasing, delivers a rapid return on investment and sustained savings. Our automated processes also minimize labor costs, giving you greater budgetary control and insulating you from market volatility. Environmentally, on-site AdBlue® production greatly reduces your carbon footprint. Traditional supply chains involve extensive transportation of liquid AdBlue®, generating significant greenhouse gas emissions. By manufacturing on-site, you drastically reduce this transport, leading to lower carbon emissions and a greener operational profile. It also means less road congestion and reduced risk of transportation-related spills, enhancing overall environmental safety. Furthermore, on-site production ensures unparalleled supply security and independence. For critical energy operations, uninterrupted AdBlue® supply is vital. Our AdBlue® manufacturing facility mitigates disruption risks, allowing you to produce AdBlue® on demand, guaranteeing continuous supply regardless of external market or logistical challenges. Lastly, on-site AdBlue® production provides superior quality control. AdBlue® quality directly impacts SCR system performance. Our integrated quality assurance systems continuously monitor the AdBlue® manufacturing process to ensure strict adherence to the ISO 22241 standard. This guarantees consistently pure and correctly concentrated AUS32, protecting your assets and optimizing emission reduction. Key Components of the AdBlue® Manufacturing Facility An Atmosfer Makina AdBlue® manufacturing facility is a meticulously engineered, self-contained system comprised of essential key components designed for efficient, high-quality AdBlue® (AUS32, DEF) production from urea for DEF. Central to the facility is the Urea Storage and Feeding System, which safely stores and precisely delivers granular urea for DEF into the process. The Demineralized Water Production Unit employs advanced water treatment (like reverse osmosis) to create the high-purity water crucial for AdBlue®. An energy-efficient water heating option can optimize urea dissolution, especially in colder climates. The heart of the AdBlue® manufacturing process is the Mixing and Dissolution Reactor, where urea for DEF is thoroughly dissolved in demineralized water to achieve the precise 32.5% concentration. This process is fully automated with sensors monitoring parameters. Following dissolution, the Filtration System ensures final purity by removing impurities. We offer an enhanced urea filtration option for the highest purity demands. Finally, the Quality Control and Monitoring System continuously measures concentration, conductivity, and other parameters, governed by a PLC. This intelligent system ensures consistent ISO 22241 compliant quality, minimal errors, and comprehensive data logging for every batch of AUS32. Urea Dissolution: Process Flow and Automation The urea dissolution stage is fundamental in the AdBlue® manufacturing process. It converts solid urea for DEF into liquid AUS32. Our process flow prioritizes precision and advanced automation. The process begins with automated transfer of urea for DEF from storage into a mixing tank. Simultaneously, demineralized water (potentially heated via the energy-efficient water heating option to 25-40°C) is precisely dosed. This temperature range is crucial for rapid and complete urea dissolution, preventing crystallization. Specialized agitators ensure homogeneous mixing, while real-time temperature and conductivity sensors monitor the solution. Conductivity accurately indicates urea concentration as it dissolves. Our sophisticated automation system, driven by a central PLC, orchestrates this entire process. It receives sensor data to dynamically adjust dosing rates of urea for DEF and water, maintaining the exact 32.5% concentration for AdBlue®. This high level of automation eliminates manual variability, reduces errors, and guarantees consistent quality. Detailed logging of all parameters ensures traceability and quality assurance for every AUS32 batch. Advanced Monitoring and Filtration Technologies Atmosfer Makina’s commitment to top-tier AdBlue® (AUS32, DEF) relies on our advanced monitoring and filtration technologies. These are vital for ensuring every liter produced meets the stringent ISO 22241 quality standard. Advanced Monitoring: High-precision sensors continuously track urea concentration, temperature, pH, and electrical conductivity (a key indicator of purity and concentration). A sophisticated PLC uses this real-time data to make instant adjustments, ensuring consistent quality. Proactive diagnostics, alarms, and detailed data logging provide comprehensive oversight and traceability for continuous AdBlue® production. Advanced Filtration Technologies: Purity is critical to protect SCR systems. Our AdBlue® manufacturing facilities incorporate multi-stage filtration technologies to remove impurities from urea for DEF and water. This includes pre-filtration and fine filtration. We offer an enhanced urea filtration option for the absolute highest purity requirements, safeguarding sensitive SCR catalysts. These systems are designed for minimal maintenance and maximum efficiency. Storage, Loading, and Supervision of Finished AdBlue® Once AdBlue® manufacturing process is complete and quality-approved, efficient storage, loading, and supervision of finished AdBlue® are crucial. Atmosfer Makina provides integrated solutions for these post-production steps, ensuring product integrity and availability. Our storage tank options are specifically designed for AdBlue®, made from compatible materials

