The Defining Factor in AdBlue® Production: Urea Purity

The Defining Factor in AdBlue® Production: Urea Purity At Atmosfer Makina, we understand that in the world of modern diesel engines, AdBlue® is not just a fluid; it’s a critical component for environmental compliance and operational efficiency. The effectiveness of any Selective Catalytic Reduction (SCR) system—and by extension, the performance of your entire vehicle or fleet—hinges on the quality of the AdBlue® you use. And at the heart of that quality lies a single, non-negotiable factor: urea purity. Our commitment to this principle is what drives our work. We see countless examples where producers, in an effort to cut costs, compromise on their raw materials. But as a leading provider of AdBlue® production systems and high-purity urea, we are here to tell you that this is a critical mistake with severe, long-term consequences. In this article, we’ll explore why urea purity is the cornerstone of quality AdBlue®, the risks of using substandard materials, and how our “Prilled Urea Without UF” solution stands as the ultimate safeguard for your production and your customers’ vehicles. The Impact of Impure Urea on the Production Process When we talk about impurities, we’re not just referring to visible dirt or debris. We are talking about trace elements—metals, aldehydes, biuret, and other compounds—that are found in agricultural-grade urea. While these are harmless in a fertilizer, they are highly destructive when introduced into a sophisticated chemical process like AdBlue® production. The moment impure urea is used, the integrity of the entire production line is compromised. These contaminants can cause immediate issues, such as fouling of filters and nozzles, leading to decreased flow rates and production inefficiencies. Over time, these minor irritations escalate into major problems, including irreversible damage to sensitive equipment. This translates directly into higher maintenance costs, increased downtime, and a significant drop in your overall production yield. The promise of short-term savings from using cheaper, impure urea quickly evaporates when faced with the reality of expensive repairs and operational disruptions. Atmosfer Makina’s “Prilled Urea Without UF” Solution Recognizing the widespread problem of urea contamination, we at Atmosfer Makina developed a solution that sets a new standard for the industry: our “Prilled Urea Without UF.” This product is not merely a component; it is a guarantee of quality and compliance. We have engineered a urea that is ultra-pure, specifically manufactured for the sole purpose of AdBlue® production. Our “Prilled Urea Without UF” is completely free from UF (urea-formaldehyde) coatings and other additives commonly found in agricultural-grade urea. This is a crucial distinction. These coatings can react with the deionized water used in AdBlue® production, creating harmful by-products that fail to meet the strict ISO 22241 standards. Our product’s exceptional purity ensures a stable, clean chemical reaction, resulting in a final product that consistently surpasses the required quality benchmarks. By choosing our urea, you are not just buying a raw material; you are investing in reliability, consistency, and peace of mind. Our prilled form factor ensures rapid dissolution, streamlining your production process and reducing energy consumption. This makes your operation not only more reliable but also more efficient. With Atmosfer Makina, you are equipped with the foundational ingredient for producing a superior, ISO-certified AdBlue® that protects your brand and the engines it serves. The Dangers of Contaminants to SCR Systems The damage from impure urea extends far beyond your production facility—it directly impacts your customers and their vehicles. The SCR system is a highly sensitive and sophisticated piece of technology. It relies on a precise reaction between AdBlue® and exhaust gases to convert harmful nitrogen oxides (NOx) into harmless nitrogen and water vapor. When AdBlue® made from impure urea is used, the contaminants can have devastating effects. The most common issues include: Crystallization and Blockage: Impurities can form crystals and deposits within the SCR system, clogging the injector nozzle, the dosing unit, and even the catalyst itself. This leads to a severe reduction in performance and, in many cases, complete system failure. Sensor Malfunction: The sensitive NOx sensors, crucial for monitoring the SCR system’s performance, can become coated or poisoned by contaminants, leading to inaccurate readings and triggering false warning lights on the vehicle’s dashboard. Catalyst Degradation: Over time, impurities can poison the catalyst, rendering it ineffective. This irreversible damage means the SCR system can no longer properly reduce emissions, leading to a failure of emission tests and potentially costly catalyst replacement. Ultimately, the use of low-quality AdBlue® can void vehicle warranties, lead to expensive repairs, and cause significant downtime for vehicle operators. The reputation of the AdBlue® producer is directly tied to the performance and reliability of their product in the field. H3: The Effect on Operating Costs and Reliability The true cost of using impure urea goes far beyond the initial purchase price. For the AdBlue® producer, the long-term impact on profitability and brand reputation is immense. Imagine the cost of dealing with customer complaints, warranty claims, and the logistical nightmare of a product recall. These hidden costs can quickly erase any perceived savings from using cheaper raw materials. Our “Prilled Urea Without UF” is a strategic investment in your business’s long-term health. By using a product that guarantees ISO 22241 compliance and protects against costly SCR system failures, you can build a reputation for reliability and quality. This confidence allows you to secure larger contracts, attract more loyal customers, and differentiate yourself in a competitive market. Furthermore, a stable production process with minimal downtime and maintenance reduces your operational costs and increases your profitability. With Atmosfer Makina, you are not just selling AdBlue®; you are selling trust, performance, and peace of mind. Frequently Asked Questions Q1: Why can’t I just use agricultural urea for my AdBlue® production? A1: Agricultural urea contains impurities like aldehydes, heavy metals, and biuret that are not harmful to plants but are highly corrosive and damaging to SCR systems. Our “Prilled Urea Without UF” is specifically manufactured to be ultra-pure, meeting the stringent ISO 22241 standards to ensure the longevity and performance of vehicles. Q2: How does your Prilled