Atmosfer Makina AdBlue® Production Skid

Atmosfer Makina AdBlue® Production Skid AUS32 Production Skid Solutions At Atmosfer Makina, we understand the critical role AdBlue® (AUS32) plays in reducing harmful nitrogen oxide (NOx) emissions from diesel engines. As a leading solution provider, we’re proud to offer state-of-the-art AdBlue® production skid solutions designed to empower businesses with the capability to produce high-quality AUS32 on-site. This significantly reduces logistical complexities, ensures consistent supply, and offers substantial cost savings compared to traditional procurement methods. Our commitment is to deliver reliable, efficient, and user-friendly systems that meet the stringent demands of the market for Diesel Exhaust Fluid (DEF). The demand for AdBlue® is continuously growing due to increasingly strict emission regulations worldwide. Relying on external suppliers can expose businesses to supply chain vulnerabilities, fluctuating prices, and potential quality inconsistencies. Our AdBlue® production skid solutions directly address these challenges by providing a robust, autonomous manufacturing capability. These systems are ideal for various applications, including large fleet operators, logistics hubs, mining operations, marine vessels, and remote industrial sites, wherever there’s a consistent need for AdBlue®. By enabling on-site production, we help our clients achieve greater operational control and a more secure supply of this essential emission control fluid. Our expertise in chemical process engineering allows us to design and manufacture AdBlue® production plants that are both highly efficient and environmentally conscious. We focus on creating systems that convert urea for DEF – the primary raw material – into a precise 32.5% aqueous urea solution that fully complies with the ISO 22241 standard. This adherence to international quality standards is paramount, ensuring that the AdBlue® produced by our systems is suitable for all Selective Catalytic Reduction (SCR) systems, safeguarding engine performance and longevity. Capacities from 15m³/day to 150m³/day At Atmosfer Makina, we know that every client has unique AdBlue® production needs. That’s why our AUS32 production skid solutions are engineered to offer a wide range of capacities, catering to various scales of operation. We provide systems with capacities ranging from 15m³/day to an impressive 150m³/day. This flexibility allows our clients to select a system that precisely matches their current and projected AdBlue® consumption, ensuring optimal efficiency without over- or under-investment. Whether you operate a small to medium-sized fleet, a single industrial site with moderate consumption, or a large-scale distribution center requiring substantial daily volumes, we have an AdBlue® production solution tailored for you. Our smaller units, such as those with a capacity of 15m³/day, are perfect for initial ventures into self-production or for operations with steady, moderate demand. These compact systems integrate seamlessly into existing infrastructures, offering a quick return on investment. For larger operations, our higher capacity systems, reaching up to 150m³/day, provide the capability to meet the demands of extensive vehicle fleets, multiple industrial facilities, or even regional distribution networks. These larger units are designed for continuous, high-volume production, ensuring that even the most demanding AdBlue® requirements are met without interruption. This scalability means your investment in an Atmosfer Makina production system can grow with your business needs. Our engineering team works closely with clients to assess their specific requirements, considering factors like current AdBlue® consumption, future growth projections, available space, and logistical constraints. This detailed consultation ensures that the chosen AdBlue® production skid not only fits the immediate capacity needs but also provides a sustainable and adaptable solution for years to come. By offering such a wide array of capacities, Atmosfer Makina solidifies its position as a versatile and responsive partner in the AUS32 production market. Description The Atmosfer Makina AdBlue® Production Skid is a complete, self-contained system engineered for the efficient and precise manufacturing of high-quality AdBlue® (AUS32) from urea for DEF. Designed as a modular, ready-to-operate unit, our systems minimize on-site installation time and complexity, providing a genuine turnkey solution for your AdBlue® production needs. Each system is meticulously constructed and pre-assembled within a robust frame, ensuring all critical components are integrated and tested before shipment. This design philosophy dramatically reduces the need for extensive civil work or specialized on-site construction. Once delivered, the system requires only connections to water, power, and the urea for DEF supply to become fully