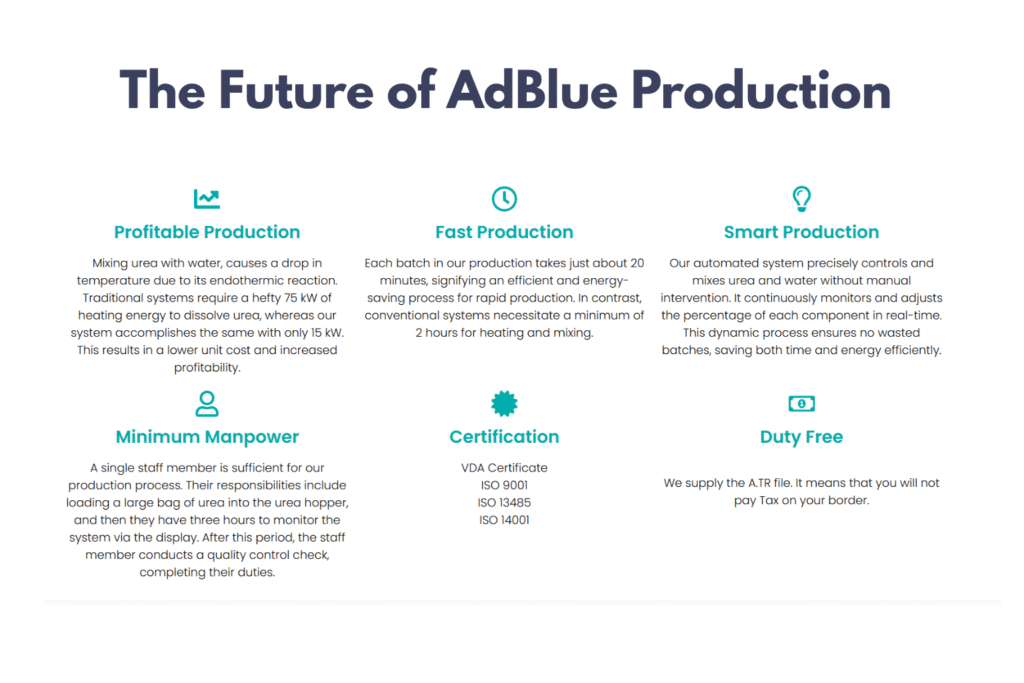

Energy Efficiency in AdBlue Production Plants Through Smart Automation

Energy Efficiency in AdBlue Production Plants Through Smart Automation At Atmosfer Makina, we understand that the production of Diesel Exhaust Fluid (DEF)—commonly known as AdBlue—is a mission-critical process. It is a fundamental component of the global effort to reduce NOx emissions and comply with stringent environmental standards like Euro V and VI. However, achieving high-volume production while maintaining impeccable ISO 22241 quality standards often comes at a significant energy cost. The modern industrial landscape demands not only efficiency but also sustainability. As a leader in AdBlue Production Plant technology, Atmosfer Makina is constantly innovating to meet these dual demands. Our answer lies in the integration of Smart Automation and Artificial Intelligence (AI), transforming traditional manufacturing lines into optimized, energy-efficient, and future-proof systems. This post delves into how our proprietary Smart Control Systems are revolutionizing the AdBlue Manufacturing process, ensuring compliance, minimizing waste, and maximizing Energy Efficiency from the blending tank to the final packaging stage. The Automation Revolution: From Simple Control to Smart Production For decades, the AdBlue manufacturing process relied on conventional Process Optimization techniques. While effective, these methods lacked the granular control and predictive capabilities necessary for true excellence in efficiency and quality. Atmosfer Makina’s vision moves beyond basic mechanization into a world of truly Automated AdBlue production. The Rise of Automation and Smart Control Systems The core of any efficient AdBlue Production Plant is precision. AdBlue is a highly sensitive, high-purity Urea Solution (32.5% urea in demineralized water) whose concentration must be maintained with absolute fidelity. Deviations can lead to catastrophic damage to SCR (Selective Catalytic Reduction) systems in vehicles. Our Smart Control Systems leverage state-of-the-art Programmable Logic Controllers (PLCs) and sophisticated SCADA (Supervisory Control and Data Acquisition) infrastructure. This allows for closed-loop control that monitors critical parameters—temperature, pressure, blending ratios, water purity, and energy consumption—in real-time. Dynamic Blending Technology: Traditional systems operate on fixed parameters. Our Smart Control Systems, however, employ dynamic blending algorithms. If, for instance, the ambient temperature shifts, potentially affecting the dissolution rate, the system automatically adjusts the mixing speed and heating element usage instantaneously. This prevents over-processing, reduces cycle time, and significantly lowers the power draw from major energy-consuming components like pumps and heaters, delivering crucial Energy Efficiency. Harmonic Power Management: In large-scale DEF Manufacturing operations, motors and pumps constitute a major energy load. Our automation integrates Variable Frequency Drives (VFDs), not just to control speed, but to ensure that motors operate at their peak energy efficiency point, minimizing reactive power loss. The Smart Control System anticipates flow requirements and scales power consumption accordingly, optimizing the entire electrical footprint of the AdBlue Plant. The resulting effect is not merely automation, but intelligent, adaptive production. This level of granular control is the foundational step toward achieving superior Process Optimization and dramatically cutting operational costs. Improving Quality and Sustainability with Artificial Intelligence While advanced automation handles the “how,” Artificial Intelligence (AI) in AdBlue Production handles the “what-if” and the “what’s-best.” Atmosfer Makina incorporates AI and Machine Learning (ML) to elevate both quality assurance and environmental sustainability. Predictive Quality Assurance: AdBlue Quality Control is paramount. Instead of relying solely on end-of-batch lab testing, our AI models analyze real-time data streams from inline sensors (conductivity, density, temperature) against historical data patterns. The AI can detect subtle anomalies—even those below the human or conventional PLC threshold—that indicate a potential deviation in the Urea Solution purity or concentration. By identifying these issues moments before they become critical, the system can automatically trigger micro-adjustments in the blending process, eliminating the need to discard entire batches due to contamination or incorrect concentration. This immediate feedback loop is a massive step toward Sustainable AdBlue production by virtually eliminating product waste. Energy Load Forecasting and Optimization: AI algorithms analyze historical energy consumption, production schedules, and even local utility rates to generate precise energy load forecasts. The system then determines the most Energy Efficient time to execute power-intensive tasks, such as bulk water purification or heating. In environments with variable energy costs, this intelligent scheduling can lead to substantial reductions in utility expenditure. The AI essentially acts as a sophisticated energy manager, constantly searching for the optimal balance between throughput and energy input. Preventing Scaling and Fouling: Scaling (crystallization) is a common issue in AdBlue Production Plant piping and equipment, increasing pump resistance and energy consumption. AI models track fluid dynamics, temperatures, and run-times to predict when and where scaling is likely to occur. This allows for proactive, targeted cleaning cycles, avoiding the energy penalty of forcing fluid through fouled pipes and extending the lifespan of crucial AdBlue Manufacturing Equipment. By embedding AI within our Smart Automation systems, Atmosfer Makina ensures not only compliance and quality but also a genuinely sustainable, waste-minimizing, and highly profitable operation. The Next Frontier: Operational Excellence and Compliance The intelligence embedded in our systems extends beyond the factory floor, reaching into operational management and global compliance. Remote Monitoring and Maintenance In the era of Industry 4.0, connectivity is key to minimizing Downtime and maximizing operational continuity. Our systems provide comprehensive Remote Monitoring capabilities, offering plant owners and our support teams unparalleled visibility into the operation of their AdBlue Production Plant. 24/7 Global Access: Using secure cloud-based platforms, authorized personnel can monitor every aspect of the plant—from pump performance and filter pressure to inventory levels and energy metrics—from anywhere in the world. This instantaneous access allows for rapid decision-making and troubleshooting, drastically reducing reaction time. Predictive Maintenance (PdM): Our Smart Automation systems are equipped with vibration sensors, temperature probes, and current monitoring devices on critical AdBlue Manufacturing Equipment (pumps, mixers, valves). The AI analyzes this operational data to detect subtle early signs of component wear or failure—such as unusual motor current draw or slight increases in pump vibration. This Predictive Maintenance approach means maintenance is scheduled just before a failure occurs, preventing catastrophic unplanned Downtime and costly emergency repairs. By ensuring components run efficiently until the ideal maintenance window, we optimize both maintenance costs and Energy Efficiency. PdM transforms maintenance from a cost center into a strategic operational