operational. This “plug-and-play” capability makes our AdBlue® production skids exceptionally versatile and easy to deploy in various industrial and logistical environments. The core of our AdBlue® production process involves the precise mixing of high-purity urea for DEF granules with demineralized water. Our systems feature advanced dosing and mixing technologies to ensure the exact 32.5% urea concentration required for ISO 22241 compliance. Integrated filtration systems meticulously remove impurities, guaranteeing the final AdBlue® product is clean and safe for all SCR systems. Continuous monitoring by high-precision sensors ensures real-time quality control, allowing the system to automatically adjust parameters to maintain optimal production. Our systems are controlled by sophisticated Programmable Logic Controllers (PLCs) and feature intuitive Human-Machine Interfaces (HMIs). This automation ensures consistent operation, minimizes human intervention, and provides comprehensive data logging for traceability and performance analysis. Operators can easily monitor production status, manage recipes, and access historical data, simplifying daily operations and troubleshooting. Safety features are also built into the design, including emergency shut-offs and alarm systems, ensuring secure operation at all times. Benefits of Atmosfer Makina Solutions Choosing an Atmosfer Makina AdBlue® production skid brings a multitude of benefits to your operation, transforming how you manage your AdBlue® supply. We focus on delivering solutions that provide both immediate and long-term value, enhancing efficiency, reliability, and cost-effectiveness. Cost Efficiency and Savings: One of the most significant advantages of on-site AdBlue® production is the dramatic reduction in operational costs. By manufacturing your own AUS32 from urea for DEF, you eliminate expenses associated with purchasing pre-made AdBlue® from external suppliers, including transportation costs, delivery fees, and distributor margins. Furthermore, purchasing urea for DEF in bulk is generally more economical and logistically simpler than transporting liquid AdBlue®, leading to substantial long-term savings. Our efficient designs also minimize energy and water consumption, further contributing to cost reduction. Assured Quality Control (ISO 22241 Compliance): Maintaining the purity and precise concentration of AdBlue® is crucial for

Engine Oils for Diesel Engines: Do They Affect AdBlue Efficiency?

Engine Oils for Diesel Engines: Do They Affect AdBlue Efficiency? This article from Atmosfer Makina addresses a critical aspect of modern diesel engine maintenance: the significant influence of engine oils on AdBlue (Diesel Exhaust Fluid – DEF) efficiency. As specialists in comprehensive engine care solutions, we recognize the paramount importance of optimizing the efficiency and longevity of your industrial machinery and vehicle fleets. This discussion will elucidate how the selection of appropriate engine oil directly impacts AdBlue consumption and overall operational expenditures. Choosing the Right Oil for SCR-Equipped Diesel Engines Modern diesel engines represent advanced engineering, designed for robust performance with minimized environmental impact. A cornerstone of this design is the Selective Catalytic Reduction (SCR) system, which, in conjunction with AdBlue, converts noxious nitrogen oxides (NOx) into benign nitrogen and water. The operational efficacy of this sophisticated system is critically dependent on the chosen engine oil. At Atmosfer Makina, we emphasize that engine oils are not uniformly formulated, particularly concerning applications in SCR-equipped engines. Conventional engine oils, characterized by higher concentrations of Sulfated Ash, Phosphorus, and Sulfur (SAPS), can inadvertently compromise your SCR system’s performance. During the combustion process, byproducts of these elements can form deposits that foul the SCR catalyst. This accumulation reduces the catalyst’s ability to facilitate the chemical reaction between AdBlue and NOx. The consequence is a diminished NOx conversion efficiency, necessitating increased AdBlue injection to compensate and meet emission standards, thereby escalating operational costs. Consequently, Low-SAPS engine oils are not merely recommended but are an essential requirement for machinery and vehicles incorporating SCR technology. These oils are meticulously engineered to contain minimal levels of the aforementioned detrimental elements. The application of Low-SAPS oils actively safeguards your SCR catalyst from premature degradation and contamination. This ensures the catalyst’s sustained cleanliness and full functionality, allowing the SCR system to operate at its peak efficiency. The result is optimized AdBlue utilization, leading to effective NOx reduction with reduced fluid consumption. Selecting the appropriate Low-SAPS oil, available through Atmosfer Makina, constitutes a strategic investment in the longevity of your emissions systems, sustained compliance, and significant control over fuel and AdBlue expenses. It represents a commitment to sustainable performance and long-term economic benefits. How AdBlue and Engine Oil Work Together While AdBlue and engine oil fulfill distinct