High-Purity Water Solutions with Atmosfer Engineering’s RO & EDI Systems

High-Purity Water Solutions with Atmosfer Engineering’s RO & EDI Systems Your Trusted Partner in Water Treatment Technology: Atmosfer Makina Atmosfer Engineering is committed to combining our expertise and innovative approach in water treatment technologies to meet the most demanding purity needs of industries. Water is a fundamental element of life and industrial processes, and we strive to provide it to you in its purest, cleanest form. With our deep focus on Reverse Osmosis (RO) and Electrodeionization (EDI) technologies, we hold a leading position in high-purity water solutions. Together with our expert team, we design systems specifically tailored to meet the unique requirements of each project, operating with an unwavering commitment to quality in water treatment. Who We Are and Our Expertise in Water Treatment With years of accumulated experience and a continuously developing team, Atmosfer Engineering has become a trusted name in the water treatment sector. Our core philosophy is to offer our customers not just a product, but a long-term solution partnership. With this understanding, we meticulously design and produce every system down to the finest detail. Atmosfer Engineering’s Commitment to Quality and Innovation Quality is our priority at every stage of our work. Every component we use, every design we implement, and every service we offer is selected to meet the highest industry standards. Continuous innovation is our most distinguishing feature. By closely following new technologies and integrating them with our own R&D efforts, we aim to provide our customers with more efficient, more economical, and more reliable water treatment systems. This commitment guarantees top-tier performance, especially in critical technologies like Reverse Osmosis and Electrodeionization. Why We Focus on Reverse Osmosis (RO) & Electrodeionization (EDI) Reverse Osmosis and Electrodeionization are the most effective and efficient methods for obtaining high-purity water. Reverse Osmosis effectively removes dissolved salts, bacteria, and other contaminants from water, while Electrodeionization produces ultra-pure water without the need for chemicals. The combination of these two technologies reliably and continuously meets the critical need for ultra-pure water in industrial processes. Our focus on these technologies is part of our vision to offer our customers the highest performance and the lowest operating costs. Delivering Reliable Solutions for Medical, Industrial, and Wastewater Applications Our solutions are not limited to industrial processes. We serve a wide range of applications, from hospitals to chemical factories, food and beverage production to wastewater treatment. We develop ultra-pure water solutions for sterilization processes in medical applications, high-purity water that increases process efficiency in industrial production, and wastewater treatment solutions compliant with environmental regulations. Our systems, custom-designed for each application, aim to maximize customer satisfaction. Our Industrial Reverse Osmosis (RO) Systems Our Industrial Reverse Osmosis systems are specifically designed for applications requiring high capacity and efficiency. These systems are one of the most critical technologies for water purification and process protection. At Atmosfer Makina, every Reverse Osmosis system we produce is designed for long-lasting and trouble-free operation. Designed for High Efficiency and Reliability Our Reverse Osmosis systems are engineered to maximize energy efficiency. By producing high-purity water with low energy consumption, they help reduce operating costs. Each system undergoes rigorous testing to ensure consistent and reliable performance. This guarantees the uninterrupted operation of industrial facilities. Wide Output Range from 25–200 GPM (36,000–288,000 GPD) Our solutions are offered with a wide range of output capacities to meet the needs of businesses of various scales. From 25 GPM (gallons per minute) to 200 GPM, we produce RO systems suitable for every need, from small and medium-sized businesses to large industrial facilities. This broad range allows our customers to find flexible solutions that can easily adapt to their future growth plans. Skid-Mounted, Pre-Piped, and Pre-Wired for Fast Installation We understand the value of time. That’s why our Reverse Osmosis systems are delivered skid-mounted, pre-piped, and pre-wired. This design significantly shortens installation time and eliminates the need for complex on-site assembly. As a result, your system can be commissioned quickly, and your production processes can continue uninterrupted. Custom Options: Two-Pass, CA, NF & UF Membranes to Fit Your Needs We know that every process has unique requirements. Therefore, in addition to our standard RO systems, we offer special options such as two-pass systems, Cellulose Acetate (CA) membranes, Nanofiltration (NF) membranes, and Ultrafiltration (UF) membranes. Two-pass systems are ideal for applications requiring extremely high-purity water. Different membrane types target specific contaminants in water, providing the most suitable treatment solution. EDI Technology – Our Approach to Ultra-Pure Water Electrodeionization (EDI) is a revolutionary technology that produces continuous deionized water without the need for chemical regeneration. At Atmosfer Engineering, we apply this technology with maximum efficiency, offering environmentally friendly and economical solutions to our customers. Continuous Deionized Water Without Chemicals One of the biggest advantages of EDI technology is that it eliminates the need for chemicals like acids and caustics to regenerate ion exchange resins. This not only reduces operating costs but also prevents the formation of chemical waste, ensuring an environmentally conscious operation. Our EDI systems provide a continuous flow of high-purity water, minimizing process interruptions. Seamless Integration with RO Systems Electrodeionization performs best when used in conjunction with a Reverse Osmosis (RO) system. The RO system provides primary demineralization of the water, optimizing the quality of water entering the EDI unit. This seamless integration increases the overall efficiency of the system and extends the lifespan of the EDI modules. At Atmosfer Engineering, we offer RO and EDI systems as a single integrated solution, providing turnkey solutions to our customers. Low Maintenance, Long-Term Cost Savings The absence of a need for chemical regeneration significantly reduces the maintenance costs of EDI systems. Additional costs such as resin regeneration, chemical storage, and waste disposal are eliminated. This leads to significant long-term cost savings for businesses. Furthermore, their modular design allows for easy intervention in case of a malfunction, quickly restoring the system to operation. Why Industries Trust Atmosfer Engineering Having served various industries for many years, we have gained a deep understanding of each sector’s specific needs. This experience enables us to

What Is ARLA 32? Everything You Need to Know About AdBlue Standards

What Is ARLA 32? Everything You Need to Know About AdBlue Standards The Drive for Cleaner Air: Understanding ARLA 32 and AdBlue Standards At Atmosfer Makina, we’re not just about machinery; we’re about pioneering solutions that drive progress while protecting our planet. In today’s world, diesel engines power a vast array of vehicles and machinery, from heavy-duty trucks and buses to agricultural equipment and industrial generators. However, these powerful engines have historically contributed to air pollution, particularly through nitrogen oxide (NOx) emissions. As global environmental regulations become increasingly stringent, the demand for effective emission control technologies has never been higher. This is where ARLA 32, more commonly known as AdBlue, plays a critical, indispensable role. For those in the transportation, logistics, agriculture, or construction sectors, understanding ARLA 32 and its associated standards is no longer optional—it’s essential for compliance, operational efficiency, and environmental stewardship. At Atmosfer Makina, we specialize in providing the robust and reliable production systems necessary to meet these precise specifications, helping our partners contribute to a cleaner, healthier future. Join us as we demystify ARLA 32, explore its purpose, delve into the crucial certification processes, and explain how Atmosfer Makina is your trusted partner in navigating this vital aspect of modern diesel technology. Definition and Purpose of ARLA 32 in Diesel Engines To truly grasp the significance of ARLA 32, we first need to define what it is and understand its vital purpose within modern diesel engines. What Exactly is ARLA 32? ARLA 32 is the acronym for “Agente Redutor Líquido de NOx Automotivo” 32. It is the Brazilian standard equivalent to AdBlue, which is the registered trademark for Diesel Exhaust Fluid (DEF) used in Europe and other regions. Essentially, ARLA 32/AdBlue/DEF is a high-purity, aqueous urea solution containing 32.5% high-purity urea and 67.5% demineralized water. This precise concentration is critical for its efficacy and is stipulated by various international standards, ensuring optimal performance and preventing damage to emission control systems. It’s important to differentiate ARLA 32 from other urea solutions. It is not a fuel additive, nor is it a fuel itself. Instead, it’s a separate fluid stored in a dedicated tank on diesel vehicles and machinery equipped with Selective Catalytic Reduction (SCR) technology. The Purpose: Reducing Harmful NOx Emissions The primary purpose of ARLA 32 is to significantly reduce harmful nitrogen oxide (NOx) emissions from diesel engine exhaust. NOx gases are major air pollutants that contribute to smog, acid rain, and respiratory illnesses. As environmental regulations like Euro V, Euro VI, and similar standards globally (e.g., EPA 2010 in the US) became mandatory, engine manufacturers adopted Selective Catalytic Reduction (SCR) technology as the most effective solution for meeting these stringent limits. Here’s how the SCR system works with ARLA 32: Injection: ARLA 32 is precisely injected into the hot exhaust gas stream. Hydrolysis: Heat causes the urea to convert into ammonia (NH3) and carbon dioxide (CO2). Catalytic Reaction: Ammonia reacts with harmful NOx gases. Conversion: NOx is converted into harmless nitrogen (N2) and water vapor (H2O). Without ARLA 32 of the correct purity and concentration, the SCR system cannot function effectively, leading to increased NOx emissions and potential engine derating or even shutdown, as dictated by onboard diagnostic systems. At Atmosfer Makina, our AdBlue production plants are designed to ensure this critical purity and concentration, making us a leader in emission reduction solutions. The Importance of Urea Quality in ARLA 32 Production Producing ARLA 32 / AdBlue to international standards starts with the right choice of urea. At Atmosfer Makina, we recommend and integrate the use of Prilled Urea Without UF (Ultra-Fine) as the optimal raw material for ARLA 32 production. It is critical to distinguish between prilled and granular urea. Prilled urea has a more uniform, smaller particle size and dissolves more efficiently, producing a homogeneous solution with minimal undissolved particles. In contrast, granular urea tends to have larger, irregular particles that can introduce impurities and may not dissolve fully, increasing the risk of clogging injectors or contaminating the SCR system. For this reason, Prilled Urea Without UF, free of ultra-fine dust, is preferred in certified ARLA 32 manufacturing. Additionally, the purity of urea is paramount. The raw material must meet strict limits for biuret, aldehydes, and heavy metals (such as iron, copper, and zinc) to avoid damaging SCR catalysts and ensure the final product complies with ISO 22241. Our systems and recommended practices are designed to monitor and maintain these impurity levels well within acceptable thresholds, safeguarding both equipment and the environment. Certification and Testing for Compliance The effectiveness of ARLA 32 hinges entirely on its purity and precise concentration. This is why strict AdBlue standards and rigorous certification processes are paramount. Non-compliant or contaminated ARLA 32 can lead to costly damage to sensitive SCR components, including the catalyst itself, resulting in expensive repairs and potentially voided warranties. At Atmosfer Makina, we ensure our clients produce certified ARLA 32 every time. The globally recognized standard for Diesel Exhaust Fluid is ISO 22241, which specifies strict requirements for composition, impurity limits, testing methods, and handling. Our AdBlue manufacturing systems are engineered to deliver a product that consistently meets these global benchmarks through advanced water purification, precise mixing, filtration, real-time monitoring, and certified materials of construction. Meeting Global Standards with Atmosfer Makina Systems At Atmosfer Makina, we integrate cutting-edge engineering and practical experience to deliver AdBlue manufacturing solutions that are synonymous with purity and reliability, ensuring compliance with ISO 22241 and national ARLA 32 regulations. Key features include: Ultra-pure water production (RO, DI, carbon filters) Precise urea dissolution and mixing Multi-stage filtration PLC-based automation and quality control High-grade stainless steel construction By choosing Atmosfer Makina, our clients gain confidence in producing certified ARLA 32/AdBlue, building trust with customers while contributing to cleaner air. Increase Market Competitiveness with Trusted AdBlue Solutions Our comprehensive AdBlue production solutions empower businesses to: Ensure regulatory compliance Build brand reputation and trust Optimize production efficiency Reduce long-term costs Support environmental responsibility Expand market reach Frequently Asked Questions (FAQs) About ARLA

SCR Anti-Crystallization Additives: Protecting Your Diesel Engine

SCR Anti-Crystallization Additives: Protecting Your Diesel Engine What Is Crystallization in SCR Systems? Welcome to the Atmosfer Makina blog, where we’re committed to providing the highest quality solutions and expert insights for modern diesel technology. As a leader in DEF production facilities and raw materials, we understand the critical importance of a properly functioning Selective Catalytic Reduction (SCR) system. One of the most significant challenges fleet managers and individual vehicle owners face is the issue of urea crystallization, which can lead to costly repairs and operational downtime. Overview of SCR (Selective Catalytic Reduction) Technology At its core, SCR is an advanced emission control technology designed to reduce harmful nitrogen oxide (NOx) emissions from the exhaust of diesel engines. It is an essential component for meeting strict global emissions regulations. The SCR system works by injecting a liquid reductant agent—typically a high-purity urea solution known as Diesel Exhaust Fluid (DEF), or AdBlue—into the exhaust stream. When this solution enters the hot exhaust gas, it undergoes a chemical reaction inside the catalytic converter, converting NOx into harmless nitrogen (N₂) and water (H₂O). This process is vital for ensuring your vehicle is compliant and environmentally responsible. The Role of AdBlue (DEF) in Emission Control AdBlue, also known as DEF, is the lifeblood of the SCR system. It is a 32.5% aqueous urea solution that is non-toxic, colorless, and safe to handle. It is stored in a dedicated tank on the vehicle and is dosed precisely into the exhaust system by an injection unit. The effectiveness of the SCR system is entirely dependent on the quality and consistent delivery of AdBlue. Our DEF production facilities are designed to produce the purest AUS32, ensuring a consistent and reliable supply for a wide range of applications. Causes of Crystallization in SCR Systems While AdBlue is designed to be an effective reductant, certain conditions can cause it to crystallize within the SCR system. This problem, often referred to as “urea crystal buildup,” typically occurs in areas of the exhaust system where temperatures are too low to fully evaporate the water in the DEF, leaving behind solid urea crystals. This is particularly common during short trips, frequent stops, or prolonged idling, especially in cooler climates. The injector nozzle, dosing unit, and the exhaust pipe leading to the SCR catalyst are all susceptible to this process. Potential Damage Caused by Urea Crystal Buildup The consequences of urea crystallization are severe and can be financially crippling. The most common issue is the clogging of the DEF injector nozzle, which disrupts the precise dosing of the solution. This leads to a cascade of problems, including: Reduced SCR Efficiency: A clogged injector can’t spray the correct amount of AdBlue, leading to a drop in NOx reduction performance. Engine Derate: Modern vehicles are programmed to detect SCR system malfunctions. If the system fails to reduce NOx emissions effectively, the vehicle’s Engine Control Unit (ECU) may trigger a “derate” mode, significantly limiting engine power and speed. Increased Maintenance Costs: Resolving crystallization often requires manual cleaning, component replacement, or even a full SCR system overhaul. This can lead to significant downtime and expensive repair bills. System Failure: In severe cases, the buildup can cause permanent damage to critical components, including the SCR catalyst itself. What Is an Anti-Crystallization Additive? This is where a specialized SCR anti-crystallization additive becomes an indispensable tool for maintenance and prevention. Definition and Function of SCR Anti-Crystallization Additives An SCR anti-crystallization additive is a specially formulated fluid designed to be mixed with AdBlue/DEF. Its primary function is to prevent the formation of solid urea crystals within the SCR system. By modifying the physical properties of the urea solution, these additives ensure that any residual DEF in the exhaust system remains in a liquid or gaseous state, even at lower temperatures, preventing it from solidifying and causing blockages. Common Chemical Components Used in These Additives These high-performance additives are typically made from a blend of specific surfactants, stabilizing agents, and wetting agents. These components are carefully selected to be compatible with the SCR system’s components and to not compromise the integrity of the AdBlue solution. Crucially, they are engineered to be non-corrosive and to not leave behind any harmful residue. How They Interact with DEF/AdBlue Solutions When an anti-crystallization additive is mixed with AdBlue, it works on a molecular level. It lowers the freezing point of the solution and enhances its ability to stay in a liquid form at lower temperatures. It also helps to “scour” the injector nozzle and other components, preventing the initial adhesion of urea particles that would otherwise lead to a crystalline buildup. This proactive approach ensures the continuous and accurate spraying of AdBlue, which is essential for optimal SCR performance. How Does the Additive Benefit SCR Systems? Using a quality SCR anti-crystallization additive offers a wide range of benefits that translate directly into savings and improved vehicle performance. Prevention of Injector and Line Clogging This is the most immediate and tangible benefit. By preventing urea crystal buildup, the additive keeps the DEF injector, dosing unit, and lines clean and clear. This ensures the precise and consistent injection of AdBlue, which is crucial for efficient NOx reduction and compliance. Protection During Low-Temperature Operations For our customers operating in cold climates or those whose vehicles frequently idle, an anti-crystallization additive is a game-changer. It provides a robust defense against crystallization, ensuring the SCR system operates reliably even in challenging weather conditions, where the risk of crystal formation is highest. Prolonged SCR System Life and Improved Reliability By keeping the entire SCR system free of crystalline blockages, the additive significantly extends the lifespan of expensive components like the injector, pump, and catalyst. This proactive maintenance strategy translates into improved reliability, fewer unexpected breakdowns, and a lower total cost of ownership for your vehicles. Why Use an Anti-Crystallization Additive? The question isn’t whether you can afford to use an anti-crystallization additive, but whether you can afford not to. Ensures Optimal NOx Reduction Efficiency The core purpose of the SCR system

Why Should Reverse Osmosis Systems Include a Pump?