functions within a diesel engine, their interaction is more integrated than commonly perceived, particularly in the context of emissions control and system durability. AdBlue, a high-purity urea solution, is fundamental to the SCR system. It is precisely metered into the exhaust stream, where it reacts on the SCR catalyst to transform harmful NOx emissions into inert nitrogen gas and water vapor. This process is indispensable for adherence to stringent environmental regulations. The critical nexus between AdBlue and engine oil pertains to the preservation of the SCR catalyst’s integrity. As previously indicated, traditional engine oils with elevated SAPS levels generate ash and other residues during combustion. These byproducts can traverse with the exhaust gases and accumulate on the sensitive surfaces of the SCR catalyst. Over time, these deposits can coat the catalyst, effectively diminishing its reactive surface area and impeding its capacity to efficiently facilitate the NOx conversion process. When the catalyst’s efficiency is compromised, the engine’s control unit compensates by injecting a greater volume of AdBlue to attain the mandated NOx reduction levels, resulting in elevated AdBlue consumption and increased operational expenditures. Conversely, the deployment of Low-SAPS engine oils, which we proudly offer at Atmosfer Makina, directly supports the optimal function of your SCR system. By minimizing the formation of catalyst-fouling deposits, these advanced lubricants ensure the SCR catalyst remains clean and highly reactive. This facilitates AdBlue’s efficient role, maximizing NOx conversion with the intended fluid volume. Our specialized range of Low-SAPS lubricants is engineered for seamless integration with your engine’s emissions control system, fostering a synergistic relationship between the engine oil and AdBlue. This synergy not only curtails AdBlue expenditure but also prolongs the operational life of costly SCR components, yielding substantial long-term savings and enhanced reliability. Comprehending and optimizing this critical partnership ensures that your diesel engines operate more cleanly, efficiently, and economically. Tips for Reducing Maintenance Costs Effective reduction of maintenance costs for diesel engines is a strategic imperative that transcends mere repair; it involves proactive measures and informed decision-making. At Atmosfer Makina, we provide our clients with solutions that contribute to substantial long-term savings. Our principal recommendations include: Prioritize Scheduled Maintenance with Quality Consumables: Adherence to the manufacturer’s prescribed service intervals is mandatory. However, the quality of consumables utilized during these services is equally vital. The deployment of substandard filters or fluids can precipitate premature wear and unforeseen operational failures. Investing in high-quality engine oils, such as the specialized Low-SAPS options from Atmosfer Makina, and genuine replacement parts ensures optimal performance and extended service life. Select Appropriate Lubricants: As previously elaborated, the correct engine oil is paramount. For SCR-equipped engines, invariably select Low-SAPS oils to safeguard your SCR system and optimize AdBlue efficiency. The use of incorrect oil can lead to expensive catalyst replacements and elevated AdBlue consumption. Our experts at Atmosfer Makina are available to assist in selecting the precise lubricant for your specific engine model and operational demands, ensuring compliance and peak performance. Maintain Consistent Fluid Level and Quality Monitoring: Regular assessment of engine oil, coolant, and AdBlue levels and quality can preempt minor issues from escalating into major, costly failures. Contaminated or insufficient fluids can lead to overheating, increased friction, and systemic malfunctions. Early detection of these issues provides both time and cost savings. Implement Proactive Diagnostics: Avoid waiting for a breakdown event. The utilization of diagnostic tools and services can identify potential issues before they manifest as critical failures. This enables planned, rather than reactive, maintenance, often at a reduced cost. Atmosfer Makina offers comprehensive diagnostic support to maintain uninterrupted operations. Ensure Thorough Operator and Maintenance Personnel Training: A well-informed team constitutes your primary defense against preventable wear and tear. Adherence to proper operating techniques and maintenance protocols can significantly extend engine lifespan and reduce

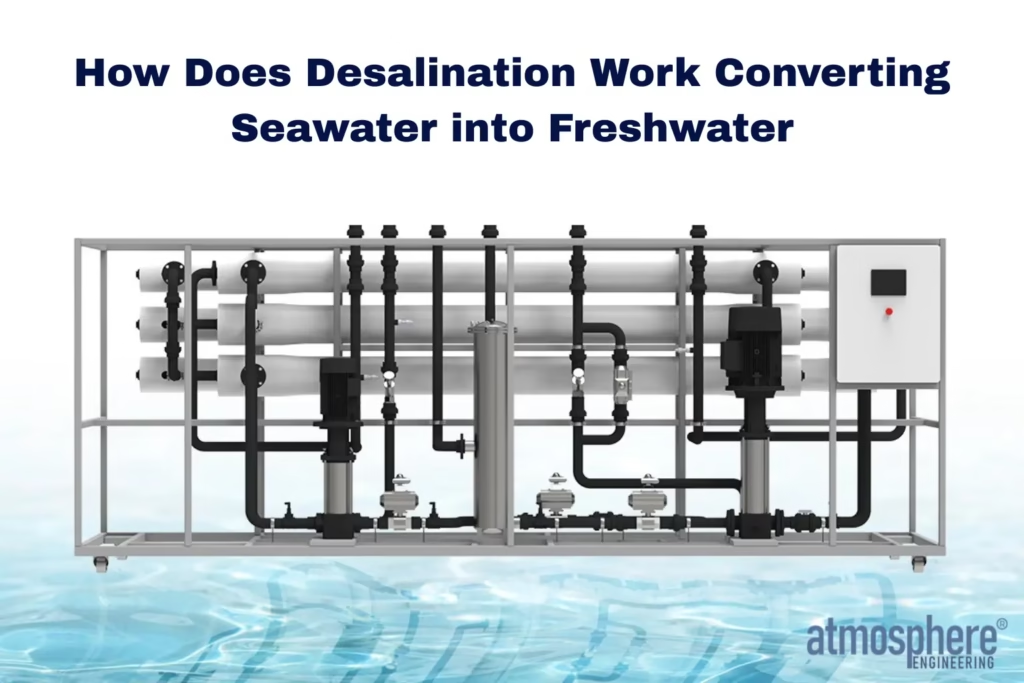

How Desalination Works: Converting Seawater into Freshwater