Why Should Reverse Osmosis Systems Include a Pump? At Atmosfer Makina, we know that achieving the highest water quality is fundamental for your operations. Whether it’s for critical industrial processes, clean drinking water production, or specialized applications like DEF and fertilizer manufacturing, the purity of your water directly influences your success. This is where Reverse Osmosis (RO) systems excel, and often, the quiet powerhouse behind their effectiveness is the pump. Many clients ask us about the core components of an RO system. While RO membranes are crucial, the role of a high-quality pump is equally, if not more, vital. It’s the engine driving the entire water purification process. Without adequate pressure, even the most advanced RO system cannot perform efficiently. In this guide, we’ll explain why a high-pressure pump is not just an add-on but a fundamental component for optimal reverse osmosis performance, discussing the science, practical applications, and how Atmosfer Makina’s custom-engineered solutions ensure you have the ideal pump for your water treatment setup. The Role of Pressure in RO Systems To truly grasp why a pump is essential in a Reverse Osmosis system, we must first understand osmosis and, subsequently, reverse osmosis. Osmosis is a natural phenomenon where water molecules move across a semi-permeable membrane from an area of lower solute concentration to an area of higher solute concentration. This movement equalizes concentration, generating “osmotic pressure.” It’s a passive process, crucial for biological systems. Reverse osmosis, as the name implies, reverses this process. Our goal in water treatment is to separate impurities from water. To do this, we must overcome the natural osmotic pressure. This is precisely where the RO system pump becomes indispensable. By applying external pressure, greater than the natural osmotic pressure, to the concentrated side of the membrane, we force water molecules to move in the reverse direction—from higher solute concentration to lower. The semi-permeable membrane then acts as a selective barrier, allowing only pure water molecules to pass through while rejecting dissolved salts, contaminants, bacteria, and other impurities. This results in high-purity water. Pumped RO vs. Gravity-Based RO Systems While most industrial and commercial reverse osmosis systems rely heavily on pumps, it’s worth briefly discussing gravity-based systems, primarily found in smaller, rudimentary contexts, to highlight the critical advantages of pumped RO systems. Gravity-based water filtration systems, often using basic ceramic or activated carbon filters, work by slowly trickling water through filter media. They are simple, require no electricity, and are low-cost. They can remove larger particles and some basic contaminants, but they are entirely unsuitable for true reverse osmosis. The minimal pressures generated by gravity are far too low to overcome the osmotic pressure needed to push water through a semi-permeable RO membrane. Therefore, a gravity-fed system claiming to perform reverse osmosis is fundamentally misleading; genuine RO water treatment requires forced pressure. In contrast, pumped RO systems are the industry standard for any application requiring high-purity water in significant volumes. The advantages of incorporating a high-pressure booster pump are numerous: Superior Contaminant Rejection: Applied pressure directly dictates contaminant rejection efficiency. Consistent pressure ensures the membrane effectively separates even minute dissolved solids, providing exceptional water purity for industrial water purification. • Increased Permeate Production: Pumps dramatically increase the rate of purified water (permeate) production. Without sufficient pressure, permeate flow would be negligible, making the system impractical. Pumped systems can produce thousands of gallons per day, meeting large-scale demands. • Wider Applicability: Only pumped systems can effectively treat challenging water sources like brackish water, seawater, or highly contaminated industrial wastewater. The ability to generate and sustain high pressures makes desalination and advanced water recycling possible. • Consistent Performance: Pumps provide steady, controlled pressure, leading to consistent performance and predictable water quality. • Energy Efficiency (with proper design): While pumps consume energy, modern, high-efficiency pumps, combined with energy recovery devices, make the RO process remarkably energy-efficient for the volume and quality of water produced. Investing in the right pump minimizes long-term operational costs. • System Longevity: Maintaining optimal operating pressure helps in proper membrane cleaning (flushing) and prevents fouling, extending the lifespan of expensive RO membranes. Atmosfer Makina’s Industrial Reverse Osmosis Systems, including our ELITE SERIES SEA WATER DESALINATION, DIAMOND SERIES WATER PURIFICATION SYSTEMS and PLATINUM SERIES WATER PURIFICATION SYSTEMS, are all built around robust pumping solutions. We engineer these systems to deliver unparalleled performance and reliability, understanding that the pump is the heart of consistent, high-volume pure water production and overall water treatment technology. Choosing the Right Pump for Your Water Treatment Setup Selecting the appropriate pump for your Reverse Osmosis system requires careful consideration and expert knowledge. It’s not a one-size-fits-all solution, as the ideal pump depends on many factors specific to your application. At Atmosfer Makina, we guide our clients through this critical selection process, ensuring every component is perfectly matched to their unique needs for optimal RO system efficiency. Key factors influencing RO pump selection include: Feed Water Quality: The higher the TDS of your feed water, the higher the osmotic pressure, and therefore the higher operating pressure the pump must provide. • Desired Permeate Flow Rate: The amount of purified water required per day or hour directly determines the required pump flow capacity. • System Recovery Rate: A higher recovery rate can improve efficiency but may require more robust pressure from the pump. • Energy Efficiency: Using high-efficiency pumps and VFDs reduces electricity consumption and operational costs. • Material Compatibility: The pump’s materials must withstand the specific water chemistry, such as using super duplex stainless steel for seawater. • Reliability and Durability: Continuous operation demands robust construction to minimize downtime and maintenance. Atmosfer Makina’s expertise extends beyond just supplying equipment; we provide comprehensive water treatment solutions. Custom Engineered Solutions by Atmosfer Makina Atmosfer Makina prides itself on offering custom-engineered solutions for all your water treatment needs. We understand that every client’s requirements are unique, whether it’s the specific impurities in their water, the desired permeate quality, the volume of water needed, or their operational environment. This “tailored approach” is particularly