How Desalination Works: Converting Seawater into Freshwater A New Horizon in Water Solutions: Reverse Osmosis by Atmosfer Makina At Atmosfer Makina, we are at the forefront of tackling one of the most pressing global challenges: water scarcity. As a company dedicated to innovative engineering and sustainable solutions, we understand that access to fresh, clean water is not just a utility, but a fundamental human right and a cornerstone of economic development. While over 70% of our planet is covered by water, less than 1% is readily available freshwater. This is where Reverse Osmosis (RO), the most advanced and efficient method of converting saline or brackish water into potable water, becomes indispensable. Through our cutting-edge RO water treatment systems and unwavering commitment, Atmosfer Makina is proud to provide robust and efficient solutions that transform this abundant resource into a viable answer for communities, industries, and agriculture worldwide. For decades, the concept of turning challenging water sources into clean, usable water seemed complex. Today, thanks to relentless innovation and technological advancements in Reverse Osmosis technology, it is a reality, and Atmosfer Makina is playing a crucial role in making it more accessible, efficient, and sustainable than ever before. Join us as we delve into the intricate world of RO desalination, exploring how it works, the diverse applications it serves, and the immense benefits and critical considerations that shape its future. Overview of Reverse Osmosis Technology: The Modern Marvel of Water Purification The journey from saline or brackish water to crystal-clear drinking water is achieved primarily through the sophisticated process of Reverse Osmosis. At Atmosfer Makina, we specialize in implementing and optimizing the most effective RO systems, each meticulously designed for specific needs and conditions. Reverse Osmosis (RO): The Core of Our Water Purification Systems Reverse Osmosis stands as the most widely adopted and energy-efficient desalination and water purification technology globally, and it is the cornerstone of Atmosfer Makina’s offerings. The principle behind RO is elegantly simple yet incredibly powerful. Imagine a semi-permeable membrane, a barrier that allows water molecules to pass through but blocks larger salt ions, dissolved solids, bacteria, viruses, and other impurities. In natural osmosis, water flows from a region of lower solute concentration to a region of higher solute concentration across such a membrane to equalize the solute levels. Reverse osmosis, as its name suggests, reverses this natural process. Here’s how it works in our systems: Seawater, brackish water, or even wastewater is subjected to immense pressure – far exceeding its natural osmotic pressure – on one side of a semi-permeable membrane. This applied pressure forces water molecules through the membrane, leaving behind dissolved salts, minerals, bacteria, viruses, and other contaminants on the pressurized side. The result is purified freshwater (permeate) on one side and a concentrated brine solution (reject water) on the other. Atmosfer Makina’s RO systems are engineered for maximum efficiency and longevity. We integrate high-quality membranes, advanced energy recovery devices, and sophisticated pre-treatment systems. Pre-treatment is a critical step in RO, as it protects the delicate membranes from fouling and scaling by removing suspended solids, organic matter, chlorine, and other particulate impurities. Our robust pre-treatment solutions, which can include multi-media filters, activated carbon filters, softeners, and antiscalant dosing, ensure the membranes operate optimally, extending their lifespan and reducing operational costs. The continuous innovation in membrane technology and energy recovery has significantly reduced the energy consumption of RO, making it an increasingly attractive and sustainable option for large-scale water production. Our expertise encompasses a range of specialized RO systems: Commercial and Industrial RO Systems: Tailored for various industries requiring specific water quality, from manufacturing to power generation. Seawater Reverse Osmosis (SWRO) Systems: Robust solutions designed to handle high salinity seawater for municipal and industrial applications. Brackish Water Reverse Osmosis (BWRO) Systems: Efficiently convert brackish groundwater into potable water. Chemical Dosing Systems: Essential for pre-treatment (antiscalants, coagulants, pH adjustment) and post-treatment (disinfection). Atmosfer Makina prides itself on delivering comprehensive RO solutions that meet the highest standards of water quality and operational reliability. Applications and Benefits of Reverse Osmosis Water Treatment While the promise of RO technology is immense, Atmosfer Makina approaches its implementation with a clear understanding of both its significant advantages and the challenges that require careful consideration and innovative solutions. The Overwhelming Benefits of RO Systems Addressing Water Scarcity: RO provides a reliable, drought-proof source of freshwater, especially in arid regions and coastal urban centers. Economic Development and Stability: RO systems support industrial expansion, agricultural productivity, and tourism, fostering job creation and enhancing economic stability. Exceptional Water Quality: RO produces water of exceptionally high purity, ideal for drinking, sensitive industrial processes, and even pharmaceutical production. Versatility in Feedwater: RO systems can treat seawater, brackish water, surface water, and even wastewater for reuse. Reduced Chemical Usage: RO often requires fewer chemicals, especially with effective pre-treatment. Navigating the Considerations Energy Consumption: Modern RO is more energy-efficient, but still a key consideration. Atmosfer