Why Urea Quality Matters in AdBlue® Production

Why Urea Quality Matters in AdBlue® Production At Atmosfer Makina, we recognize that in the world of modern diesel engines, AdBlue® (Diesel Exhaust Fluid or DEF/AUS32) is far more than just another fluid — it is an essential element for meeting stringent environmental regulations and ensuring peak vehicle performance. At the core of every high-quality AdBlue® solution is the purity of urea. Upholding the highest standards of urea quality is not just our business; it is our pledge to sustainability and to the reliable operation of your SCR (Selective Catalytic Reduction) systems. As global emission standards continue to tighten, SCR technology has become the industry standard for diesel vehicles. AdBlue®, a precisely formulated 32.5% solution of ultra-pure urea in demineralized water, is injected into the exhaust stream, converting harmful nitrogen oxides (NOx) into harmless nitrogen and water vapor. This process is extremely sensitive, and even minor impurities in urea can compromise its effectiveness, causing system damage, increased emissions, and costly downtime. For this reason, Atmosfer Makina proudly supplies Prilled Urea Without UF, specifically produced for AdBlue® manufacturing. This grade of urea is manufactured under strict ISO 22241 standards, ensuring that every batch delivers maximum performance, protects your SCR system, and keeps you in compliance with environmental regulations. The Impact of Urea Purity on SCR System Performance The performance and longevity of your SCR system are directly tied to the purity of the AdBlue® it uses, and therefore to the quality of the urea it is made from. Even minimal contamination can lead to serious problems: Catalyst Poisoning: Trace metals (like calcium, iron, copper, zinc, chromium, nickel) and other impurities can poison the sensitive SCR catalyst, reducing its ability to convert NOx effectively. Clogging and Damage: Dust, insoluble particles, or excessive biuret — a common urea byproduct — can crystallize inside the dosing system, blocking injectors and causing uneven spray patterns or total failure. Lower Efficiency: Impure urea reduces the chemical reaction efficiency, leading to higher emissions and potential regulatory non-compliance. Higher Maintenance Costs: Poor-quality urea leads to more frequent repairs, replacement parts, and downtime, negatively affecting your operational bottom line. Atmosfer Makina’s Prilled Urea Without UF meets the most stringent purity criteria: minimum nitrogen content of 46.2%, maximum biuret of 0.9%, maximum aldehydes of 15 mg/kg, and maximum moisture of 0.5%. We also carefully limit heavy metals, phosphate, and insoluble matter to prevent system degradation. Our product’s highly uniform particle size (98% between 1–2.8 mm) ensures fast dissolution and optimal performance in AdBlue® production — unlike general-purpose agricultural urea, which is unsuitable due to its impurities and slow solubility. How to Ensure Compliance with ARLA 32 Standards Complying with international standards such as ARLA 32 (equivalent to ISO 22241) is not optional — it is essential for maintaining the integrity of your SCR systems and for meeting global emissions regulations. Non-compliance can result in: Legal Penalties: Regulatory fines, vehicle bans, or recalls. Voided Warranties: Manufacturers may refuse warranty claims if poor-quality AdBlue® was used. Reputational Harm: AdBlue® producers who supply substandard products risk losing customer trust and market credibility. Atmosfer Makina supports your compliance efforts by supplying Prilled Urea Without UF manufactured specifically to meet ISO 22241 specifications. We include complete technical documentation with each batch, providing full transparency and traceability. When you choose Atmosfer Makina, you ensure that your AdBlue® production begins with certified, reliable raw materials — every time. Essential Equipment for High-Quality Urea Processing Producing world-class AdBlue® requires more than just high-purity urea — it demands precision and control throughout the production process. At Atmosfer Makina, we help our customers achieve operational excellence by supplying not only the right raw material but also the right guidance and expertise to maintain quality and compliance. We emphasize the use of reverse osmosis (RO) water purification systems, as high-purity demineralized water is just as critical as high-purity urea. Standard or tap water contains minerals and impurities that can harm SCR systems. That is why we recommend pairing our Prilled Urea Without UF with RO-treated water for guaranteed ISO-compliant AdBlue®. Certified AdBlue® Production Systems by Atmosfer Makina Choosing Atmosfer Makina means more than just buying a product — it means partnering with a company committed to your success. Our urea is rigorously manufactured, tested, and certified to deliver consistent, ISO 22241-compliant results, ensuring the quality and reliability of your AdBlue® production. We are here to assist you at every step — from technical consultation to ongoing support — helping you produce AdBlue® efficiently, economically, and with confidence. By supplying the best Prilled Urea Without UF and providing expert advice on production processes, we empower our clients to meet their environmental commitments without compromising performance or profitability. Trust Atmosfer Makina to help you produce cleaner, better-performing AdBlue® — and join us in creating a greener future. Frequently Asked Questions About Urea Quality and AdBlue® Production Why is urea purity so critical for AdBlue®? Atmosfer Makina: Because impurities can damage SCR systems, reduce efficiency, and lead to costly repairs. Only high-purity urea ensures proper NOx reduction. What makes “Prilled Urea Without UF” different from agricultural urea? Atmosfer Makina: Our product is ultra-pure and specifically produced for DEF, while agricultural urea contains unacceptable impurities. How can I be sure your urea meets ISO 22241? Atmosfer Makina: Each batch comes with full technical documentation and is manufactured to strict ISO 22241 standards. Can I use regular water to mix AdBlue®? Atmosfer Makina: No. You must use demineralized water, ideally from RO systems, to avoid introducing contaminants. What particle size is recommended for urea in AdBlue®? Atmosfer Makina: Our urea is 98% within 1–2.8mm for optimal dissolution and performance. What happens if poor-quality urea is used? Atmosfer Makina: It can clog injectors, poison catalysts, void warranties, and cause higher emissions. Does your urea dissolve quickly in water? Atmosfer Makina: Yes. Its uniform prilled structure ensures fast, even dissolution — superior to granular urea. What support do you offer to AdBlue® producers? Atmosfer Makina: We provide consultation, technical

What Is Urea in AdBlue? The Key Component Behind Emission Reduction

What Is Urea in AdBlue? The Key Component Behind Emission Reduction At Atmosfer Engineering, we are proud to be a part of the technological transition toward cleaner and more sustainable transportation. A critical element in reducing emissions from diesel engines is AdBlue, a solution made primarily from urea. In this article, we will explore what urea is, how it functions in AdBlue, and why its purity and compliance with ARLA 32 standards are crucial for achieving real environmental benefits. Whether you’re a fleet manager, an industrial buyer, or simply someone curious about the mechanics behind emission control technologies, this comprehensive guide will clarify how urea in AdBlue plays a pivotal role in reducing harmful NOx emissions and how Atmosfer Engineering supports this process with high-purity supply systems. What Is Urea and How Is It Used in AdBlue? Urea (chemical formula: CO(NH₂)₂) is a nitrogen-based compound widely used in fertilizers, plastics, and—most importantly for this context—emission reduction fluids. In AdBlue, which is also known globally as Diesel Exhaust Fluid (DEF), urea is mixed with deionized water to form a 32.5% urea solution. This mixture is non-toxic, colorless, and safe to handle, yet it serves a powerful purpose in modern diesel vehicles. AdBlue is stored in a dedicated tank within the vehicle. When injected into the exhaust system, it undergoes a thermal reaction, releasing ammonia (NH₃). This ammonia then reacts with Nitrogen Oxide (NOx) gases within the Selective Catalytic Reduction (SCR) system, converting them into harmless nitrogen (N₂) and water vapor (H₂O). This is where urea comes into the picture: it’s the active compound that triggers the breakdown of toxic gases. How Urea Helps Reduce NOx Emissions in Diesel Engines Modern diesel engines are required to meet strict emission standards, such as Euro VI in Europe and EPA 2010 in the U.S. These regulations target the drastic reduction of NOx emissions, which are responsible for smog formation and respiratory problems. Here’s how urea works in AdBlue systems to meet those regulations: Injection Phase AdBlue is precisely injected into the hot exhaust stream after combustion. Hydrolysis Urea decomposes into ammonia (NH₃) and carbon dioxide (CO₂) under high heat. Selective Catalytic Reduction (SCR) Ammonia reacts with NOx in the SCR catalyst, producing nitrogen and water. This entire chemical process is incredibly efficient, capable of reducing NOx emissions by up to 90%. However, its effectiveness depends heavily on the purity of the urea used. Importance of ARLA 32 Compliance in Urea Production Not all urea is suitable for AdBlue production. The AdBlue solution must meet strict ISO 22241 standards for purity and composition. One key certification is ARLA 32 (Agente Redutor Líquido de Óxidos de Nitrogênio Automotivo), commonly used in Latin America and increasingly recognized in international supply chains. At Atmosfer Engineering, we ensure that our urea complies with ARLA 32 standards. Why is this important? High-purity urea prevents the buildup of residues in the SCR system. Impurities like biuret or calcium can damage injectors and catalysts. Deionized water must also meet conductivity thresholds to maintain the integrity of the solution. Failing to comply with ARLA 32 or ISO 22241 standards can lead to: Costly vehicle repairs Increased emissions Reduced fuel efficiency Warranty voidance Our focus on certified and laboratory-tested urea protects both your equipment and the environment. High-Purity Urea Supply with Atmosfer Makina Systems At Atmosfer Engineering, we don’t just sell a machine—we provide integrated emission control solutions. Our AdBlue production plants are designed to ensure consistent quality, safe storage, and optimal dosing. Why Choose Atmosfer Makina? Advanced Mixing Systems We offer fully automated AdBlue preparation units for commercial and industrial facilities. Bulk Storage Solutions Custom-designed tanks, pumps, and dispensers tailored for your fleet needs. Laboratory-Grade Testing In-house testing equipment ensures that every batch of urea meets ARLA 32 and ISO 22241 standards. Logistics and Distribution National delivery service with temperature-controlled packaging to preserve product integrity. We invite you to explore our full range of solutions at www.atmosfermakina.com. Whether you’re producing AdBlue in-house or sourcing it for your fleet, we’re here to support your mission for cleaner, greener transport. Frequently Asked Questions (FAQ) What is the role of urea in AdBlue? Urea serves as the active ingredient that converts NOx emissions into harmless nitrogen and water vapor through the SCR system. Is AdBlue harmful to humans or the environment? No, AdBlue is non-toxic and biodegradable when handled properly. What percentage of urea is in AdBlue? AdBlue contains 32.5% high-purity urea and 67.5% deionized water. Can I use fertilizer-grade urea for AdBlue production? Absolutely not. Only ARLA 32-certified or ISO 22241-compliant urea is safe and effective. What happens if I use contaminated urea? Impurities can clog injectors, damage the catalyst, and void your vehicle’s warranty. Does AdBlue improve fuel efficiency? Indirectly yes. A well-functioning SCR system reduces engine strain and can lead to better fuel economy. How should AdBlue be stored? In a cool, dry place away from direct sunlight and not below -11°C or above 30°C. Can I produce AdBlue on-site? Yes. Atmosfer Makina provides production units for on-site manufacturing under full compliance. What is ARLA 32 and how is it different from ISO 22241? ARLA 32 is the Brazilian regulation aligned with ISO 22241 but emphasized in Latin markets. Do all diesel vehicles require AdBlue? Only those equipped with SCR systems, typically Euro V and newer diesel engines. Can AdBlue freeze? Yes, it freezes at around -11°C but can be thawed without degradation. How long does AdBlue last in storage? Typically 12-36 months if stored properly. For more technical details, system configurations, or urea sourcing inquiries, please visit our website: 👉 https://atmosfermakina.com/ Or contact us directly via: 📞 0530 200 2435 📧 [email protected]