Makina integrates energy recovery devices and explores renewable energy sources. Brine Management: Atmosfer Makina employs advanced brine discharge strategies and explores beneficial uses for brine. Pre-treatment Importance: Investing in robust pre-treatment solutions is crucial. Capital and Operational Costs: Atmosfer Makina focuses on optimizing design and implementing efficient strategies. Cost-Efficiency and Energy Consumption Considerations for RO Systems At Atmosfer Makina, we understand that cost-efficiency and energy consumption are paramount. Our philosophy delivers technologically advanced, economically viable, and environmentally responsible RO solutions. Optimizing Cost-Efficiency of RO Plants CAPEX Optimization: Smart design, strategic sourcing, and excellent project management. OPEX Reduction: Energy efficiency, automation, preventive maintenance, and optimized chemical dosing. Energy Consumption: A Core Focus for Sustainable RO Modern RO plants are remarkably energy-efficient, thanks to: High-Efficiency RO Membranes Energy Recovery Devices (ERDs) Integration with Renewable Energy Reverse Osmosis Water Treatment Projects by Atmosfer Makina Atmosfer Makina stands as a testament to engineering excellence in RO water treatment. Our projects deliver tailored, high-performance solutions, characterized by: Customized RO System Design Robust Construction Advanced Automation and Control Sustainable Practices Comprehensive Support From consultation to operational support, Atmosfer Makina offers a

Industrial Water Purification Systems: A Comprehensive Guide

Industrial Water Purification Systems: A Comprehensive Guide At Atmosfer Makina, we know that water is far more than a utility—it’s the lifeblood of modern industry. Whether you’re operating a power plant, a food processing facility, or a chemical production line, water quality plays a pivotal role in everything from product safety to system longevity. As experts in water purification, we design and deliver custom reverse osmosis (RO) systems tailored to the rigorous demands of industrial operations. In this guide, we’ll walk you through the key technologies, target industries, system components, and our turnkey project approach. Types of Water Purification Technologies (RO, UF, EDI) Water purification is not a one-size-fits-all process. Depending on your industry and water source, your system may require different levels of filtration and demineralization. At Atmosfer Makina, we offer advanced water purification solutions based primarily on Reverse Osmosis (RO), but we also integrate Ultrafiltration (UF) and Electrodeionization (EDI) technologies where needed. Reverse Osmosis (RO) RO is the backbone of industrial water purification. It works by applying pressure to push water through a semi-permeable membrane that removes up to 99% of dissolved salts, bacteria, viruses, and other contaminants. This method is ideal for industries requiring consistently high-quality water such as energy, pharmaceuticals, and manufacturing. We offer several RO models under our premium lines: ELITE Series – Designed for seawater desalination applications. PLATINUM Series – Optimized for high-volume, land-based facilities. OCEAN Series – Engineered for compact marine and mobile systems. Ultrafiltration (UF) UF is often used as a pre-treatment step before RO, especially when the raw water contains large particles or biological contaminants. It removes suspended solids, colloids, and some bacteria, thereby extending the life of downstream RO membranes. Electrodeionization (EDI) EDI is used post-RO to achieve ultrapure water levels without chemicals. It uses ion exchange membranes and electrical current to continuously deionize water. This is ideal for high-purity applications like electronics manufacturing or boiler feedwater in power plants. Which Industries Use Advanced Water Treatment Systems? Industries across the board depend on clean, consistent water. Here are the sectors we serve with our industrial-grade purification systems: Energy & Power Generation Boilers and turbines require water that is free of minerals and ions to prevent corrosion and scaling. Our RO and EDI systems produce ultra-clean water that protects your infrastructure and boosts thermal efficiency. Pharmaceutical & Biotech In these sectors, compliance with USP and EP standards is critical. Our systems ensure water is pure enough for injections, ingredient formulation, and sterile cleaning. Food & Beverage From bottled water to dairy processing, water impacts taste, safety, and product consistency. Our systems remove off-flavors, contaminants, and pathogens to meet food-grade quality. Chemical & Petrochemical Our RO solutions support chemical processes that require stable water chemistry, minimizing the risk of contamination or undesired reactions. Electronics & Semiconductor This industry demands ultrapure water (UPW) with resistivity levels up to 18 MΩ·cm. Our RO + EDI systems meet this strict requirement, ensuring clean circuits and high product yield. Marine & Offshore For ships, offshore rigs, and remote units, water purification must be compact, durable, and efficient. Our OCEAN series RO systems deliver reliable desalination under the harshest conditions. Main