The Future of AdBlue Production: Automation, Smart Control, and Efficiency Trends

The Future of AdBlue Production: Automation, Smart Control, and Efficiency Trends As the demand for AdBlue continues to rise, manufacturers are compelled to look beyond the production floor and examine how artificial intelligence (AI), integrated logistics, and regulatory frameworks are shaping the industry’s future. These elements are crucial not only for maintaining product integrity but also for ensuring competitive advantage in a rapidly evolving global market. Artificial Intelligence: Predictive and Prescriptive Production Artificial intelligence is no longer a futuristic idea in industrial settings—it is becoming an operational necessity. In AdBlue production, AI is being used to analyze massive datasets from sensors and control systems to optimize process variables in real time. Predictive analytics can forecast equipment failures before they occur, allowing for timely maintenance and preventing costly downtimes. Moreover, prescriptive AI tools recommend optimal production settings based on historical trends, weather conditions, and raw material quality. This ensures consistent product quality and reduces energy consumption. As environmental compliance becomes stricter, AI-driven adjustments help facilities remain within legal limits for emissions, energy use, and waste generation. Some producers are even using machine learning algorithms to predict fluctuations in urea purity, allowing them to adjust mixing ratios automatically. This level of smart control transforms AdBlue manufacturing from a reactive task into a predictive science, significantly enhancing operational efficiency and sustainability. Logistics and Digital Integration While production optimization is crucial, so is efficient distribution. AdBlue is often transported to fuel stations, fleet depots, and industrial consumers, and maintaining quality during transit is just as important as during production. Therefore, many companies are integrating digital logistics solutions to track and monitor shipments in real time. Temperature-controlled tanks, GPS tracking, and remote quality monitoring are now becoming standard in logistics. These systems ensure that the AdBlue remains uncontaminated and within the required specification from the moment it leaves the plant to the moment it is delivered. Manufacturers like Atmosfer Makina, a forward-thinking player in the AdBlue equipment sector, emphasize the importance of full-cycle control—from production to delivery. To learn more about their innovative systems or get in touch with their experts, you can reach them via mobile/WhatsApp at +90 541 947 0414 or +90 539 549 05 12, or email them at [email protected] for general inquiries, [email protected] for business cooperation, and [email protected] for technical support. Regulatory Pressures and Future Compliance As global environmental regulations tighten, AdBlue producers must stay ahead of legislative changes. In Europe, the Euro VI standards are pushing diesel engines to emit nearly zero NOx emissions. Similar regulatory trends are taking shape in North America, South Korea, and increasingly, in developing markets. Future compliance will likely require continuous quality reporting, digital traceability of production batches, and stricter ISO certification adherence. This will push more manufacturers to invest in integrated software solutions that automatically generate compliance reports and store production data securely for audits. Facilities that cannot meet these demands may find themselves locked out of key export markets. Conversely, those that prepare now—by embracing automation, smart analytics, and rigorous quality control—will not only meet new standards but become industry leaders. Sustainability and Circular Production Models The next frontier in AdBlue production involves not only reducing the environmental impact of operations but also contributing positively to the circular economy. This includes utilizing waste heat from other industrial processes to power AdBlue production, reusing purified wastewater, and investing in carbon-neutral production models. Some advanced facilities are already integrating solar power and battery storage systems to operate partially or fully off-grid. These systems reduce operational carbon footprints and provide resilience against energy price volatility. The integration of lifecycle analysis (LCA) tools also helps companies calculate and reduce their environmental impact per liter of AdBlue produced. Looking Ahead: Digital-First, Data-Driven Production The AdBlue industry is undeniably moving toward a digital-first era. From sensor-based production control to blockchain-enabled supply chain transparency, the emphasis is on using data to drive every decision. Companies that prioritize these technologies are setting the stage for scalable, agile, and compliant operations. What makes the future especially promising is the increasing affordability and accessibility of these technologies. Cloud platforms, remote access systems, and mobile applications allow facility managers to monitor and adjust production parameters from anywhere in the world. For example, Atmosfer Makina supports remote system configurations and diagnostics for their clients, ensuring constant performance optimization and minimal downtime. For organizations seeking guidance or customized AdBlue solutions, Atmosfer Makina offers expert consultation. Feel free to reach out to their team via WhatsApp at +90 541 947 0414 / +90 539 549 05 12 or email at [email protected] for more information. Conclusion The transformation of AdBlue production is well underway, driven by automation, smart technologies, and sustainability goals. As manufacturers adapt to new challenges and opportunities, those who invest in intelligent systems, efficient logistics, and proactive compliance will thrive in a competitive global market. Whether you’re just entering the AdBlue industry or looking to upgrade your existing infrastructure, embracing these trends today will prepare your business for the demands of tomorrow. And when expert support is needed, experienced partners like Atmosfer Makina are ready to assist with cutting-edge solutions and personalized service. Frequently Asked Questions (FAQ) What is AdBlue and why is it important? AdBlue is a urea-based fluid used in Selective Catalytic Reduction (SCR) systems to reduce harmful nitrogen oxide (NOx) emissions in diesel engines. It is essential for meeting environmental standards like Euro VI and helps reduce air pollution caused by diesel vehicles. How is modern technology changing AdBlue production? Advancements such as automation, smart control systems, and AI-driven analytics are revolutionizing AdBlue production. These technologies ensure higher precision, consistent quality, energy efficiency, and predictive maintenance, reducing both cost and environmental impact. What role does Atmosfer Makina play in AdBlue production? Atmosfer Makina specializes in advanced AdBlue production and storage equipment. They provide innovative, reliable, and efficient systems tailored to the needs of modern production facilities. You can contact them via WhatsApp at +90 541 947 0414 or +90 539 549 05 12, or by email at [email protected]. Can AdBlue