Components of a High-Efficiency Purification Setup A well-designed purification system is more than just a membrane. It is a coordinated set of components, working seamlessly together. Pre-Treatment Units These units remove large debris, chlorine, and hardness that could damage sensitive RO membranes. They may include: Multimedia filters Activated carbon filters Water softeners High-Pressure Pumps Our systems use robust high-pressure pumps to drive water through RO membranes efficiently. Selecting the right pump ensures optimal energy use and membrane life. Reverse Osmosis Modules The heart of the system. Our RO units feature spiral-wound membranes designed to reject a wide spectrum of dissolved impurities, from salts to organic materials. Ultrafiltration Modules (optional) When required, UF modules are used upstream of RO to remove bacteria, algae, and suspended solids. Electrodeionization Units (optional) For industries that need chemical-free, ultrapure water, we integrate EDI after RO. This setup allows continuous operation and low maintenance. PLC-Controlled Automation Systems Every Atmosfer Makina system includes a user-friendly control panel equipped with: Real-time conductivity, flow, and pH monitoring Fault alerts Auto start/stop and CIP functions Skid-Mounted Compact Design Our systems are delivered ready-to-install, minimizing onsite work. Each unit is factory-tested and built with space efficiency in mind. Turnkey Projects by Atmosfer Makina Our expertise goes beyond components. We offer complete turnkey water purification projects, tailored to your unique needs. Step 1: Consultation & Water Analysis We assess your raw water quality, operating environment, and industry standards. Based on this, we select and size every component of your system. Step 2: Custom Engineering We design and model your purification setup using advanced simulation tools. All components are carefully selected for maximum durability and compatibility. Step 3: Manufacturing & Testing Your system is built in our facility and undergoes rigorous quality control testing before shipment. Step 4: Installation & Commissioning Our technicians install the system on your site, integrate it with existing utilities, and ensure it’s fully operational from day one. Step 5: Training & After-Sales Support We train your staff to operate and maintain the system. Our support team is always available for technical assistance and spare parts. Frequently Asked Questions (FAQ) How does reverse osmosis actually work in industrial settings? ➡️ RO uses pressure to force water through a membrane, filtering out salts, minerals, and microbes. The result is purified water suitable for industrial applications. What industries benefit the most from Atmosfer Makina’s RO systems? ➡️ Energy, pharma, F&B, chemicals, electronics, and marine industries all benefit significantly from our high-efficiency RO setups. Do you offer systems for seawater desalination? ➡️ Yes. Our ELITE and OCEAN series are designed specifically for seawater and high-salinity sources. Can I use your RO system in a pharmaceutical-grade process? ➡️ Absolutely. We comply with USP and EP water quality standards and offer systems compatible with sterile environments. What is the lifespan of your RO membranes? ➡️ With proper pre-treatment and

Zero Waste Strategies in Industrial Production: Protecting Cost and the Environment

Zero Waste Strategies in Industrial Production: Protecting Cost and the Environment Welcome to Atmosfer Makina, where we believe that profitability and sustainability are not just compatible—they are mutually dependent. In today’s competitive global market, the pressure is on industrial manufacturers to be both highly efficient and environmentally responsible. This dual challenge requires more than just minor adjustments; it demands a fundamental shift toward a Zero Waste strategy. As a leader in designing and implementing advanced industrial machinery and complete production line solutions, we have witnessed how embracing waste reduction technologies transforms a factory floor. A Zero Waste approach is no longer a niche environmental movement; it is a powerful business model that directly impacts your bottom line by minimizing material input, optimizing processes, and unlocking hidden value from waste streams. At Atmosfer Makina, our expertise extends beyond simply building reliable machines; we engineer sustainable production systems that integrate resource efficiency into every step, from material handling to final packaging. We invite you to explore how modern industrial waste management and circular economy principles can revolutionize your operations, secure cost savings, and position your company as a leader in sustainable manufacturing. The Foundation of Efficiency: Waste Reduction and Resource Recovery Achieving a Zero Waste manufacturing facility begins with a comprehensive strategy focusing on two key areas: aggressive waste minimization at the source and the implementation of intelligent resource recovery models. Waste Reduction and Recycling Models The core principle of Zero Waste is simple: waste is a resource out of place. The most effective way to manage waste is to prevent it from being generated in the first place. This is where Atmosfer