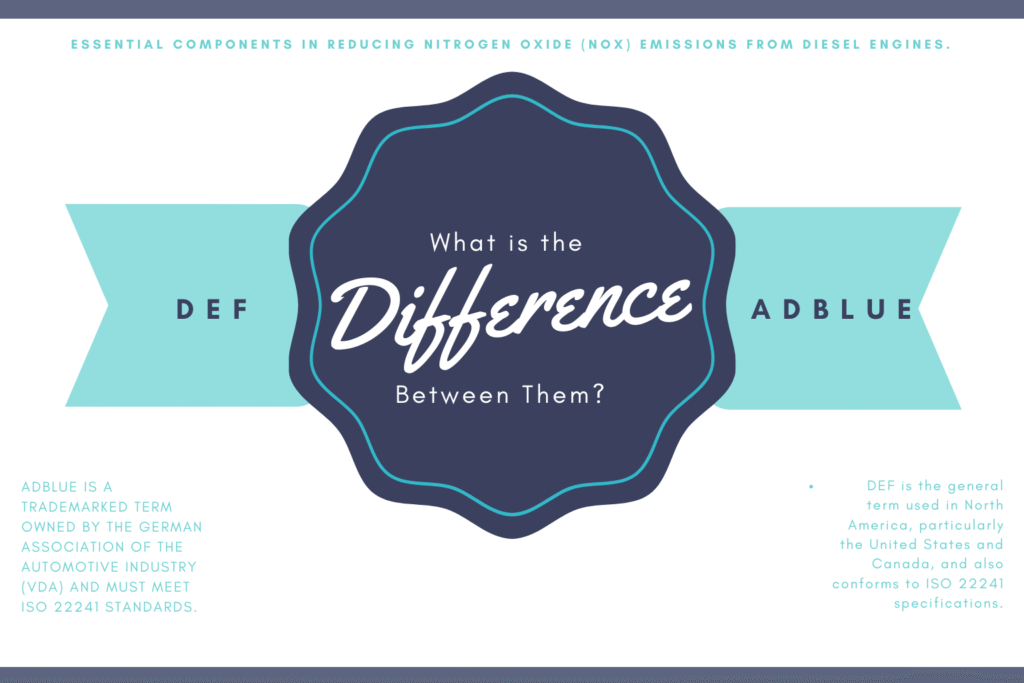

DEF vs. AdBlue: What Are the Technical Requirements for Production Machinery?

DEF vs. AdBlue: What Are the Technical Requirements for Production Machinery? As global emission regulations tighten, Diesel Exhaust Fluid (DEF) and AdBlue have become essential components in reducing nitrogen oxide (NOx) emissions from diesel engines. While the terms are often used interchangeably, there are subtle differences between them, especially in terms of branding and compliance. However, when it comes to the technical requirements for production machinery, precision and standardization remain universally critical. Understanding the Difference Between DEF and AdBlue At their core, both DEF and AdBlue are composed of a 32.5% high-purity urea solution in 67.5% deionized water. The key distinction lies in regional branding and certification: AdBlue is a trademarked term owned by the German Association of the Automotive Industry (VDA) and must meet ISO 22241 standards. DEF is the general term used in North America, particularly the United States and Canada, and also conforms to ISO 22241 specifications. So, from a chemical and functional standpoint, there is no difference between AdBlue and DEF. However, only products certified under the AdBlue license can legally carry the AdBlue name. Technical Requirements for Production Machinery Whether producing AdBlue or DEF, machinery must be specifically designed to maintain the purity and composition required by ISO 22241. Below are the key technical requirements: Urea Quality and Storage Use only automotive-grade urea with very low biuret and heavy metal content. Urea should be stored in closed, climate-controlled tanks to prevent contamination and moisture absorption. Equipment should include urea feeding pumps made from non-reactive materials (e.g., stainless steel or high-density polyethylene). Water Purification System Water must be demineralized to remove any ions, salts, or metals. Recommended purification methods include: Reverse Osmosis (RO) Ion Exchange Resins UV Sterilization (optional) Conductivity of the purified water should be below 0.5 µS/cm to comply with ISO standards. Blending Unit Accurate mixing is critical. Machinery should maintain a 32.5% urea to 67.5% water ratio with less than ±0.2% deviation. Use flow meters, conductivity sensors, and temperature controllers to monitor and adjust the blending process in real time. Blending tanks must be non-corrosive, ideally made of polypropylene or stainless steel. Automation and Smart Controls Modern DEF/AdBlue production lines should feature PLC (Programmable Logic Controller) systems for automation. Integration with IoT sensors and remote monitoring enables predictive maintenance and real-time quality assurance. Software should support data logging, batch tracking, and compliance reporting for audits. Filling and Packaging Equipment Filling systems must prevent contamination and maintain sterility throughout the process. Bottling machines, IBC (Intermediate Bulk Container) fillers, and tanker loaders should use closed-loop systems. Accurate volume control is essential to reduce waste and meet customer specifications. Material Compatibility All piping, valves, pumps, and tanks must be constructed from AdBlue/DEF-compatible materials. Avoid copper, brass, aluminum, and mild steel as they may react with the fluid and compromise its purity. Trusted Equipment Providers: Atmosfer Makina For companies seeking robust, compliant, and automated production solutions, Atmosfer Makina offers state-of-the-art DEF/AdBlue manufacturing systems. Their machines are designed specifically to meet ISO 22241 requirements, support remote access, and minimize human error in blending and bottling processes. For detailed technical consultation or to request a quote, you can contact Atmosfer Makina via: Mobile / WhatsApp: +90 541 947 0414 +90 539 549 05 12 Email: General inquiries: [email protected] Marketing & partnerships: [email protected] Technical support: [email protected] Why Purity Matters: The Impact of Contaminants on SCR Systems In DEF/AdBlue production, even microscopic impurities can have serious consequences. Contaminated fluid can clog injectors, damage the catalyst in Selective Catalytic Reduction (SCR) systems, and trigger vehicle fault codes. As a result, maintaining ultra-high purity is not optional—it’s essential. Production machinery must be designed to minimize contact with air, metals, and non-compatible materials. Additionally, regular cleaning protocols, closed-loop piping, and sterile filling equipment are all part of maintaining product integrity. Investing in precision equipment saves costs in warranty claims and protects your brand reputation. Batch vs. Continuous Production: Which Method Is Better for You? Choosing between batch and continuous production setups depends largely on your output volume, budget, and operational flexibility. Batch Production: Ideal for small to medium-scale operations. Easier to manage and allows frequent formula checks. Less initial investment. Continuous Production: Suitable for high-demand environments. Offers greater efficiency, consistency, and automation potential, but requires more advanced infrastructure. Companies like Atmosfer Makina offer scalable systems that can accommodate both models, making it easier to grow as your business expands. Maintaining ISO 22241 Compliance: Equipment Checklist To legally sell AdBlue or DEF under recognized standards, producers must comply with ISO 22241. Here’s a simplified checklist your equipment should meet: ✅ Demineralized water purification unit (RO or ion exchange) ✅ Corrosion-resistant tanks and piping (HDPE, stainless steel) ✅ Precision dosing system to maintain 32.5% urea concentration ✅ Flow meters, conductivity sensors, and temperature controllers ✅ Cleanroom-grade filling and packaging systems ✅ Secure storage with temperature control and UV protection ✅ Digital batch tracking and compliance reporting tools Failing to meet these standards may result in product rejection or regulatory penalties. Common Mistakes in DEF/AdBlue Production and How to Avoid Them Using tap water or semi-purified water – This increases mineral content and conductivity, leading to ISO non-compliance. Inadequate blending control – Manual mixing often results in improper ratios and poor product quality. Incorrect material selection – Using aluminum or copper in piping systems leads to contamination. Poor sealing during packaging – Open systems allow air and particles to enter, ruining batch purity. No data logging or batch documentation – Failing to track quality can result in liability during audits or customer complaints. Avoiding these mistakes is easier with modern, automated machinery. Atmosfer Makina’s systems are designed to address each of these issues proactively. Cost Optimization: How Automation Lowers Operational Expenses Though automation may seem like a major upfront investment, it significantly reduces operational costs over time by: 🔧 Minimizing labor through smart control panels and remote monitoring 🕒 Reducing downtime thanks to predictive maintenance alerts 📉 Preventing overuse of raw materials via precision metering ✅ Ensuring consistent product quality, avoiding reworks or recalls