Makina’s precision machinery plays a crucial role. Precision Engineering for Source Reduction: In production lines (especially in filling, packaging, and chemical processes), a significant portion of waste comes from inaccuracies—overfilling, rejected packaging due to misalignment, and product spillage. Our high-accuracy filling machines and integrated quality control systems (like vision inspection and check-weighers) ensure that every unit is filled and packaged perfectly the first time. This source reduction minimizes the use of raw materials and slashes costly disposal fees. Internal Closed-Loop Recycling Systems: For inevitable process by-products, a modern factory must implement closed-loop recycling. This means waste generated in one part of the plant becomes a raw material for another. For example, in liquid processing, residual product in pipes or cleaning water can be recovered, treated (using our specialized filtration or distillation units), and safely re-introduced into the production stream. This material recycling minimizes the need for virgin materials and reduces reliance on external, often costly, waste disposal companies. Optimal Packaging Design and Materials: Beyond the process, we consult on sustainable packaging strategies. This includes advising on machinery capable of handling recycled content packaging (like recycled PET or rHDPE) and minimizing the packaging footprint (e.g., lightweighting or optimizing container shapes). Our labelling and capping machines are calibrated to handle these new eco-friendly materials without compromising line speed or integrity. Waste recycling should start with the package itself. By combining manufacturing precision with smart material flow management, we help clients transform from a linear “take-make-dispose” model to a truly circular manufacturing process. Energy and Heat Recovery Beyond material waste, the other major source of inefficiency in industrial production is energy waste, often lost as heat, compressed air leakage, or inefficient motor usage. Zero Waste extends to maximizing energy efficiency and implementing heat recovery systems. Optimized Machine Efficiency: All Atmosfer Makina machinery is designed with energy efficiency as a core standard. We utilize high-efficiency motors (IE4) and variable frequency drives (VFDs) on conveyors and pumps. VFDs adjust motor speed based on the real-time load, drastically cutting energy consumption compared to traditional motors that run at a constant, unnecessary maximum speed. This focus on operational energy optimization directly reduces your utility bills and carbon footprint. Industrial Heat Recovery Systems: In many industrial processes—especially those involving drying, sterilization, or chemical reactions—a large amount of heat is generated and typically vented into the atmosphere. This is wasted money. We integrate heat exchangers and thermal energy recovery systems that capture this waste heat. This captured energy can then be used to pre-heat boiler feed water, warm up process chemicals, or even heat the factory floor in winter. This process efficiency can offset a significant percentage of a facility’s heating energy needs, leading to monumental cost savings and making your production genuinely sustainable. Smart Monitoring and Control: Our advanced control systems (HMI and SCADA integration) are key to managing energy consumption. They provide real-time data on the energy usage of every component, allowing operators to identify and eliminate energy-wasting bottlenecks or non-productive running periods. This data-driven resource efficiency ensures that every Joule is used optimally. Implementing these energy management and waste minimization strategies moves a facility far beyond simple compliance and into the realm of economic and environmental leadership. Zero Waste in Practice: Optimization and Innovation The ultimate goal of a Zero Waste strategy is to integrate sustainability into the fabric of the manufacturing plant, turning philosophical commitments into concrete, measurable actions. This requires moving from concepts to specific, replicable production examples and optimizing every phase of resource use. Real-World Zero Waste Production Examples The theory of industrial sustainability comes alive when applied to specific industry challenges. Atmosfer Makina has supported clients in diverse sectors to achieve measurable Zero Waste success: Chemical & Detergent Production: Chemical processing often leaves residual product in tanks and lines. We implement pigging systems and specialized product recovery machinery that pushes virtually all of the high-value chemical out of the pipe before cleaning, maximizing yield and minimizing the amount of contaminated wastewater that requires costly treatment. This turns potential hazardous waste into valuable saleable product. Beverage and Food Processing: In bottling operations, rejected bottles (due to minor imperfections or filling errors) are common. Our systems use advanced sorting and de-capping mechanisms to automatically recover the liquid product from the rejected containers, which is then filtered and re-introduced into the batch, while the packaging material (glass, plastic, aluminum) is sorted for high-grade